Automobile drive axle vibration simulation analysis method

A technology of simulation analysis and drive axle, which is applied in the field of vehicle transmission system and NVH, can solve the problems of limited space for parameter change optimization, long processing cycle, large amount of data, etc., to improve NVH performance, improve comfort, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0049] The present invention will be described in detail below with reference to the accompanying drawings and examples.

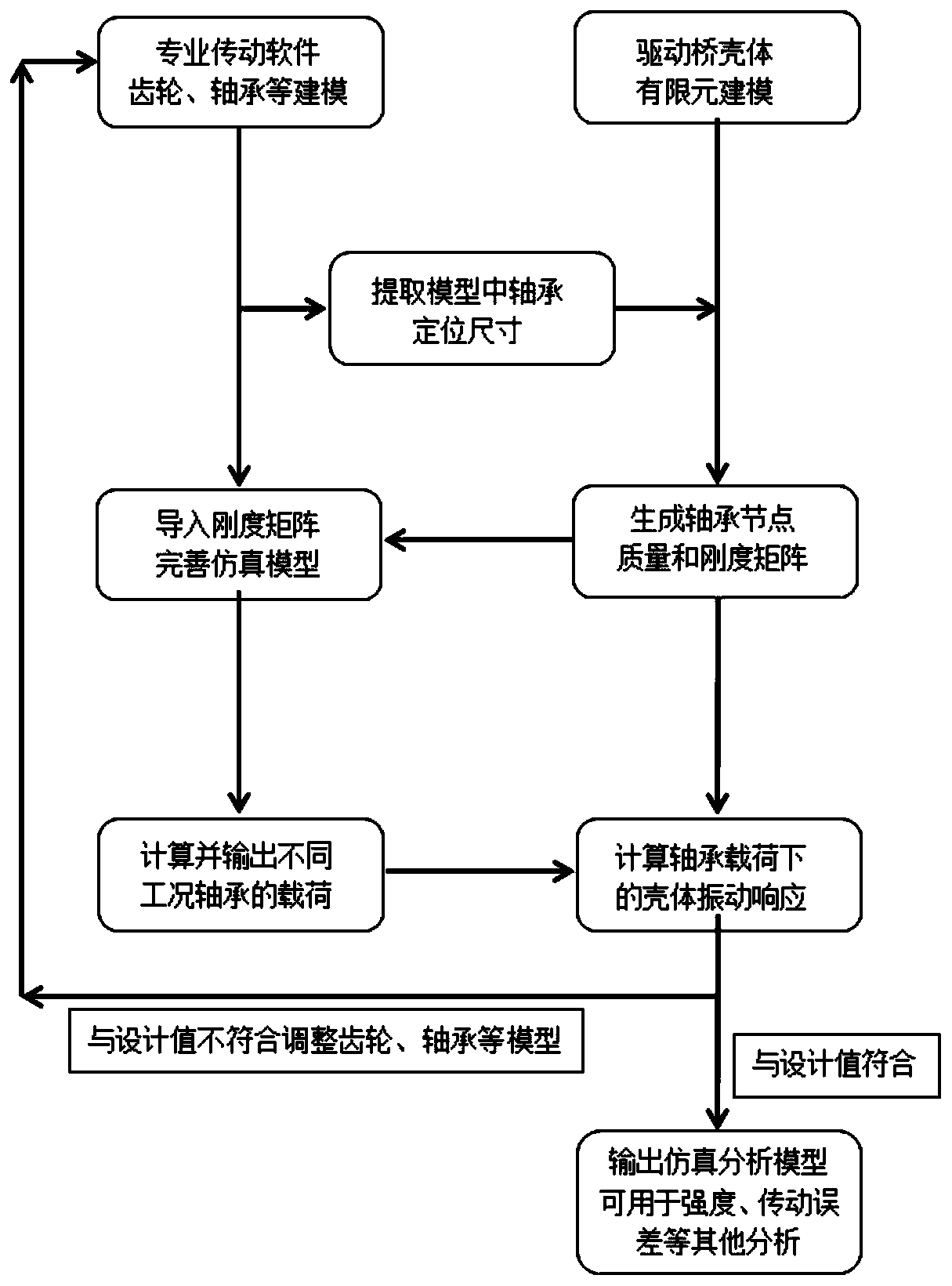

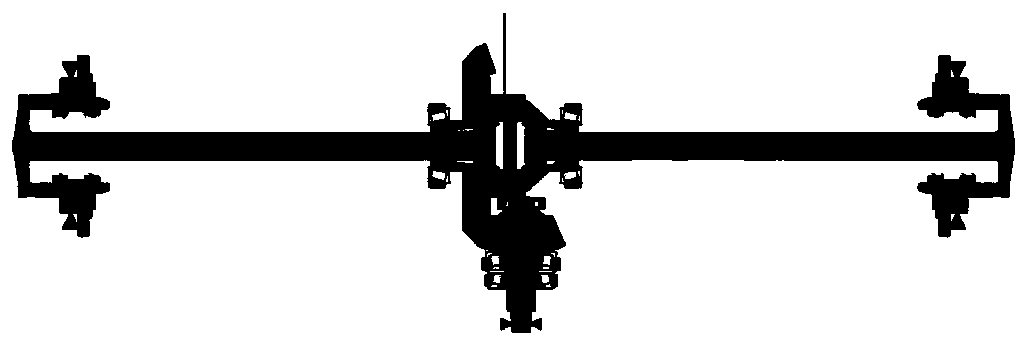

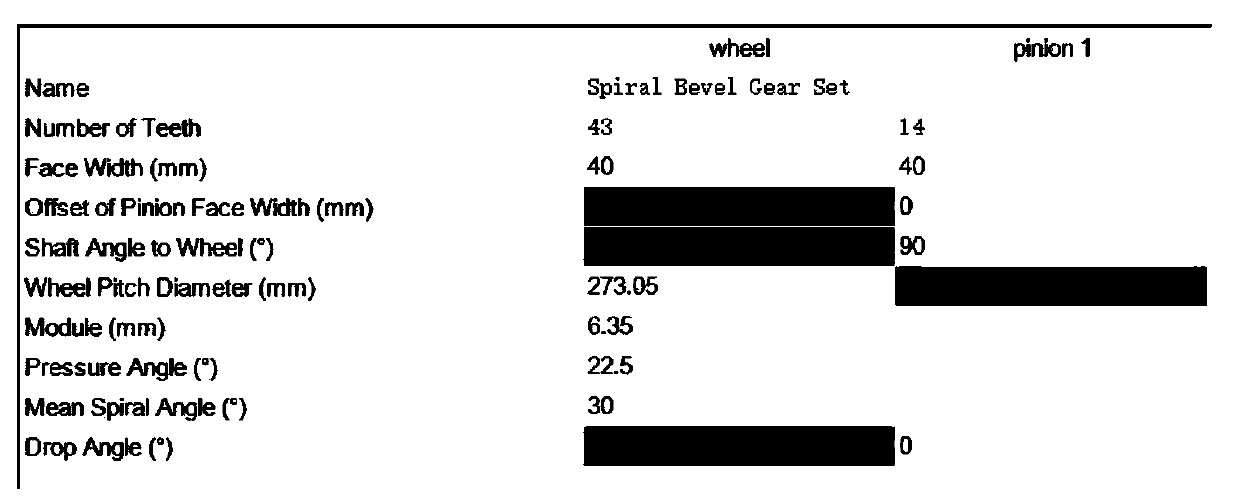

[0050] The present invention uses the method of combining finite element simulation technology and special-purpose transmission analysis software to establish the finite element model of the automobile drive axle housing, and derives the stiffness and mass matrix of the bearing nodes of the reducer. Bearings, gears, splines, half shafts and differentials are modeled, and the stiffness and mass matrices exported from the finite element model are imported into them to calculate the dynamic displacement loads of the bearing nodes under each working condition, and bring this load back into the finite element model. The dynamic response analysis is carried out in the meta-model, and the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com