A method for co-producing bovine bone essence and collagen active peptide using bovine bone

A technology for collagen and active peptides, which is applied in the fields of protein-containing food ingredients, fermentation, food science, etc., can solve the problems of no nutritional value and low nutritional value, so as to solve the problem of insufficient nutritional value, rich nutrition, and increase enzymatic hydrolysis. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Wash the beef bone and boil it in water for 20 minutes to remove the fat, remove it and crush it with a bone crusher to obtain bone meal;

[0032] (2) irradiating the bone meal under far-infrared rays, the wavelength of the far-infrared rays is 2-14 μm, the irradiation temperature is 120° C., and the irradiation time is 20 minutes;

[0033] (3) Mix the bone meal obtained in step (2) with water at a mass ratio of 1:2, and then place it in an autoclave for hot-press extraction to obtain an extract. The conditions for hot-press extraction are pressure 0.2 MPa, temperature 150°C, extract for 0.5 hours, and then carry out high-pressure homogenization treatment at 15MPa;

[0034] (4) Carry out enzymolysis once under agitation condition after adding composite protease in step (3) gained extract, described composite protease is by pepsin, trypsin, cathepsin, papain, bromelain and neutral protease according to Mixed in the ratio of 2:2:1:1:1:1, the temperature of the enzymo...

Embodiment 2

[0039] (1) Wash the beef bone and boil it in water for 20 minutes to remove the fat, remove it and crush it with a bone crusher to obtain bone meal;

[0040] (2) irradiating the bone meal under far-infrared rays, the wavelength of the far-infrared rays is 2-14 μm, the irradiation temperature is 140° C., and the irradiation time is 15 minutes;

[0041] (3) Mix the bone meal obtained in step (2) with water at a mass ratio of 1:3, and then place it in an autoclave for hot-press extraction to obtain an extract. The conditions for hot-press extraction are pressure 0.2 MPa, temperature 130°C, extract for 2 hours, and then carry out high-pressure homogenization treatment at 12MPa;

[0042] (4) Carry out enzymolysis once under agitation condition after adding composite protease in step (3) gained extract, described composite protease is by pepsin, trypsin, cathepsin, papain, bromelain and neutral protease according to Mixed in the ratio of 2:2:1:1:1:1, the temperature of the enzymoly...

Embodiment 3

[0047] (1) Wash the beef bone and boil it in water for 15 minutes to remove the fat, remove it and crush it with a bone crusher to obtain bone meal;

[0048] (2) irradiating the bone meal under far-infrared rays, the wavelength of the far-infrared rays is 2-14 μm, the irradiation temperature is 150° C., and the irradiation time is 10 minutes;

[0049] (3) Mix the bone meal obtained in step (2) with water at a mass ratio of 1:4, and then place it in an autoclave for hot-press extraction to obtain an extract. The conditions for hot-press extraction are pressure 0.1 MPa, temperature 150°C, extract for 1 hour, and then carry out high-pressure homogenization treatment at 14MPa;

[0050] (4) Carry out enzymolysis once under agitation condition after adding composite protease in step (3) gained extract, described composite protease is by pepsin, trypsin, cathepsin, papain, bromelain and neutral protease according to Mixed in the ratio of 2:2:1:1:1:1, the temperature of the enzymolys...

PUM

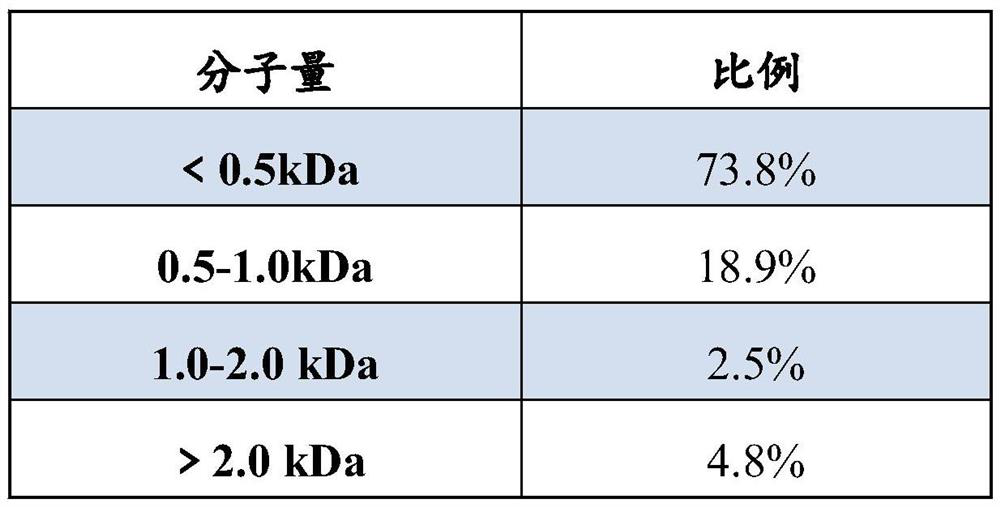

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com