A process for smelting manganese-rich slag from high-aluminum manganese-poor iron ore and high-sulfur coke

A high-aluminum manganese-poor iron ore and high-aluminum manganese ore technology, which is applied in the field of high-aluminum manganese-poor manganese ore and high-sulfur coke smelting manganese-rich slag technology, can solve the problems that cannot meet the requirements of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

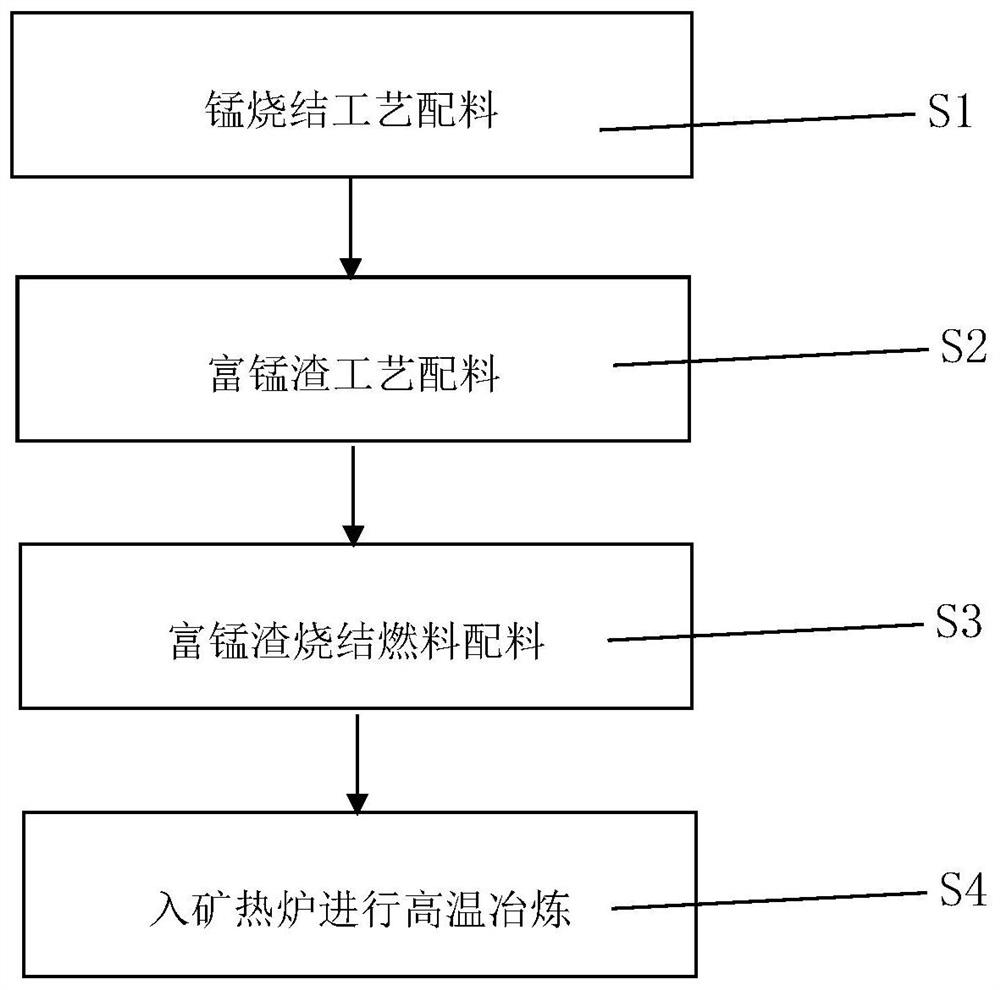

[0039] Such as figure 1 As shown, a process for smelting manganese-rich slag from high-aluminum manganese-poor iron ore and high-sulfur coke, the process of smelting manganese-rich slag is: manganese sintering process ingredients: use low manganese, high iron and high sulfur powder (Fe35-38%, Mn5- 10%, S≥0.4%, SiO2≥19-27%), South African high iron powder (Fe24-27%, Mn26-27.5%, AL2O3≥3-7%) and domestic high sulfur iron powder (Fe64-65%, S≥2.6-3.0%) are used as raw materials for sintering production; manganese-rich slag process ingredients: use manganese sintering process to produce manganese sinter (Mn13-15%, Fe39-45%) with 60%, high aluminum manganese ore (Fe20 -23%, Mn29-33%, AL2O3≥9-12%) add 30%, low manganese high iron ore (Mn5-10%, Fe35-38%, S≥0.5%, P≥0.3%) add 10% %; Manganese-rich slag sintering fuel ingredients: use fuel ratio 85 high-sulfur coke (C85%, S≥1.5-2.0, A≤13.5%, CSR≥55%, CRI≤25-28%) with 60%, 80% Coke (C80%, S≥1.0-1.2, A≤16-18%, CSR≥60%, CRI≤26%) is mixed w...

Embodiment 2

[0041] Such as figure 1 As shown, a process for smelting manganese-rich slag with high-aluminum manganese-poor iron ore and high-sulfur coke, the process for smelting manganese-rich slag is: manganese-rich slag process ingredients: manganese sintered ore (Mn13-15% , Fe39-45%) with 60%, high aluminum manganese ore (Fe20-23%, Mn29-33%, AL2O3≥9-12%) with 30%, low manganese high iron ore (Mn5-10%, Fe35- 38%, S≥0.5%, P≥0.3%) with 10%; manganese-rich slag sintered fuel ingredients: use fuel ratio 85 high-sulfur coke (C85%, S≥1.5-2.0, A≤13.5%, CSR≥ 55%, CRI≤25-28%) add 60%, 80 coke (C80%, S≥1.0-1.2, A≤16-18%, CSR≥60%, CRI≤26%) add 40%, tons The slag-coal ratio is 70kg, the oxygen enrichment rate is 5.5%, and it is put into the submerged arc furnace for high-temperature smelting: put the prepared manganese-rich slag raw material and manganese-rich slag sintering fuel into the submerged arc furnace and use the pyroenrichment technology for smelting. The process of smelting Medium tem...

Embodiment 3

[0043] Such as figure 1 As shown, a process for smelting manganese-rich slag with high-aluminum manganese-poor iron ore and high-sulfur coke, the process for smelting manganese-rich slag is: manganese-rich slag process ingredients: manganese sintered ore (Mn13-15% , Fe39-45%) with 60%, high aluminum manganese ore (Fe20-23%, Mn29-33%, AL2O3≥9-12%) with 30%, low manganese high iron ore (Mn5-10%, Fe35- 38%, S≥0.5%, P≥0.3%) with 10%; manganese-rich slag sintered fuel ingredients: use fuel ratio 85 high-sulfur coke (C85%, S≥1.5-2.0, A≤13.5%, CSR≥ 55%, CRI≤25-28%) add 60%, 80 coke (C80%, S≥1.0-1.2, A≤16-18%, CSR≥60%, CRI≤26%) add 40%, tons The slag-coal ratio is 70kg, the oxygen enrichment rate is 5.5%, and it is put into the submerged arc furnace for high-temperature smelting: put the prepared manganese-rich slag raw material and manganese-rich slag sintering fuel into the submerged arc furnace and use the pyroenrichment technology for smelting. The process of smelting Medium tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com