Method for inhibiting methane production by anaerobic methanogenesis mixed bacteria

An anaerobic methane production and methane production technology, applied in the field of microorganisms, can solve the problems of high cost and restriction of industrial application, and achieve the effect of long-lasting inhibition, low cost and good inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

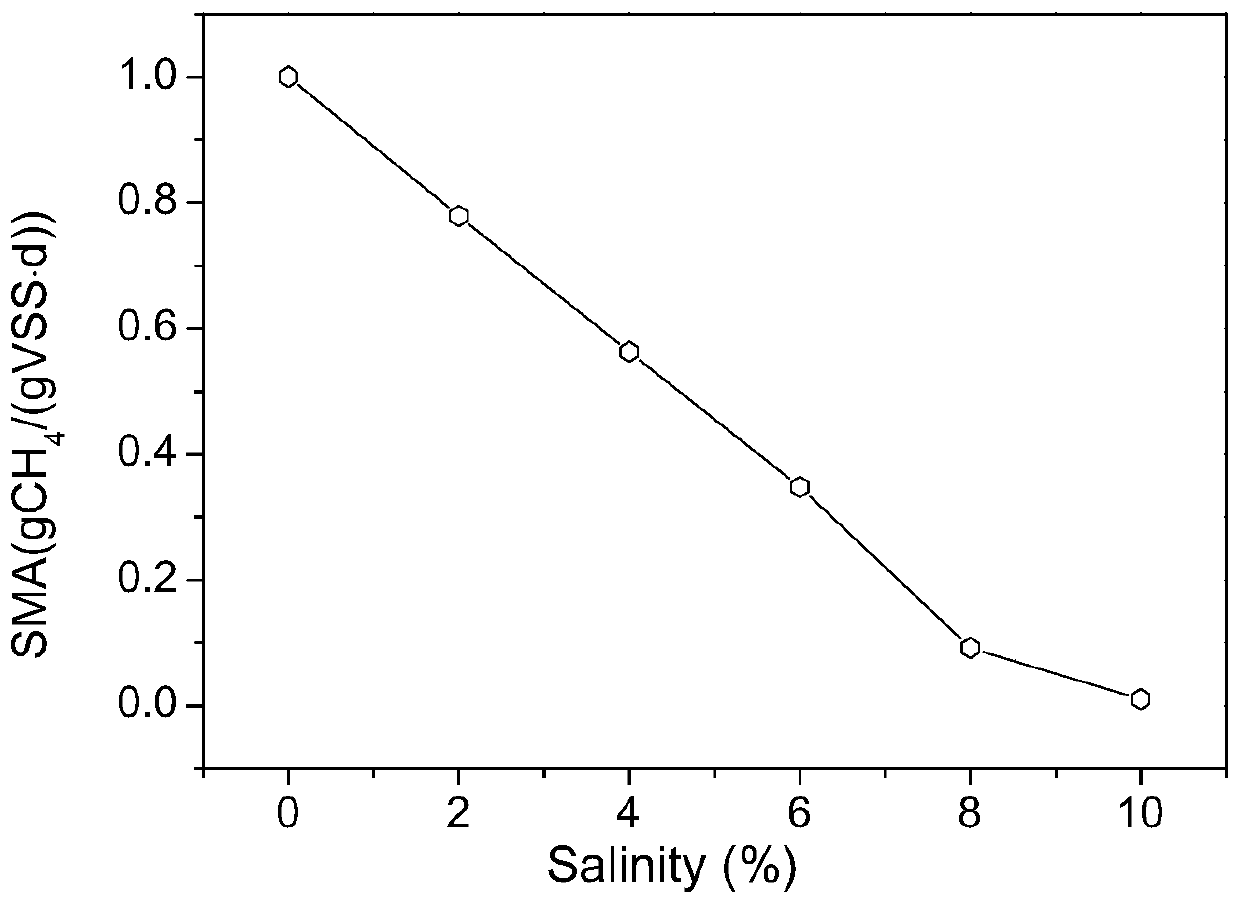

[0027] Sludge from a medium-temperature methanogenic anaerobic reactor of Shandong Huayi Corn Technology Co., Ltd. was passed through a 200-mesh iron sieve to remove non-biological impurities. Use the anaerobic inorganic salt medium to suspend the above sludge, vortex and oscillate to mix evenly, place the centrifuge at 8000rpm, centrifuge for 5 minutes, and remove the supernatant; repeat the above steps 3 times to ensure that organic matter and other interference factors are removed.

[0028] Inoculate the cleaned sludge into a 120mL serum bottle and add 20mL medium at the same time to ensure that the amount of microorganisms added is around 1-2g / L. Nitrogen gas was aerated for 15 minutes, and the above serum bottle was sealed with a butyl rubber stopper and an aluminum cap. Use a vacuum pump to remove the air from the top of the serum bottle so that the air pressure in the headspace is -0.1Mpa. 100 mL (hydrogen / carbon dioxide = 80% / 20%) mixed gas was introduced. The amount...

Embodiment 2

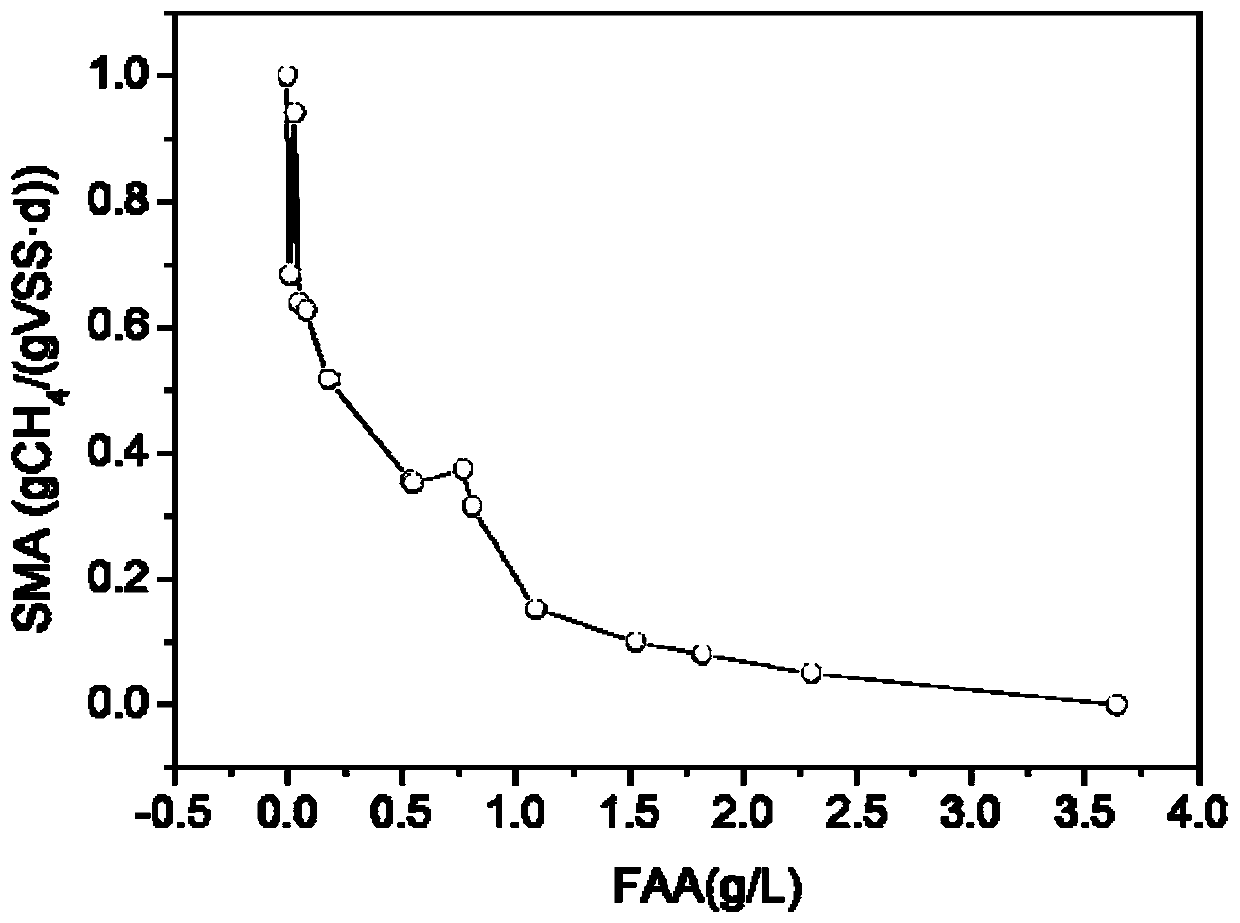

[0034] Using the same conditions as in Example 1, changing the addition of sodium chloride to free acetic acid as an inhibitor, the concentration of free acetic acid in the medium is 0g / L, 001g / L, 0.03g / L, 0.05g / L, 0.08 g / L,0.09g / L,0.16g / L,0.18g / L,0.27g / L,0.46g / L,0.54g / L,0.77g / L,0.81g / L,1.09g / L,1.53 g / L, 1.82g / L, 2.3g / L, 3.64g / L, to detect the production of methane, the experimental results are as follows figure 2 shown.

[0035] Depend on figure 2 It can be seen that as the concentration of free acetic acid increases, methane is produced less, and the concentration of free acetic acid that produces a 50% methane inhibition rate is 0.31 g / L.

Embodiment 3

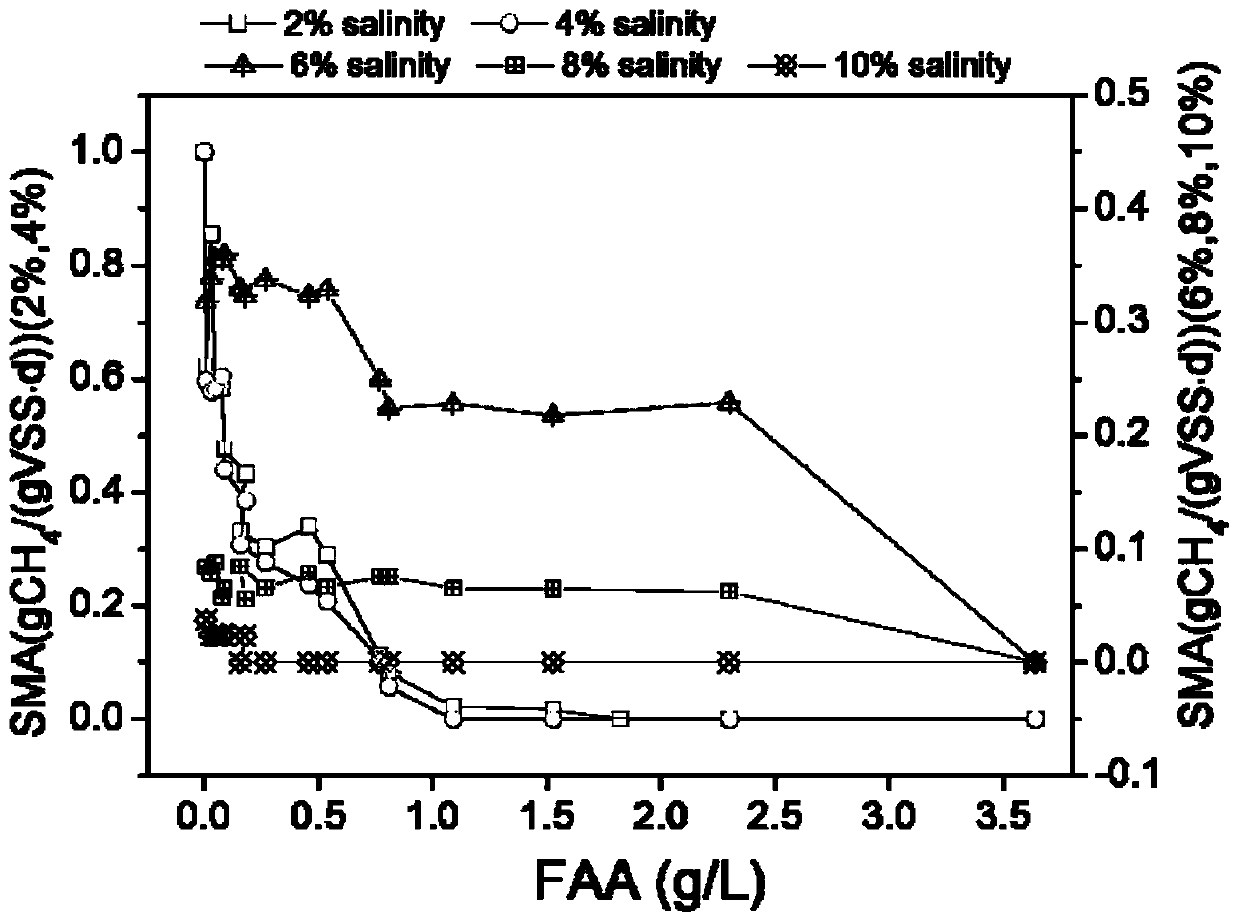

[0037] Using the same conditions as in Example 1, changing the addition of sodium chloride to add mass percentage is 0%, 2%, 4%, 6%, 8%, and the coupling concentration of sodium chloride of 10% is 0g / L, 001g / L,0.03g / L,0.05g / L,0.08g / L,0.09g / L,0.16g / L,0.18g / L,0.27g / L,0.46g / L,0.54g / L,0.77g / L L, 0.81g / L, 1.09g / L, 1.53g / L, 1.82g / L, 2.3g / L, 3.64g / L free acetic acid is used as an inhibitor to detect the production of methane. The experimental results are as follows image 3 shown.

[0038] Depend on image 3 It can be seen that sodium chloride coupled with free acetic acid can inhibit the production of methane, and 0.14g / L free acetic acid+2% sodium chloride or 0.12g / L free acetic acid+4% sodium chloride can achieve a 50% methane inhibition rate. The concentration of sodium chloride and free acetic acid used is lower than that of sodium chloride used alone, and is also lower than that of free acetic acid used alone, indicating that sodium chloride coupled with free acetic acid inh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com