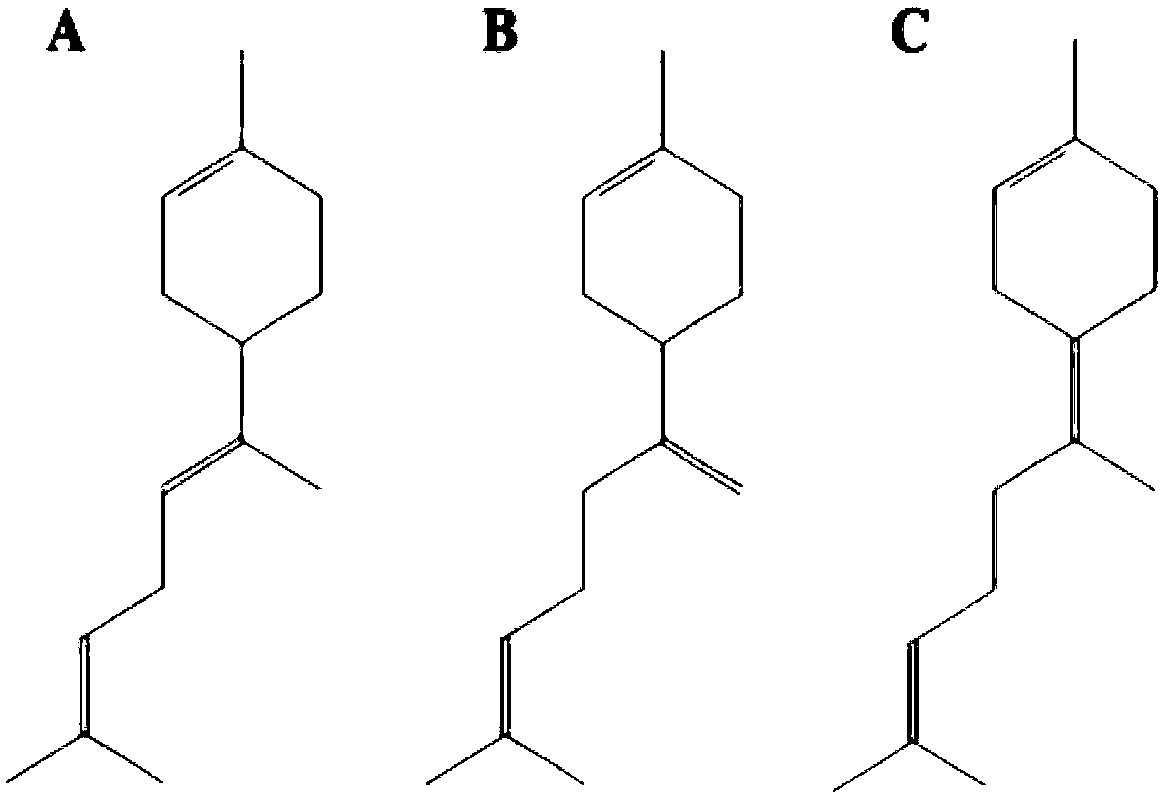

Yarrowia lipolytica capable of producing bisabolene and constructing method for yarrowia lipolytica and use of yarrowia lipolytica

A technology of Yarrowia lipolytica and bisabolene, applied in the field of molecular biology, can solve the problem of low yield of bisabolene heterologous synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

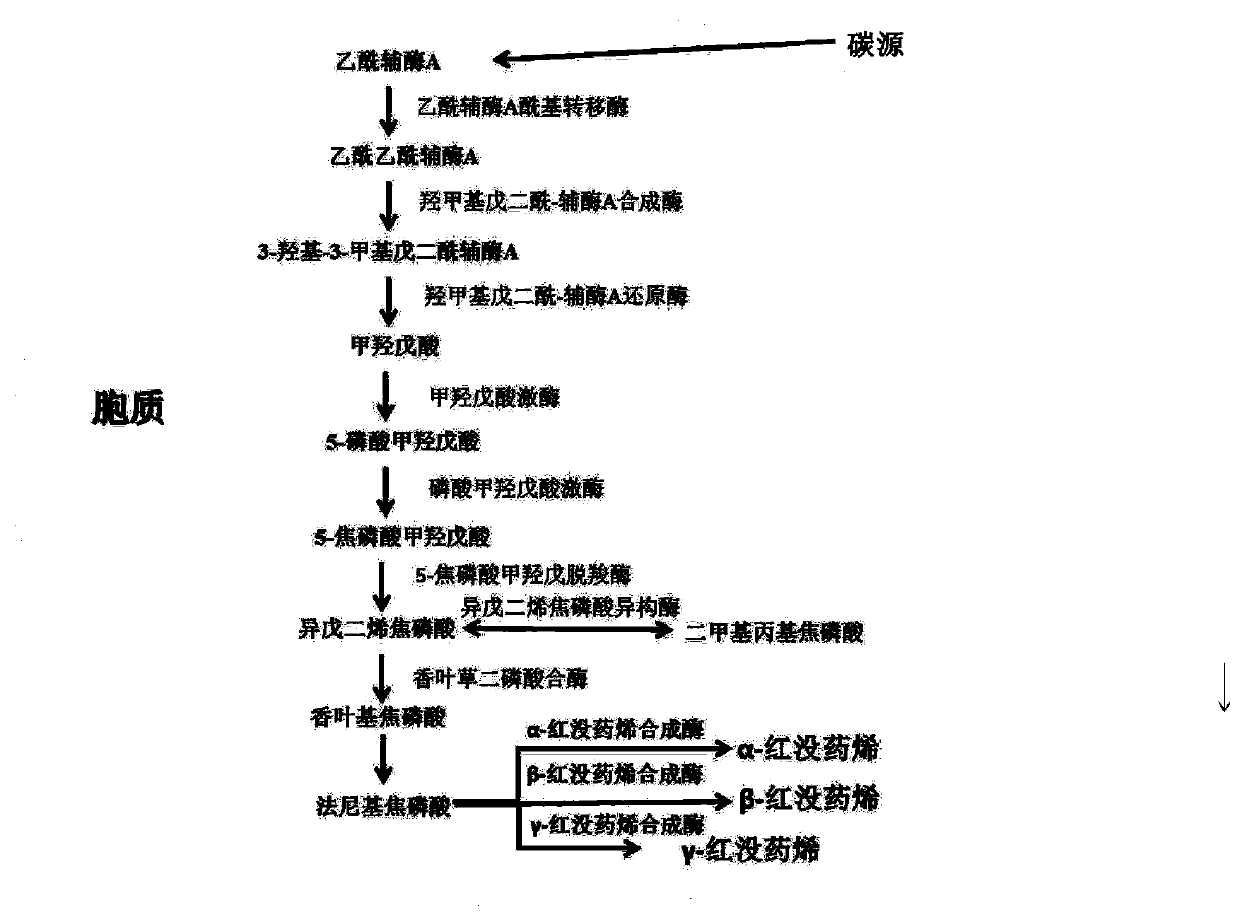

[0076] Example 1: Construction of a Yarrowia lipolytica strain producing bisabolene

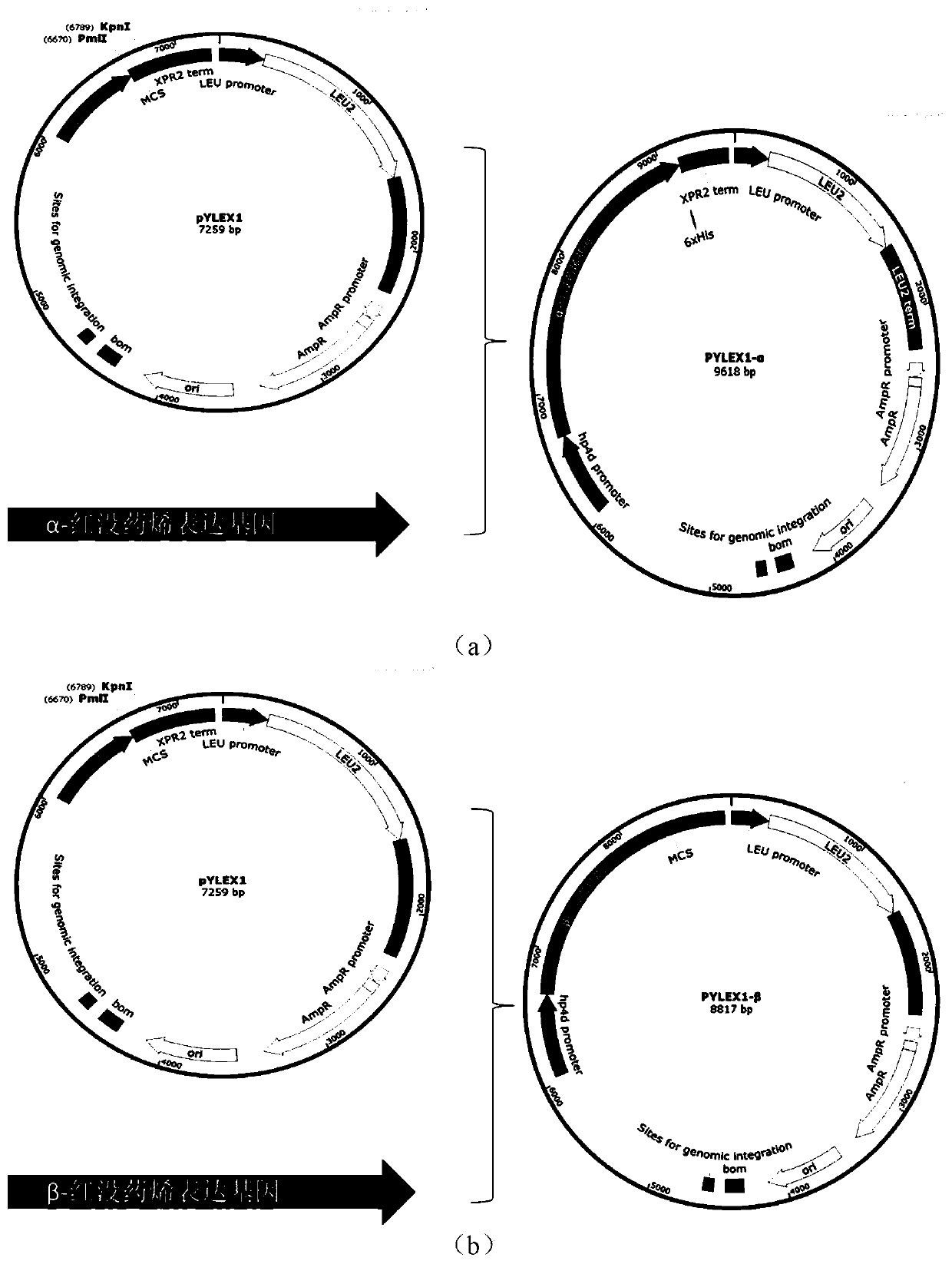

[0077] According to the nucleotide sequence of α-bisabolene synthase gene, nucleotide sequence of β-bisabolene synthase gene and nucleotide sequence of γ-bisabolene synthase gene in Genebank, lipolysis Saccharomyces pylori codon usage preference was respectively optimized for codons and a His tag was added to the 3' end of the gene, and then synthesized by a gene synthesis company. The nucleotide sequence of the synthesized α-bisabolene synthase gene is shown in the sequence listing as SEQ ID Shown in NO: 1; the nucleotide sequence of the synthetic β-bisabolene synthase gene is shown in SEQ ID NO: 2 in the sequence listing; the nucleotide sequence of the synthetic γ-bisabolene synthase gene is shown in sequence Shown in SEQID NO: 3 in the list. According to the gene sequence after synthesis, the HMGR reference sequence and the integrated plasmid sequence in Genebank, each primer (shown in Ta...

Embodiment 2

[0090] Example 2: Comparison of Bisabolene Fermentation Production by Genetic Engineering Bacteria

[0091] (1) Experimental method

[0092] Take one loop of the engineering bacteria and the starting strain Yarrowia lipolytica Po1gΔku70, inoculate in a 250mL Erlenmeyer flask containing 25mL YPD medium, 30°C, 225r / min, vibrate for 24 hours, inoculate with 1% inoculum in a 25mL Erlenmeyer flask containing In a 250mL Erlenmeyer flask of YPD medium, 30°C, 225r / min, continue shaking culture for 16h, then inoculate into a 250mL Erlenmeyer flask containing 50mL of YPD medium at an inoculum size of 1%, and add 10% Twelve alkanes, 28°C, 225r / min, shake flask fermentation for 5 days.

[0093] Composition of YPD medium: peptone 20g / L, yeast extract powder 10g / L, glucose 20g / L, the balance is water, pH5.7-5.8, 115°C, sterilized for 20min.

[0094] After the fermentation, all the fermentation broth was poured into a 50mL centrifuge tube, centrifuged at 7500rpm, 4°C for 5min, the organic ...

Embodiment 3

[0114] Example 3: Fermentative production of bisabolene by genetically engineered bacteria using an optimized cheap carbon source

[0115] The engineering bacteria Po1gΔku70α-HR, Po1gΔku70β-HR and Po1gΔku70γ-HR obtained in Example 1 and the starting strain Po1gΔku70 of Yarrowia lipolytica get a circle, inoculate in the YPD medium that contains 25mL, according to the above-mentioned embodiment 2 (1) Fermentation culture according to the fermentation method, 30°C, 225r / min, shaking culture for 24h, inoculate 1% inoculum in a 250mL Erlenmeyer flask containing 25mL YPD medium, 30°C, 225r / min, continue shaking culture for 16h Inoculate 1% of the inoculum into a 250mL Erlenmeyer flask containing 50mL of optimized cheap medium, add 10% dodecane, 28°C, 225r / min, and shake the flask for 5 days of fermentation.

[0116] The composition of the cheap optimized medium is: peptone 20g / L, yeast extract powder 10g / L, kitchen waste oil 11.8mL / L, magnesium sulfate 2g / L, the balance is water, pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com