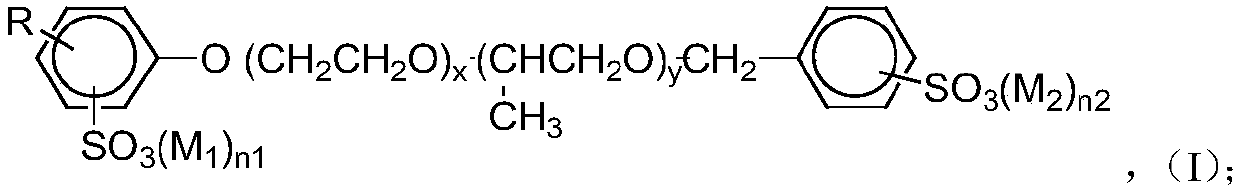

Alkyl phenol polyether diphenyl sulfonate oil displacement surfactant, composition and preparation method and application thereof

A technology of surfactant and bis-benzene sulfonate, which is applied in drilling compositions, chemical instruments and methods, chemical recovery and other directions, can solve the problems of high oil displacement efficiency and low oil displacement efficiency, and achieve improved recovery. rate, the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Surfactant Preparation

[0048] a) Add 1 mol of octylphenol and 0.1 mol of sodium hydroxide to a reactor equipped with a condensing device, a stirring device and a gas disperser, and heat to 85°C while blowing nitrogen, and then stir for 1 hour. Turn on the vacuum system, vacuumize and dehydrate for 1 hour at a temperature of 90°C, then purge 4 times with nitrogen to remove the air in the system, then adjust the reaction temperature of the system to 150°C and slowly introduce 2mol ethylene oxide to control The ethoxylation reaction is carried out at a pressure of ≤0.40MPa; after the reaction is completed, the system is purged with nitrogen, neutralized and dehydrated after cooling to obtain 0.98mol of octylphenol polyoxyethylene (2) ether.

[0049] b) Add 0.98 mol of octylphenol polyoxyethylene (2) ether obtained in step a) into a reactor equipped with a stirring device and a condensation reflux device, add 0.98 mol of benzyl chloride and 0.05 mol of copper chloride,...

Embodiment 2

[0059] 1. Surfactant Preparation

[0060] a) Add 1 mol of nonylphenol and 0.1 mol of sodium hydroxide into a reactor equipped with a condensing device, a stirring device and a gas disperser, and heat to 85°C while blowing nitrogen, then stir for 1 hour. Turn on the vacuum system, vacuumize and dehydrate for 1 hour at a temperature of 90°C, then purge 4 times with nitrogen to remove the air in the system, then adjust the reaction temperature of the system to 150°C, and slowly introduce 2mol ethylene oxide in sequence and 2mol propylene oxide, control the pressure ≤ 0.40MPa to carry out ethoxylation reaction; after the reaction, purging the system with nitrogen, neutralize and dehydrate after cooling, to obtain 0.94mol nonylphenol polyoxyethylene (2) polyoxypropylene (2) Ether.

[0061] b) Add 0.94mol of nonylphenol polyoxyethylene (2) polyoxypropylene (2) ether obtained in step a) into a reactor equipped with a stirring device and a condensation reflux device, add 0.94mol of b...

Embodiment 3

[0066] 1. Surfactant Preparation

[0067] a) Add 1 mol of dodecylphenol and 0.1 mol of sodium hydroxide into a reactor equipped with a condensing device, a stirring device and a gas disperser, and heat to 85° C. while blowing nitrogen, and react with stirring for 1 hour. Turn on the vacuum system, vacuumize and dehydrate for 1 hour at a temperature of 90°C, then use nitrogen to blow 4 times to remove the air in the system, then adjust the reaction temperature of the system to 150°C and slowly introduce 4mol ethylene oxide to control The ethoxylation reaction is carried out at a pressure of ≤0.40MPa; after the reaction is completed, the system is purged with nitrogen, neutralized and dehydrated after cooling to obtain 0.95mol of dodecylphenol polyoxyethylene (4) ether.

[0068] b) 0.95mol dodecylphenol polyoxyethylene (4) ether obtained in step a) is added to a reactor equipped with a stirring device and a condensation reflux device, 0.95mol benzyl chloride and 0.05mol copper c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com