Liquid organic fertilizer preparation method capable of avoiding stink generation

An organic fertilizer and liquid technology, which is applied in the field of liquid organic fertilizer preparation to avoid odor generation, can solve the problems of hydrogen sulfide and other problems, and achieve the effects of reducing hydrogen sulfide generation, reducing odor, and avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

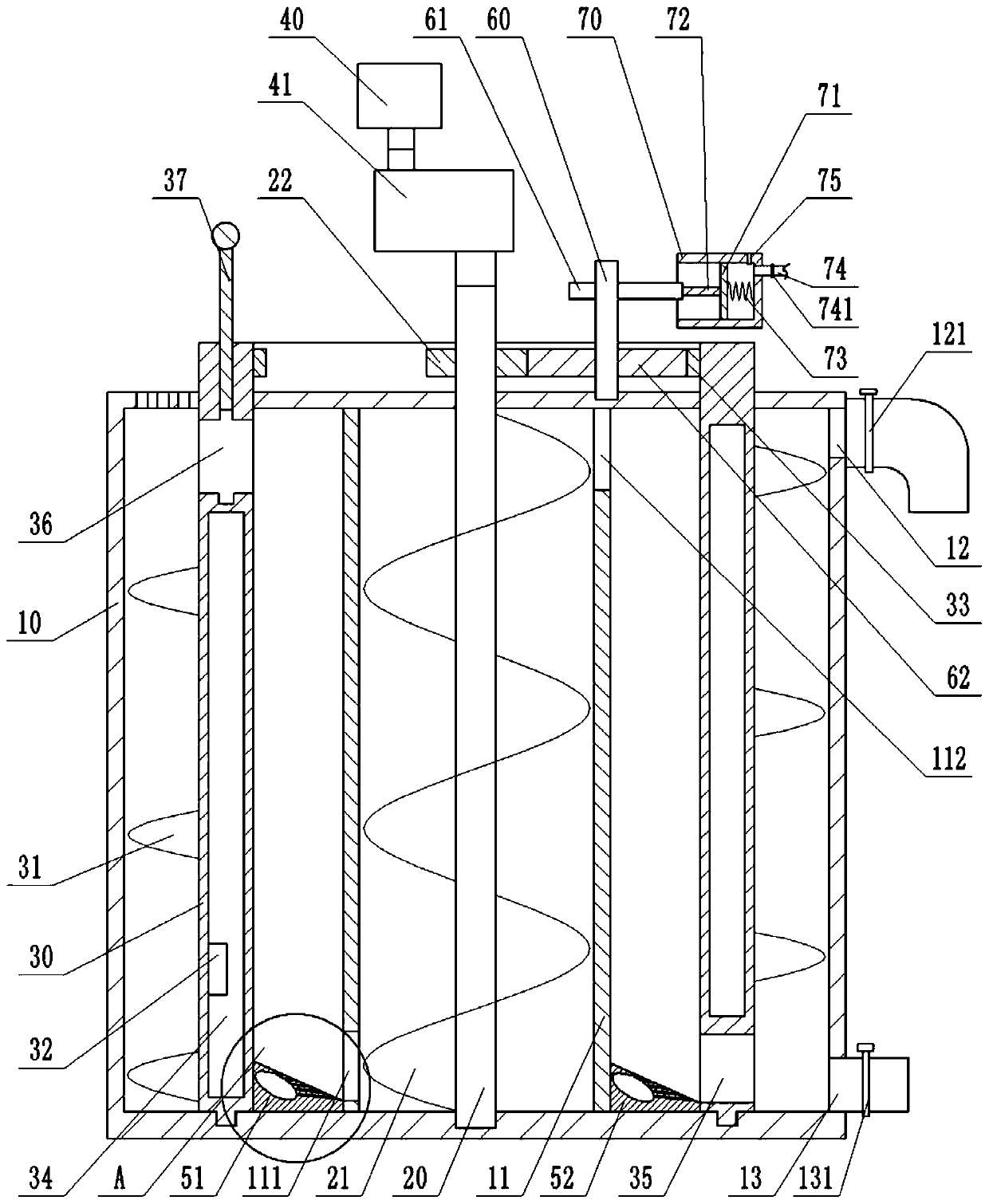

Image

Examples

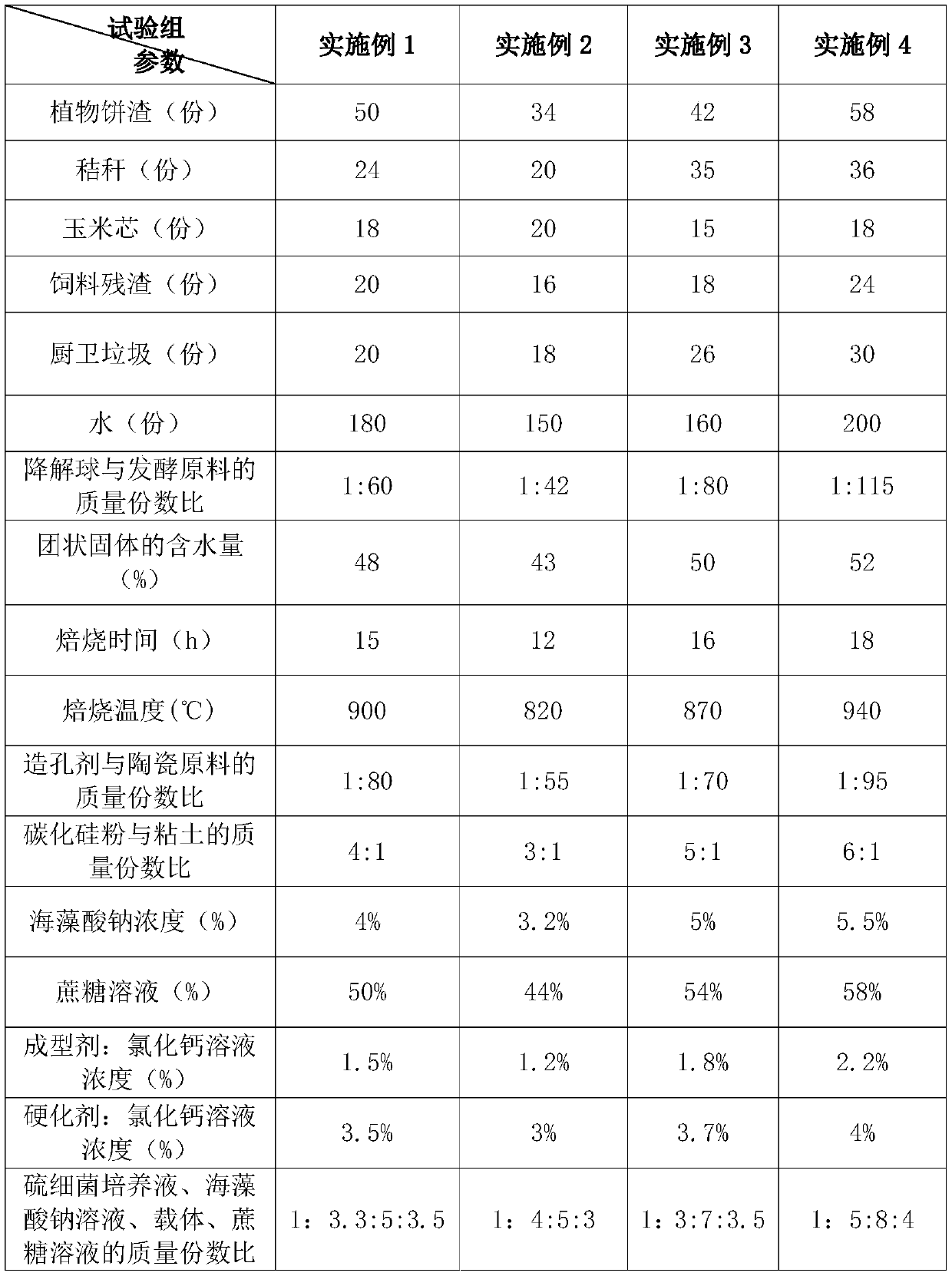

Embodiment 1

[0033] The liquid organic fertilizer preparation method that avoids odor generation comprises the following processing steps:

[0034] (1) Isolation of sulfur bacteria: Separation of sulfur bacteria capable of degrading hydrogen sulfide from poultry feces, domestication and cultivation, to obtain sulfur bacteria culture solution.

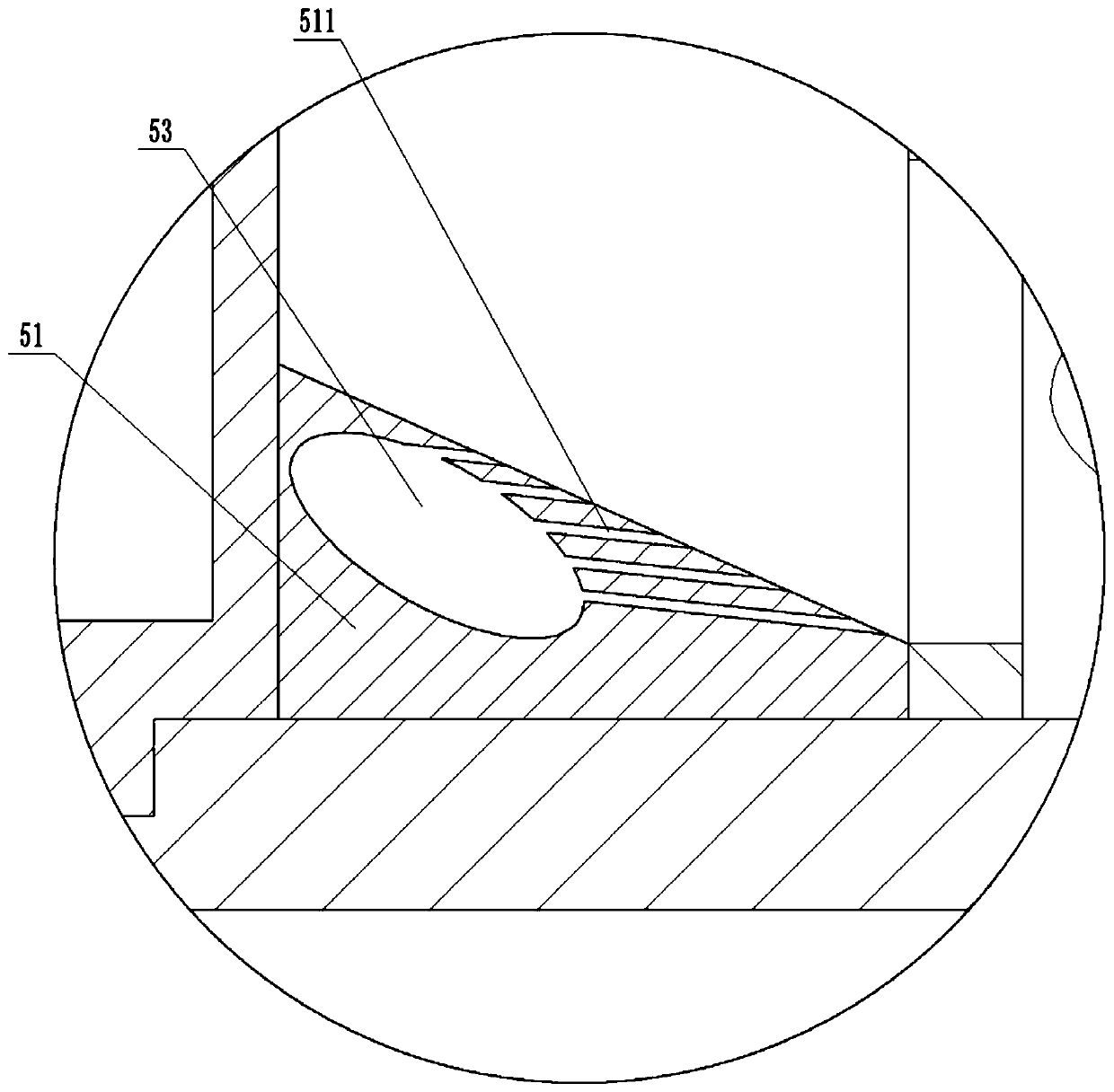

[0035](2) Preparation of degradable spheres: fix the sulfur bacteria cultured in step (1) to obtain degradable spheres, which are rich in three-dimensional channels inside the degradable spheres; the specific fixation steps are as follows:

[0036] a. Uniformly mix the ceramic raw material, pore-forming agent and water to form a lumpy solid, the water content of which is controlled at 48%; roast the lumpy solid for 15 hours at a firing temperature of 900°C; the pore-forming agent and the ceramic raw material The mass-to-number ratio is 1:80. Among them, the ceramic raw materials include silicon carbide powder and clay, and the mass-number ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com