Ultraviolet light-cured water-based gravure ink and preparation method thereof

A gravure printing ink, light curing technology, applied in the direction of ink, household appliances, applications, etc., can solve the problems of low adhesion fastness, low drying rate, low sensitivity, etc., to achieve low price, high drying rate, photosensitive Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

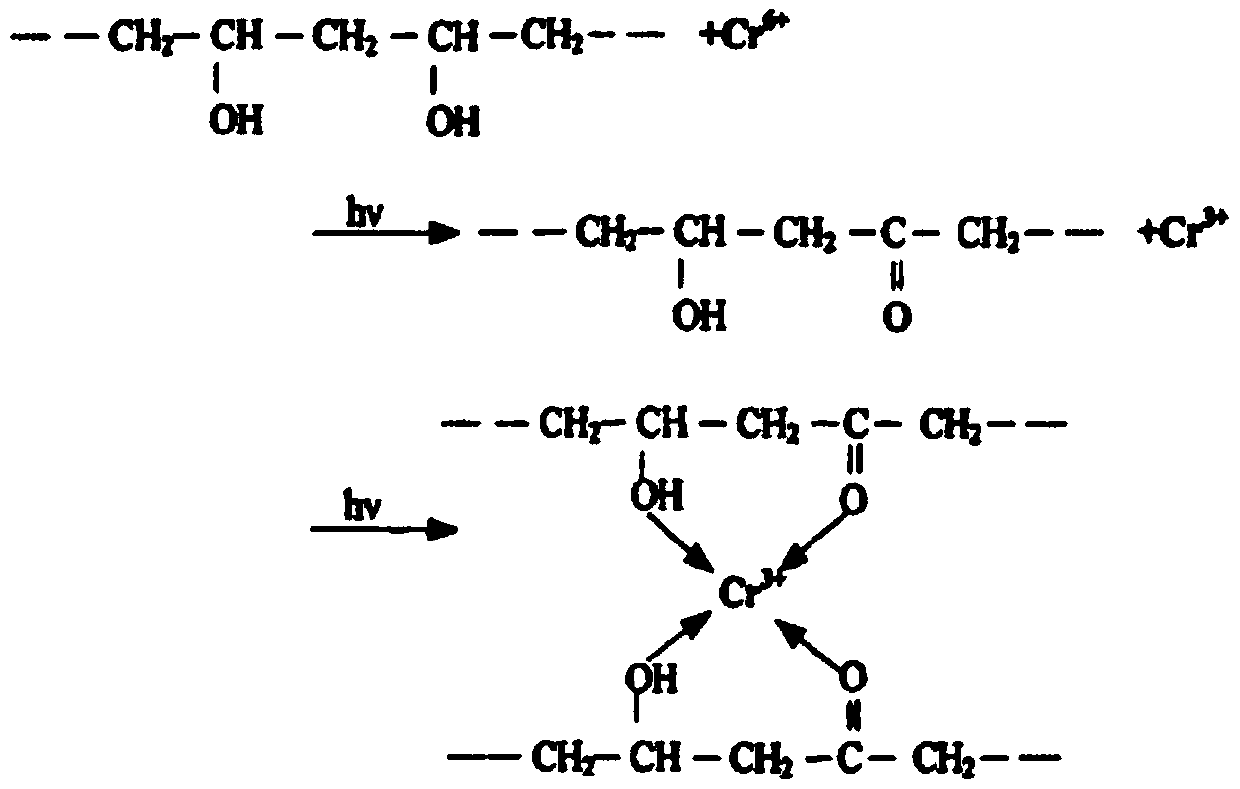

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of ultraviolet photocurable water-based gravure ink, specifically implemented according to the following steps:

[0055] Step 1, take the following raw materials respectively by mass percentage:

[0056] PVA17-88 8%, ammonium dichromate 6%, benzidine yellow GG8%, sodium nitrate 2%, industrial ethanol 4%, boric acid 1.5%, TS-103 defoamer 1.5%, urea 3%, the rest is deionized Water, the sum of the mass percentages of the above components is 100%;

[0057] Step 2, prepare PVA17-88 mixed solution

[0058] Slowly add PVA17-88 to 1 / 4 volume of deionized water at 19°C, and at the same time use a mixer to stir at 320r / h until PVA17-88 is fully swollen and dispersed, then raise the temperature to 90°C and stir evenly until PVA17-88 is completely Dissolve and keep warm for 2h to obtain PVA17-88 solution;

[0059] Add ammonium dichromate to 1 / 4 volume of deionized water, stir evenly to obtain ammonium dichromate solution, set aside;

[0060] Add industrial ...

Embodiment 2

[0064] A preparation method of ultraviolet photocurable water-based gravure ink, specifically implemented according to the following steps:

[0065] Step 1, take the following raw materials respectively by mass percentage:

[0066] PVA17-88 6%, ammonium dichromate 5%, sodium nitrate 1%, industrial ethanol 3%, benzidine yellow GG9%, TS-103 defoamer 1.5%, urea 2.5%, boric acid 0.5%, the rest is deionized Water, the sum of the mass percentages of the above raw materials is 100%;

[0067] Step 2, prepare PVA17-88 mixed solution

[0068] Slowly add PVA17-88 to 1 / 4 volume of deionized water at 20°C, and at the same time use a mixer to stir evenly at 300r / h until PVA17-88 is fully swollen and dispersed, then raise the temperature to 95°C and stir evenly until PVA17-88 is completely Dissolve and keep warm for 2h to obtain PVA17-88 solution;

[0069] Add ammonium dichromate to 1 / 4 volume of deionized water, stir evenly to obtain ammonium dichromate solution, set aside;

[0070] Add...

Embodiment 3

[0074] A preparation method of ultraviolet photocurable water-based gravure ink, specifically implemented according to the following steps:

[0075] Step 1, take the following raw materials respectively by mass percentage:

[0076] PVA17-88 6%, ammonium dichromate 4%, benzidine yellow HR 10%, industrial ethanol 3%, TS-103 defoamer 1.5%, urea 2.5%, boric acid 2%, sodium nitrate 1%, the rest is to Ionized water, the sum of the mass percentages of the above raw materials is 100%;

[0077] Step 2, prepare PVA17-88 mixed solution

[0078] Slowly add PVA17-88 to 1 / 4 volume of deionized water at 20°C, and at the same time use a mixer to stir evenly at 360r / h until PVA17-88 is fully swollen and dispersed, then raise the temperature to 95°C and stir evenly until PVA17-88 is completely Dissolve and keep warm for 2h to obtain PVA17-88 solution;

[0079] Add ammonium dichromate to 1 / 4 volume of deionized water, stir evenly to obtain ammonium dichromate solution, set aside;

[0080] Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com