A low-melting-point nylon hot-melt yarn for preparing fly-woven shoe uppers

A low-melting-point, hot-melt yarn technology, which is applied in rayon manufacturing, final product manufacturing, textiles and papermaking, etc., can solve the problems of complex process, high melting point, and high cost of fly-woven shoe uppers, and achieve simple process and improve polymerization quality , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

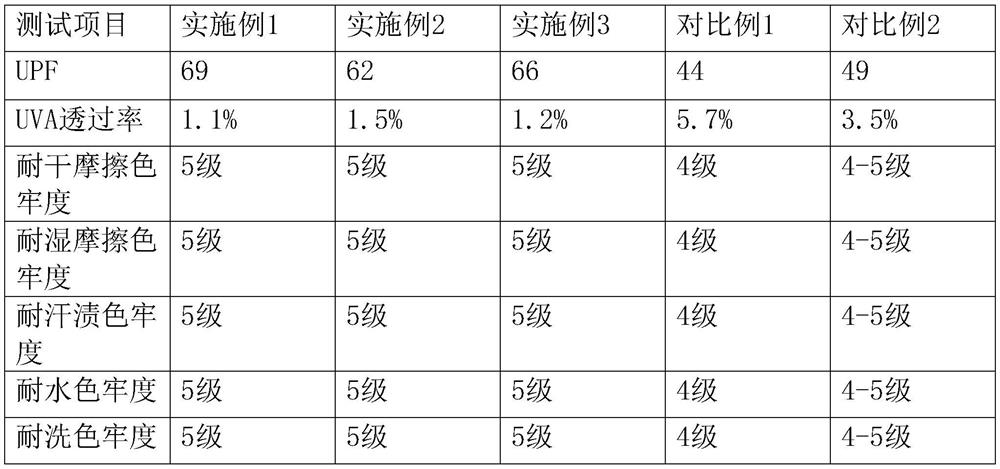

Examples

Embodiment 1

[0039] A low-melting-point nylon hot-melt yarn for preparing flying woven shoe uppers, comprising the following components by weight:

[0040] 100 parts of polyamine;

[0041] 100 parts of polybasic acid;

[0042] 2 parts catalyst;

[0043] 15 parts of modifier;

[0044] 12 parts of pigment;

[0045] 8 parts of defoamer;

[0046] 5 parts of dispersant;

[0047] Anti-aging agent 4 parts;

[0048] 3 parts of stabilizer;

[0049] The polyamine is a mixture of decanediamine, pentaethylenehexamine and (1R,2R)-(-)-N-(p-toluenesulfonyl)-1,2-diphenylethylenediamine, and its mass The ratio is 4:2:1;

[0050] The polybasic acid is a mixture of sebacic acid, terephthalic acid and dodecenylsuccinic acid, and its mass ratio is 2:1:1.

[0051] The catalyst is a mixture of bis(pentamethylcyclopentadiene) zirconium dichloride and N,N-dimethylanilinium tetrakis(pentafluorophenyl)borate, and its mass ratio is 1:1.

[0052] The modifier is 3,5-diamino-1,2,4-triazole, bicyclo(2.2.2)oct-5-...

Embodiment 2

[0067] A low-melting-point nylon hot-melt yarn for preparing flying woven shoe uppers, comprising the following components by weight:

[0068] 110 parts of polyamine;

[0069] 90 parts of polybasic acid;

[0070] 2 parts catalyst;

[0071] 15 parts of modifier;

[0072] 12 parts of pigment;

[0073] 8 parts of defoamer;

[0074] 5 parts of dispersant;

[0075] Anti-aging agent 4 parts;

[0076] 3 parts of stabilizer;

[0077] The polyamine is a mixture of decanediamine, pentaethylenehexamine and (1R,2R)-(-)-N-(p-toluenesulfonyl)-1,2-diphenylethylenediamine, and its mass The ratio is 4:2:1;

[0078] The polybasic acid is a mixture of sebacic acid, terephthalic acid and dodecenylsuccinic acid, and its mass ratio is 2:1:1.

[0079] The catalyst is a mixture of bis(pentamethylcyclopentadiene) zirconium dichloride and N,N-dimethylanilinium tetrakis(pentafluorophenyl)borate, and its mass ratio is 1:1.

[0080] The modifier is 3,5-diamino-1,2,4-triazole, bicyclo(2.2.2)oct-5...

Embodiment 3

[0095] A low-melting-point nylon hot-melt yarn for preparing flying woven shoe uppers, comprising the following components by weight:

[0096] 90 parts of polyamine;

[0097] 110 parts of polybasic acid;

[0098] 2 parts catalyst;

[0099] 15 parts of modifier;

[0100] 12 parts of pigment;

[0101] 8 parts of defoamer;

[0102] 5 parts of dispersant;

[0103] Anti-aging agent 4 parts;

[0104] 3 parts of stabilizer;

[0105] The polyamine is a mixture of decanediamine, pentaethylenehexamine and (1R,2R)-(-)-N-(p-toluenesulfonyl)-1,2-diphenylethylenediamine, and its mass The ratio is 4:2:1;

[0106] The polybasic acid is a mixture of sebacic acid, terephthalic acid and dodecenylsuccinic acid, and its mass ratio is 2:1:1.

[0107] The catalyst is a mixture of bis(pentamethylcyclopentadiene) zirconium dichloride and N,N-dimethylanilinium tetrakis(pentafluorophenyl)borate, and its mass ratio is 1:1.

[0108]The modifier is 3,5-diamino-1,2,4-triazole, bicyclo(2.2.2)oct-5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com