Novel processing technology for root canal file and root canal file

A processing technology and root canal file technology, which is applied in the fields of adding protective layer, medical science, dentistry, etc., can solve the problems of reducing the utilization rate of expensive materials, reducing the production cost of root canal files, and poor welding performance of nickel-titanium alloys. The effect of improving welding reliability, continuous processing and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

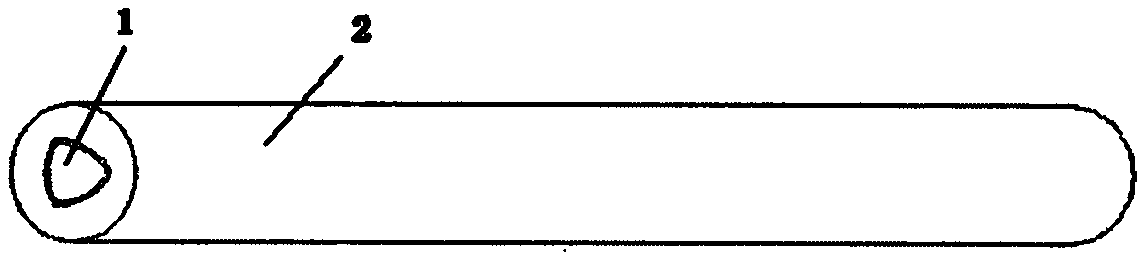

[0065] The novel root canal file processing technology of the present invention mainly includes two parts: making a composite embryo body and material reduction processing. The composite body includes a metal tube 1 and one or more metal rods 2, the metal rod 2 is drawn in the metal tube 1 and drawn synchronously with the metal tube 1, and the metal tube 1 forms a dense package outside the metal rod 2.

[0066] The steps for making a composite embryo body include:

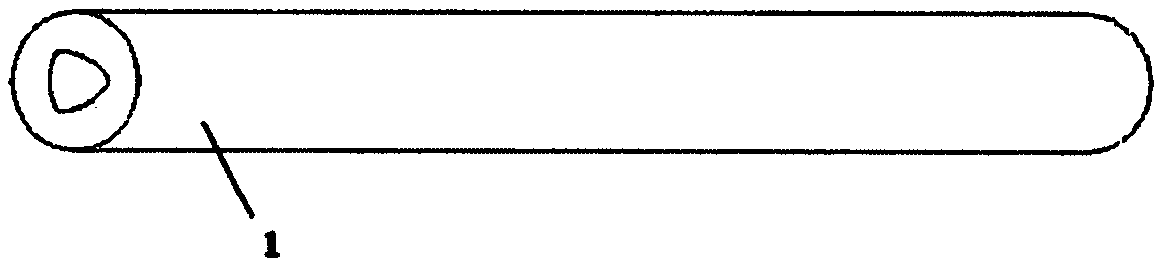

[0067] S1 as figure 1 As shown, the central part of a metal rod is processed into a metal tube 1 with a hollow structure through tools such as an electric spark punching machine, a wire electric discharge machine, and an electric spark forming machine tool; the material of the metal tube 1 can be nickel-titanium alloy, Stainless steel, cobalt-chromium alloy, copper, etc.; the material of the metal rod 2 can be nickel-titanium alloy, stainless steel, cobalt-chromium alloy, copper, etc.;

[0068] S2 as figure 2 A...

Embodiment 2

[0081] The difference between this embodiment and Embodiment 1 is that when the file body 4 is processed by mechanical twisting, the material reduction process is as follows:

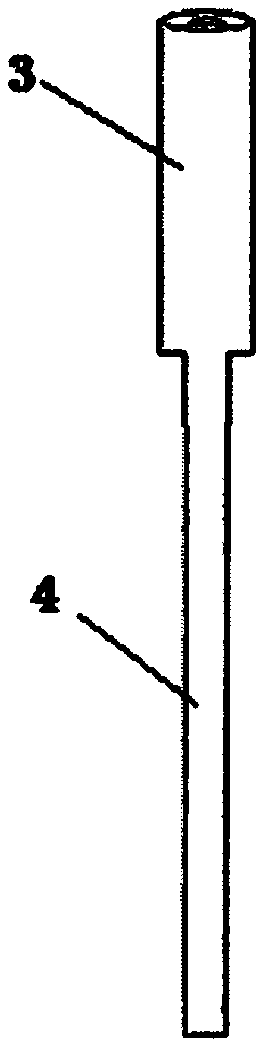

[0082] T1' as Figure 17 As shown, the composite embryo body twice the length of the root canal file is intercepted, and then centered on the midpoint of the composite embryo body, the two sides are symmetrically divided into three parts: the handle 3, the file body 4 and the connecting rod 5, and the two sides The 4 parts of the compound embryo body file body are connected at the midpoint; the outer metal tube 1 of the file body 4 is removed by grinding or chemical methods to expose the inner metal rod 2; the outer metal tube of the connecting rod 5 is partially removed 1. Make the thickness of the metal tube 1 attached to the outside of the connecting rod 5 be 0.05-0.4mm;

[0083] T2' as Figure 18 As shown, the first twisting end 8 and the second twisting end 9 are respectively located in the middl...

Embodiment 3

[0089]The main difference between this embodiment and Embodiment 1 is that the root canal file is not integrally formed. That is, in the process of subtractive machining:

[0090] T1" as Figure 22 As shown, the composite embryo body that is slightly larger than the length of the file body 4+connecting rod 5 is intercepted, and then the composite vertebral body is divided into two parts: the file body 4 and the connecting rod 5; the metal tube 1 of the outer layer of the connecting rod 5 is partially removed to make the connection The metal tube 1 attached to the outside of the rod 5 has a thickness of 0.05-0.4 mm; the outer metal tube 1 of the file body 4 is removed by grinding or chemical methods, and the inner metal rod 2 is exposed;

[0091] T2" as Figure 23 As shown, by grinding or mechanical screwing, the metal rod 2 after removing the outer metal tube 1 is made into a file body 4 with threads on the surface;

[0092] T3" as Figure 24 As shown, the handle 3 is proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com