Entrained-flow bed gasification furnace and gasification method of carbonaceous raw material

A technology of gasification furnace and entrained bed, applied in the direction of gasification device feeding tool, gasification process, gasification device details, etc., can solve the problems of low carbon conversion rate, high energy consumption, poor environmental protection, etc., and achieve improved thermal efficiency , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Using coal A as the third carbonaceous raw material, the analysis results of the coal A sample are shown in Table 1. Coal A is pyrolyzed using a solid heat carrier pyrolysis furnace, and the semi-coke produced by pyrolysis at 600°C is used as the first carbonaceous raw material, and its particle size ranges from 0.1 to 0.45mm. The analysis results of the first carbonaceous raw material As shown in table 2. Coal A is dried and crushed to obtain a second carbonaceous raw material whose particle size is less than or equal to 0.15mm.

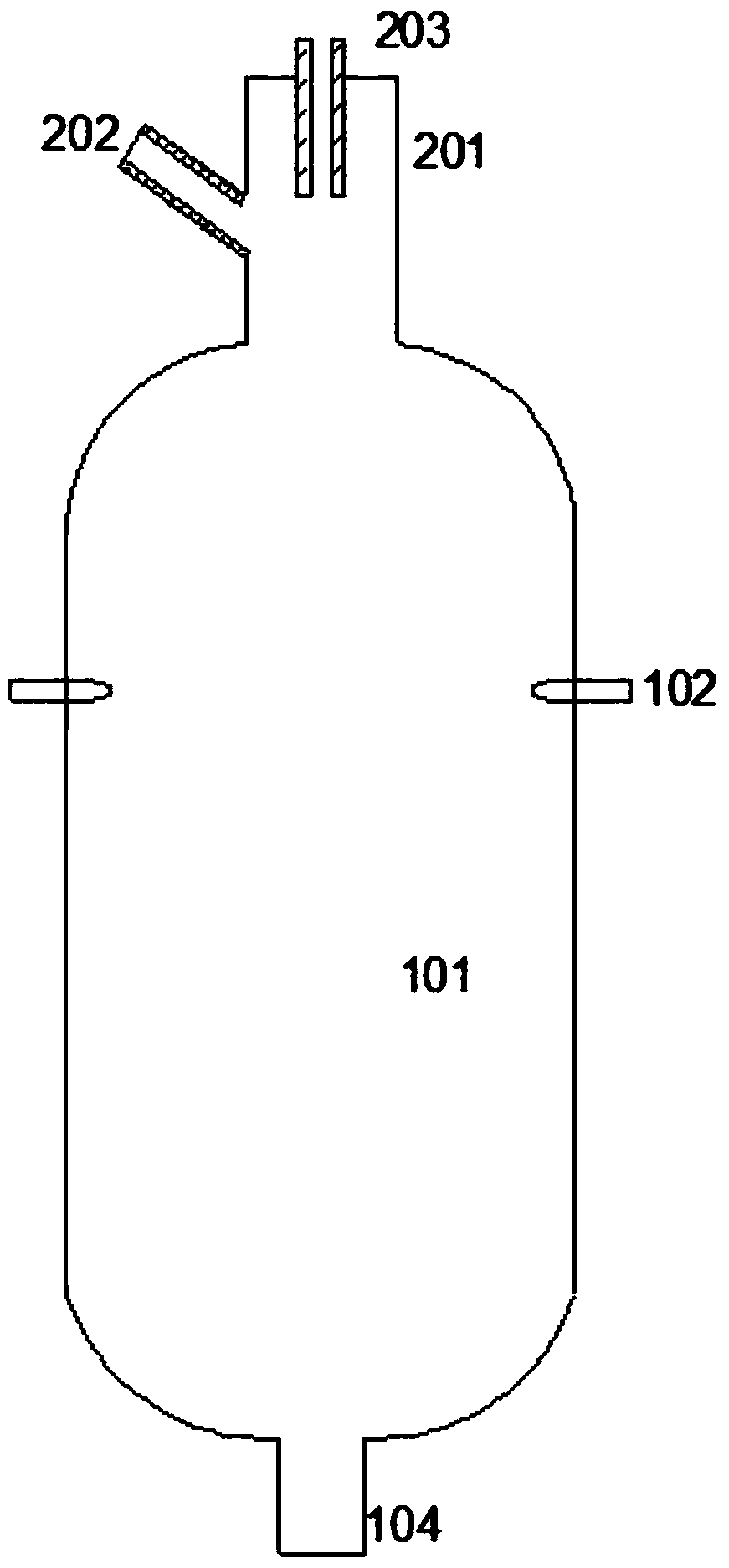

[0046] The entrained-bed gasifier provided by the present invention comprises a first feeding system, a second feeding system, a vertical furnace body and a slag outlet. Among them, the first feeding system includes a feeding cylinder, a main feeding pipe and an auxiliary feeding pipe, the inner diameter ratio of the feeding cylinder and the vertical furnace body is 0.3:1, and the ratio of the feeding cylinder to the vertical furnace body T...

Embodiment 2

[0061] Coal A is also used as the third carbonaceous raw material. Coal A is partially gasified using a fluidized bed gasifier, and the gasification residue, that is, carbon-containing by-products, is used as the first carbonaceous raw material, and its particle size ranges from 0.1 to 0.45mm. The analysis results of the first carbonaceous raw material As shown in Table 4. Coal A is dried and crushed to obtain a second carbonaceous raw material whose particle size is less than or equal to 0.15mm.

[0062] The gasification reaction was carried out using the same entrained bed gasifier as in Example 1.

[0063] The feed temperature of the first carbonaceous raw material is 850°C, and enters the feed cylinder through the main feed pipe, and then enters the vertical furnace body. The feed temperature of the second carbonaceous raw material is 40°C, and enters the vertical furnace body from the burner. The mass ratio of the first carbonaceous raw material to the second carbonace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com