A kind of production method of spcc material deep drawing tin-plated substrate

A technology of a tin-plated substrate and a production method, which is applied in the production field of SPCC material deep-drawing tin-plated substrates, can solve the problems that the use requirements of deep-drawing products cannot be met, the steel coil is seriously stuck to the steel, and the production difficulty is large, and the finished product can be improved. The effect of reducing the production difficulty and reducing the production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: The chemical composition and mass percentage of the SPCC material hot-rolled steel coil: C 0.03%, Mn0.30%, Si 0.03%, P 0.02%, S 0.01%, and the balance is Fe and unavoidable Impurities.

[0018] The production method of the tin-plated substrate for deep drawing of SPCC material adopts the following specific process steps.

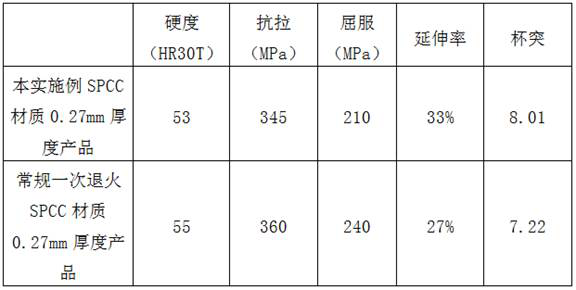

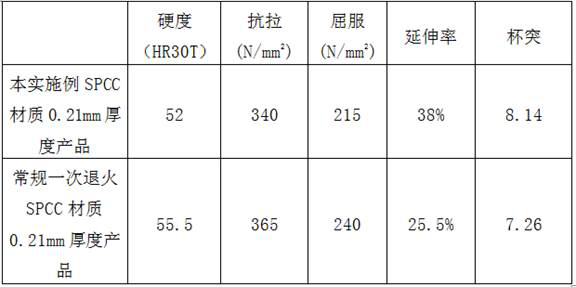

[0019] Use ordinary SPHC material 2.75mm hot-rolled steel coil; the hot-rolled steel coil is subjected to the first cold-rolling treatment by the HC reversible cold-rolling machine, and is cold-rolled into a steel plate with a thickness of 0.75mm; then put into the full-hydrogen hood In the annealing furnace, heat up to 640°C at a rate of 100°C / h, hold for 16 hours, cool down to 500°C with the furnace after the heat preservation is over, replace the heating cover with a cold air cover, cool to 350°C with air, and then cool to 250°C with the furnace ℃, start water cooling until it cools to 80 ℃, and then come out of the furnace; then return...

Embodiment 2

[0023] Example 2: The chemical composition and mass percentage of the SPCC material hot-rolled steel coil: C 0.07%, Mn0.15%, Si 0.01%, P 0.01%, S 0.009%, the balance is Fe and unavoidable Impurities.

[0024] The production method of the tin-plated substrate for deep drawing of SPCC material adopts the following specific process steps.

[0025] The 2.5mm hot-rolled steel coil of ordinary SPHC material is used; the hot-rolled steel coil is subjected to the first cold rolling treatment by the HC reversible cold rolling mill, and is rolled into a steel plate with a thickness of 0.70mm through three passes; In the bell-type annealing furnace, heat to 650°C at a rate of 100°C / h, hold for 15 hours, cool down to 500°C with the furnace after the heat preservation is over, replace the heating cover with a cold air cover, air cool to 350°C, and then cool with the furnace To 250 ℃, start water cooling, until cooled to 80 ℃, out of the furnace; then return to the HC reversible cold rolli...

Embodiment 3

[0028] Example 3: The chemical composition and mass percentage of the SPCC material hot-rolled steel coil: C 0.05%, Mn0.22%, Si 0.02%, P 0.011%, S 0.007%, and the balance is Fe and unavoidable Impurities.

[0029] The production method of the tin-plated substrate for deep drawing of SPCC material adopts the following specific process steps.

[0030] Use ordinary SPHC material 2.35mm hot-rolled steel coil; the hot-rolled steel coil is subjected to the first cold-rolling treatment through the HC reversible cold-rolling machine, and is rolled into a steel plate with a thickness of 0.65mm through three passes; then put into a full-hydrogen cover In the type annealing furnace, heat up to 660°C at a rate of 100°C / h, hold for 14 hours, and cool to 500°C with the furnace after the heat preservation is over, replace the heating cover with a cold air cover, air cool to 350°C, and then cool with the furnace to 250°C, start water cooling until it cools to 80°C, and then come out of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com