Temperature-sensitive diaphragm, preparation method thereof and application of temperature-sensitive diaphragm

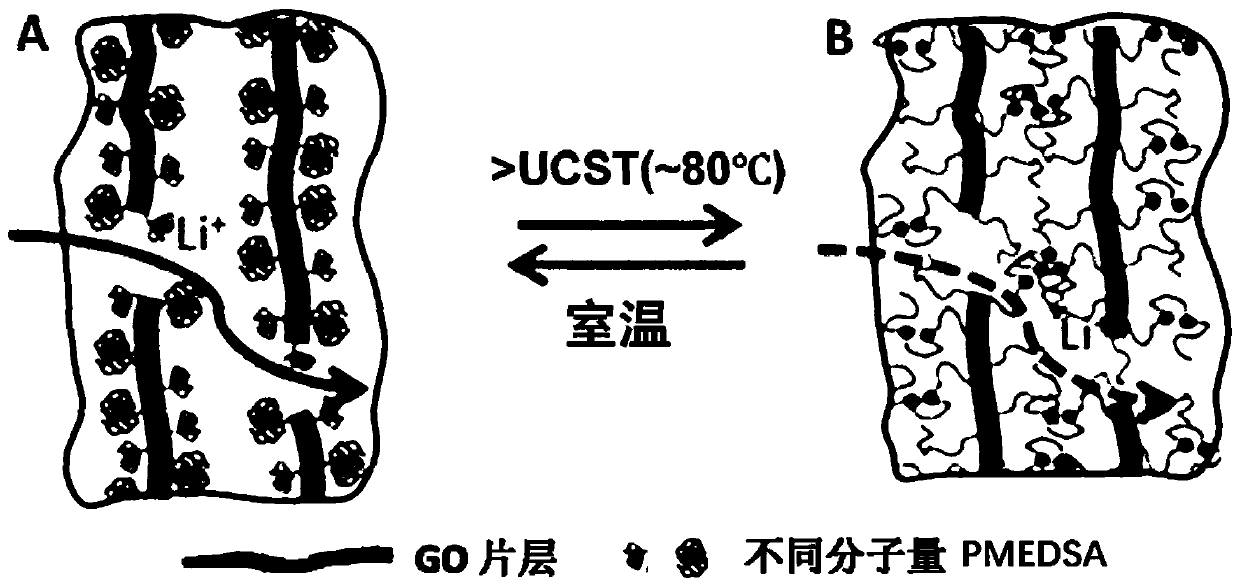

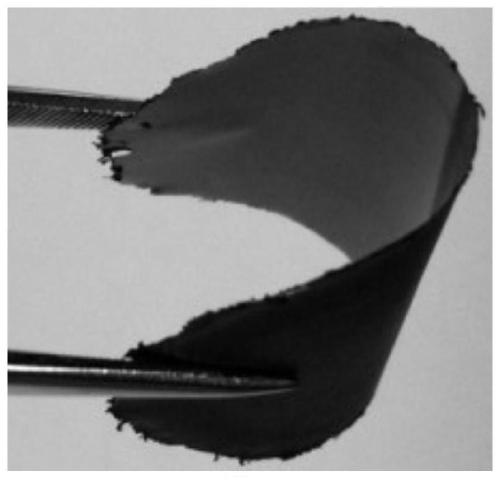

A diaphragm and temperature-sensitive technology, applied in the field of temperature-sensitive diaphragms and their preparation, can solve the problems that the battery cannot be restored to use, the heat sealing film is not reversible, etc., and achieves excellent flexibility, good reversibility, and strong controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

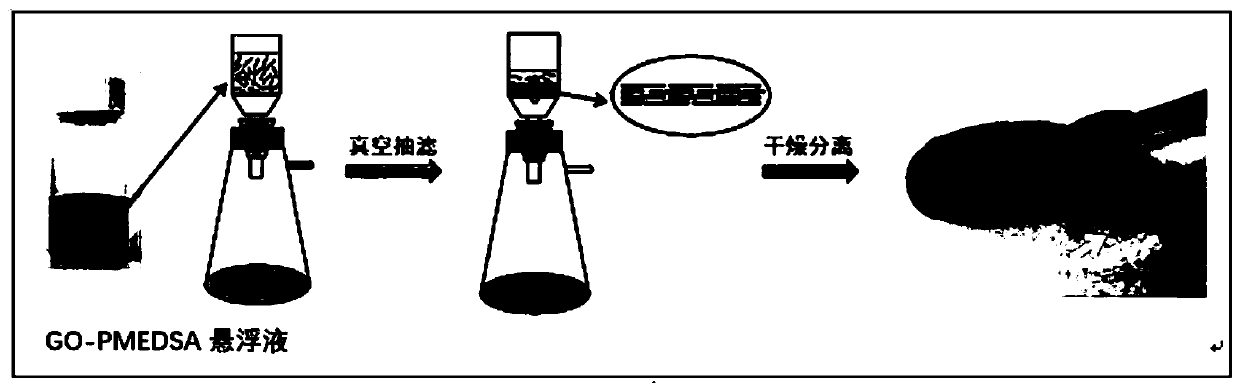

[0056] Embodiment 2 of the present invention is: a method for preparing a temperature-sensitive diaphragm, and the specific steps include:

[0057] (1) Graphene oxide is hydroxylated, specifically:

[0058] Suspend 0.50 g of graphene oxide evenly in 250 mL of deionized water, ultrasonicate for 30 minutes, add 6.3 g of 4-aminophenethyl alcohol and 75 mL of isoamyl nitrite to the graphene oxide suspension, and fill the reactor with a condenser. Inject nitrogen, heat at 60°C, and reflux for 3 hours. After the reaction, the mixture is separated by vacuum filtration, and washed with 250mL acetone, 250mL dimethylformamide, 250mL deionized water and 250mL acetone several times. Finally, the reaction product was washed with 250 mL of ether, and dried in a vacuum oven to obtain hydroxylated graphene oxide, which was named GO-OH.

[0059] (2) introducing organic Br groups on the graphene oxide surface after hydroxylation treatment, specifically:

[0060] Disperse 220 mg of GO-OH obtai...

Embodiment 3

[0064] Embodiment 3 of the present invention is: a method for preparing a temperature-sensitive diaphragm, and the specific steps include:

[0065] (1) Graphene oxide is hydroxylated, specifically:

[0066] Suspend 0.50g of graphene oxide evenly in 250mL of deionized water, ultrasonicate for 30 minutes, add 6.3g of 4-aminophenethyl alcohol and 75mL of isoamyl nitrite to the graphene oxide suspension, and fill the reactor with condenser Nitrogen, heated at 60°C, and refluxed for 3 hours. After the reaction, the mixture was separated by vacuum filtration, and washed with 250mL acetone, 250mL dimethylformamide, 250mL deionized water and 250mL acetone several times. Finally, the reaction product was washed with 250 mL of ether, and dried in a vacuum oven to obtain hydroxylated graphene oxide, which was named GO-OH.

[0067] (2) The surface of graphene oxide introduces organic Br groups, specifically:

[0068] Disperse 220 mg of GO-OH obtained in step (1) in 50 mL of tetrahydrofu...

Embodiment 8

[0104] Embodiment 8 of the present invention is: a preparation method of a battery, the specific steps include: using reduced graphene oxide as the positive electrode of the battery, lithium sheets as the negative electrode of the battery, commercial 1M LiFP 6 The EC:DEC (volume ratio is 1:1, add 10% FEC) solution is electrolyte, and the temperature-sensitive separator GO-PMEDSA prepared in embodiment 7 is sandwiched between two glass fiber membranes (GF) and assembled as battery separator Button cell test temperature sensitive separator GO-PMEDSA separator performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com