Novel material capable of separating soil pollutants and preparation process thereof

A preparation process and new material technology, applied in the field of new materials that can separate soil pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

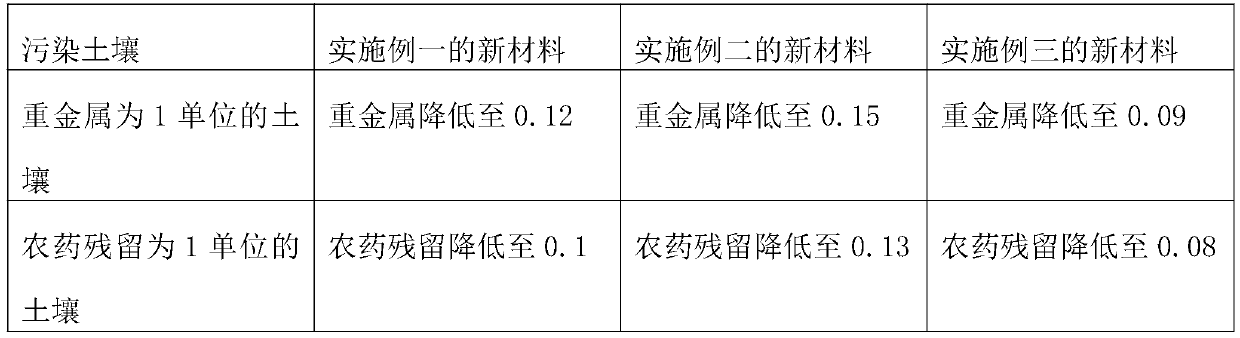

Embodiment 1

[0023] The new material capable of separating soil pollutants is made of the following raw material proportions by weight: 1 part of strong magnetic material, 10 parts of porous charcoal, and 10 parts of clay.

[0024] The preparation process of the above-mentioned new material capable of separating soil pollutants comprises the following steps:

[0025] The first step, mixing, stir and mix the strong magnetic material, porous carbon, and clay evenly to obtain a mixture:

[0026] In the second step, granulation, the mixture is granulated by a granulator, and the granulation particle size is 1mm, and granules are obtained after granulation;

[0027] The third step is drying, drying the granules by drying or drying, and the moisture content of the granules is less than 15%;

[0028] The fourth step is high-temperature oxygen-isolated firing. The particles are placed in a kiln for oxygen-isolated firing. The firing temperature is 400°C and the firing time is 5 hours. After firin...

Embodiment 2

[0033] The new material capable of separating soil pollutants is made of the following raw material proportions by weight: 12 parts of strong magnetic material, 45 parts of porous charcoal, and 62 parts of clay.

[0034] The preparation process of the above-mentioned new material capable of separating soil pollutants comprises the following steps:

[0035] The first step, mixing, stir and mix the strong magnetic material, porous carbon, and clay evenly to obtain a mixture:

[0036] In the second step, granulation, the mixture is granulated by a granulator, and the granulation particle size is 6mm, and granules are obtained after granulation;

[0037] The third step is drying, drying the granules by drying or drying, and the moisture content of the granules is less than 15%;

[0038] The fourth step is high-temperature oxygen-isolated firing. The particles are placed in a kiln for oxygen-isolated firing. The firing temperature is 800°C and the firing time is 6 hours. After fir...

Embodiment 3

[0043] The new material capable of separating soil pollutants is made of the following raw material proportions by weight: 20 parts of strong magnetic material, 70 parts of porous charcoal, and 89 parts of clay.

[0044] The preparation process of the above-mentioned new material capable of separating soil pollutants comprises the following steps:

[0045] The first step, mixing, stir and mix the strong magnetic material, porous carbon, and clay evenly to obtain a mixture:

[0046] In the second step, granulation, the mixture is granulated by a granulator, and the granulation particle size is 10mm, and granules are obtained after granulation;

[0047] The third step is drying, drying the granules by drying or drying, and the moisture content of the granules is less than 15%;

[0048] The fourth step is high-temperature oxygen-isolated firing. The particles are placed in the kiln for oxygen-isolated firing. The firing temperature is 1200°C and the firing time is 7 hours. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com