Preparation method of high-power external application type lead-carbon battery negative electrode

A lead-carbon battery, high-power technology, applied in the field of preparation of high-power external lead-carbon battery negative electrode, to achieve the effects of avoiding reduction, improving effective utilization, and inhibiting sulfation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

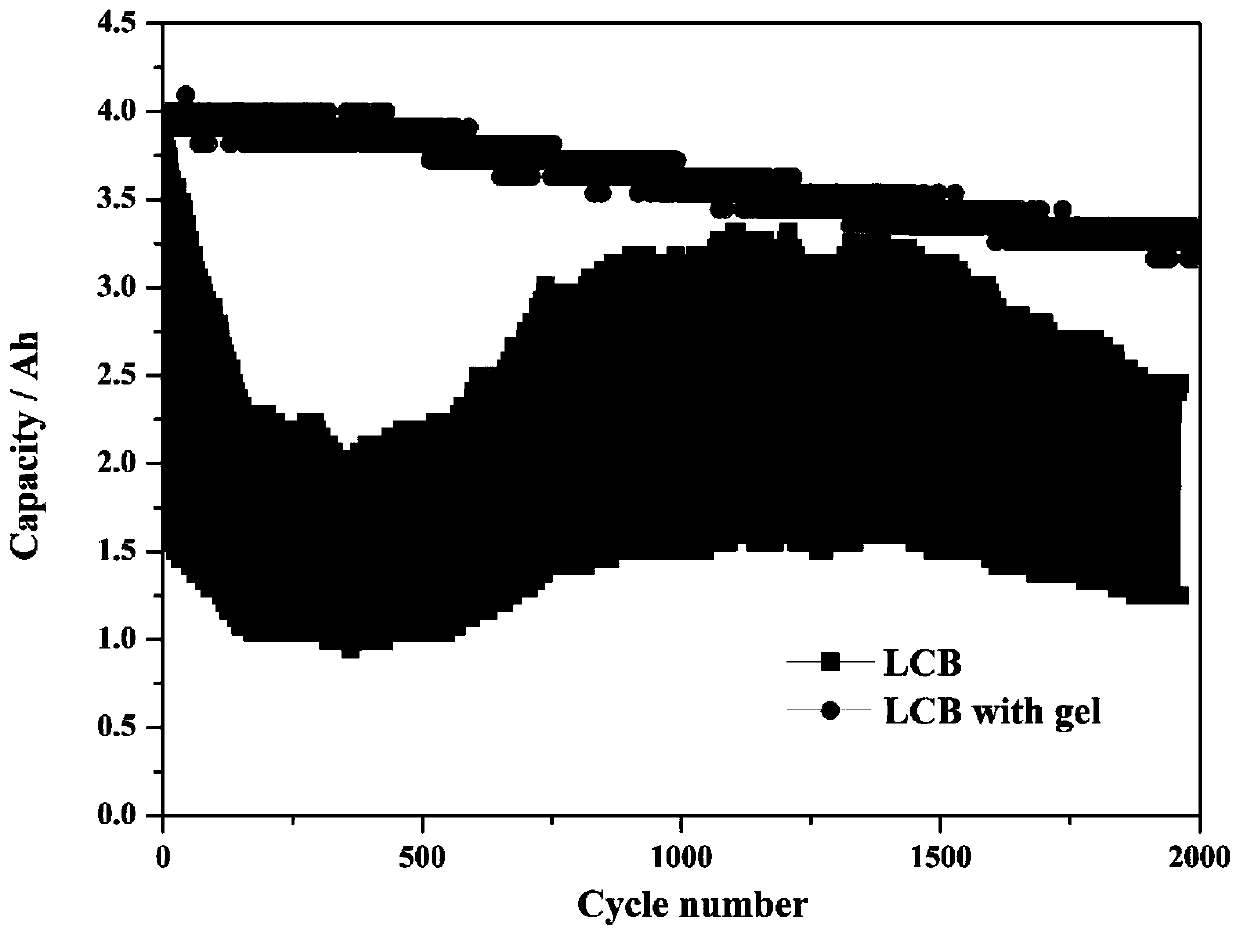

Examples

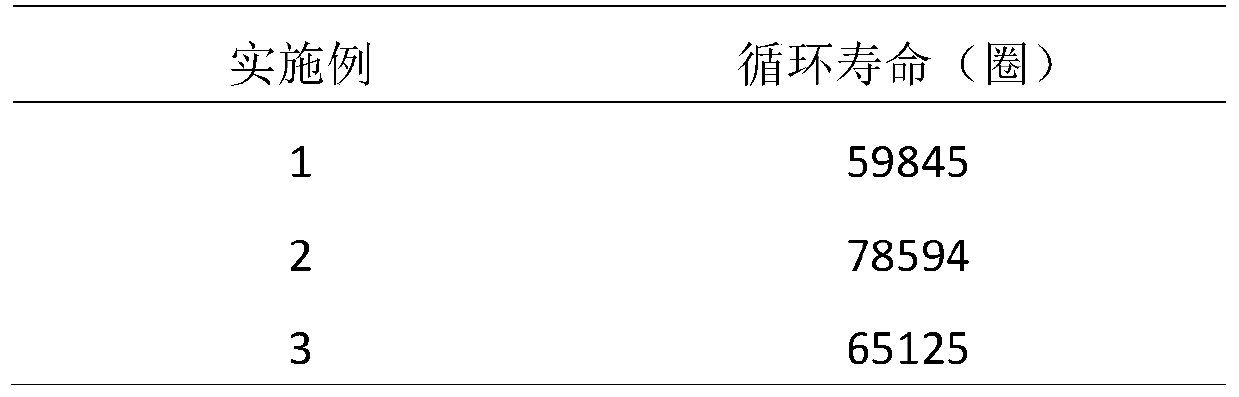

Embodiment 1

[0037] 85 lead powder, 3wt% humic acid, 3wt% 10mm long dacron, 3wt% barium sulfate, 3wt% sodium lignosulfonate, 3wt% acetylene black are mixed uniformly to make active substance, mixed The active substance is slowly added to its total weight of 8wt% water and 12.5wt% 4.6mol / L sulfuric acid and stirred evenly to form a lead paste;

[0038] 85wt% 1960m 2 / g activated carbon material, 10wt% carbon black, and 5wt% polytetrafluoroethylene are mixed evenly in dehydrated alcohol, and the quality of dehydrated alcohol is 180 times that of the activated carbon material. The absolute ethanol was evaporated to dryness by constant stirring at 90°C to obtain a homogeneous mixture. Add 0.3ml / mg of absolute ethanol to the mixture, roll it into a tablet, and then dry it at 90°C for 12 hours to obtain a carbon sheet. The loading of the mixture in the carbon sheet is 3mg / cm 2 ;

[0039] 50wt% polystyrene, 25wt% acetylene black, 25wt% 1530m 2 / g activated carbon material was mixed with suff...

Embodiment 2

[0051] 85 lead powder, 3wt% humic acid, 3wt% 10mm long dacron, 3wt% barium sulfate, 3wt% sodium lignosulfonate, 3wt% acetylene black are mixed uniformly to make active substance, mixed The active substance is slowly added to its total weight of 8wt% water and 12.5wt% 4.6mol / L sulfuric acid and stirred evenly to form a lead paste;

[0052] 85wt% 1960m 2 / g activated carbon material, 10wt% carbon black, and 5wt% polytetrafluoroethylene are mixed evenly in dehydrated alcohol, and the quality of dehydrated alcohol is 180 times that of the activated carbon material. The absolute ethanol was evaporated to dryness by constant stirring at 90°C to obtain a homogeneous mixture. Add 0.3ml / mg of absolute ethanol to the mixture, roll it into a tablet, and then dry it at 90°C for 12 hours to obtain a carbon sheet. The loading of the mixture in the carbon sheet is 3mg / cm 2 ;

[0053] 55wt% polystyrene, 25wt% acetylene black, 20wt% 1530m 2 / g activated carbon material was mixed with suff...

Embodiment 3

[0065] 85 lead powder, 3wt% humic acid, 3wt% 10mm long dacron, 3wt% barium sulfate, 3wt% sodium lignosulfonate, 3wt% acetylene black are mixed uniformly to make active substance, mixed The active substance is slowly added to its total weight of 8wt% water and 12.5wt% 4.6mol / L sulfuric acid and stirred evenly to form a lead paste;

[0066] 85wt% 1960m 2 / g activated carbon material, 10wt% carbon black, and 5wt% polytetrafluoroethylene are mixed evenly in dehydrated alcohol, and the quality of dehydrated alcohol is 180 times that of the activated carbon material. The absolute ethanol was evaporated to dryness by constant stirring at 90°C to obtain a homogeneous mixture. Add 0.3ml / mg of absolute ethanol to the mixture, roll it into a tablet, and then dry it at 90°C for 12 hours to obtain a carbon sheet. The loading of the mixture in the carbon sheet is 3mg / cm 2 ;

[0067] 60wt% polystyrene, 20wt% acetylene black, 20wt% 1530m 2 / g activated carbon material was mixed with suff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com