In-situ detection system for straight section distribution of petroleum hydrocarbon contaminants at contaminated sites

A vertical profile and in-situ detection technology, applied in the electromechanical field, can solve the problems of in-situ detection of petroleum hydrocarbons on site, cumbersome steps, secondary pollution, etc., and achieve high-efficiency detection technology and equipment for vertical profile distribution of petroleum hydrocarbon pollution on site , Improve detection efficiency, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

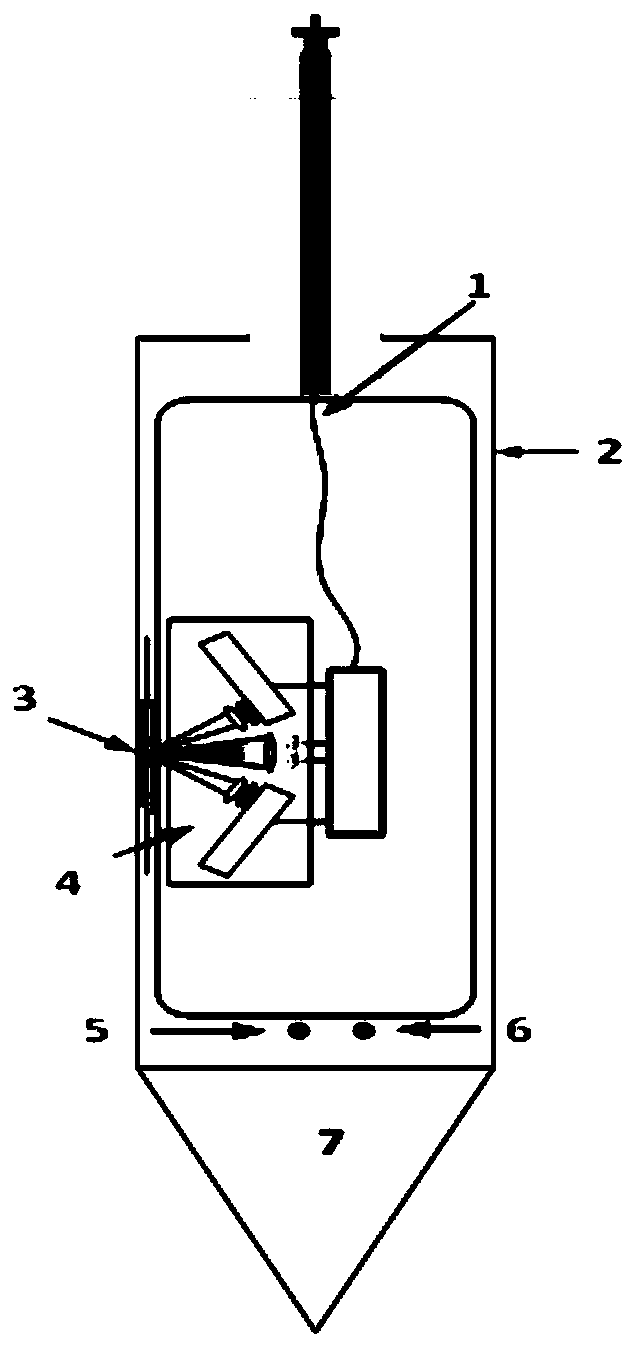

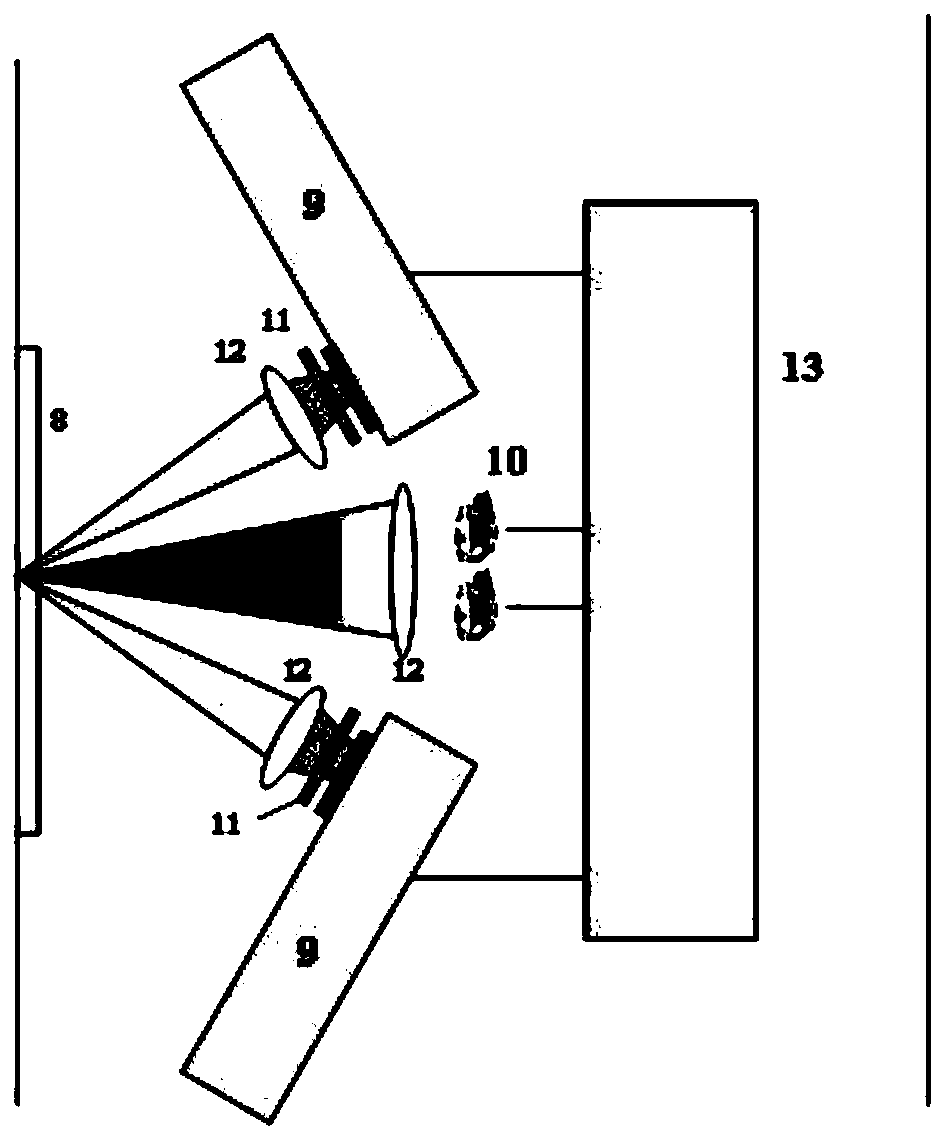

[0012] Such as Figure 1-2 As shown, an in-situ detection system for the vertical profile distribution of petroleum hydrocarbon pollutants in a polluted site of the present invention includes a casing 2, a fluorescence excitation and detection module 4, a drill bit 7, a detection window 3, and a conductivity sensor 6.

[0013] The casing 2 and the drill bit 7 constitute the casing of the in-situ detection system for the vertical profile distribution of petroleum hydrocarbon pollutants in the polluted site, wherein the drill bit 7 is mainly used for drilling the ground and carrying the system into soil layers of different depths, and the casing 2 is mainly used for the inside of the system Device protection. The detection window 3 is on the casing 2, and its main body is made of quartz glass in order to ensure the sensitivity and accuracy of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com