Conveying mechanism of efficient and accurate robot cutting system for poultry meat products

A conveying mechanism and robot technology, which is applied in meat cutting/trimming, meat processing/transportation/packaging, application, etc., can solve the problems of unsuitable batch production, different product sizes, cumbersome operation, etc., and achieve increased The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

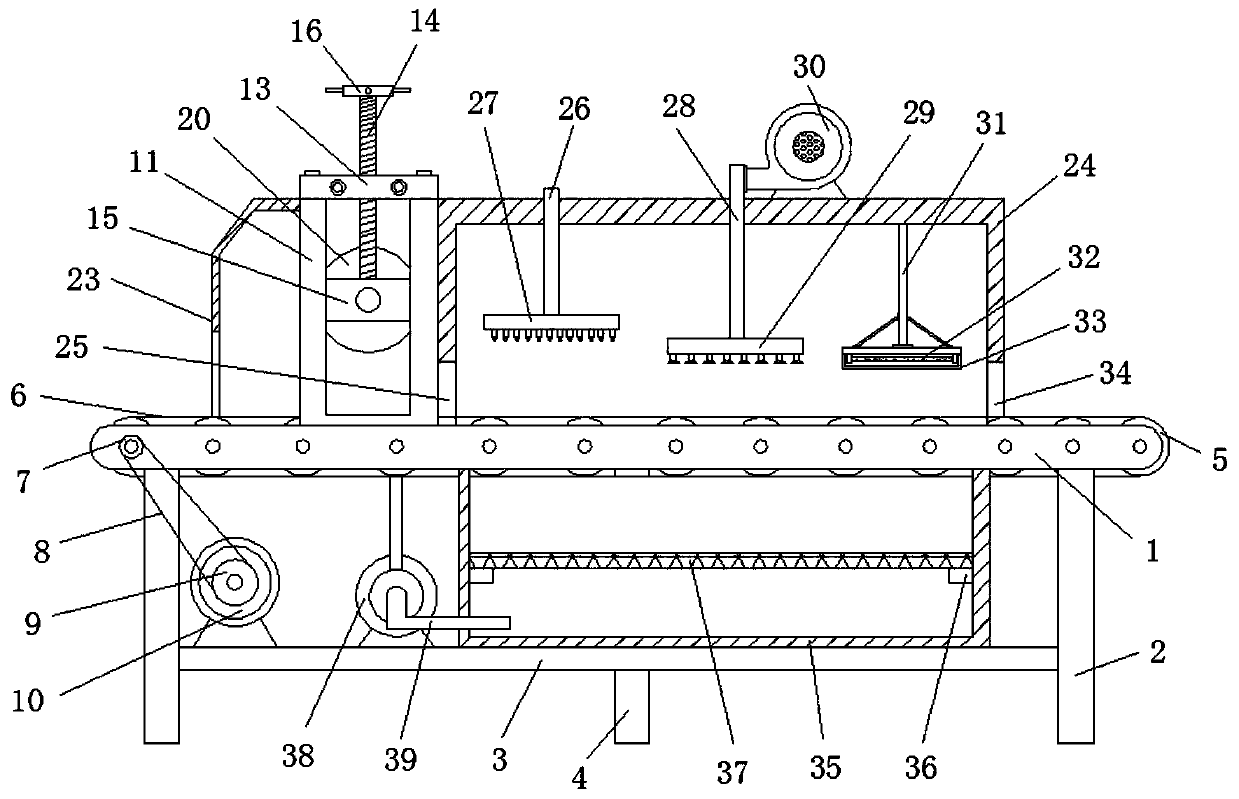

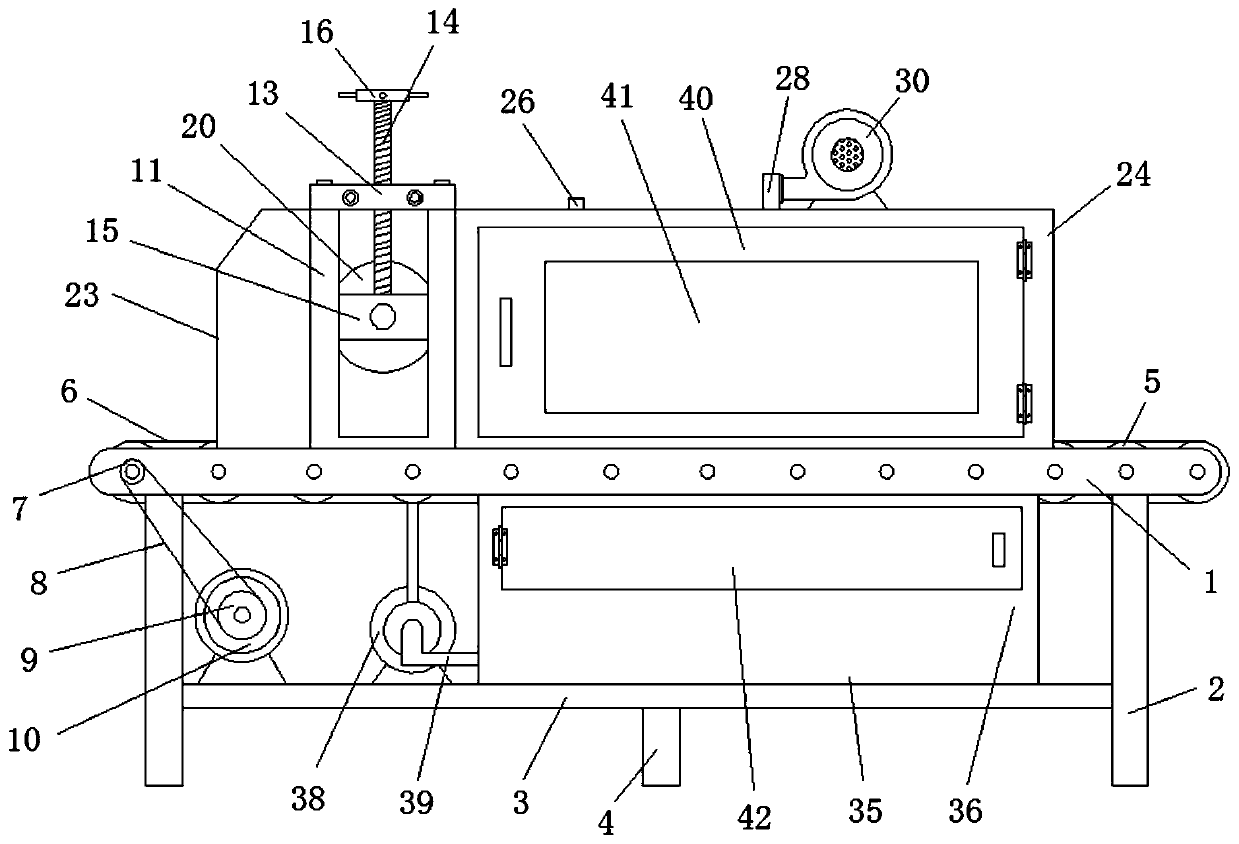

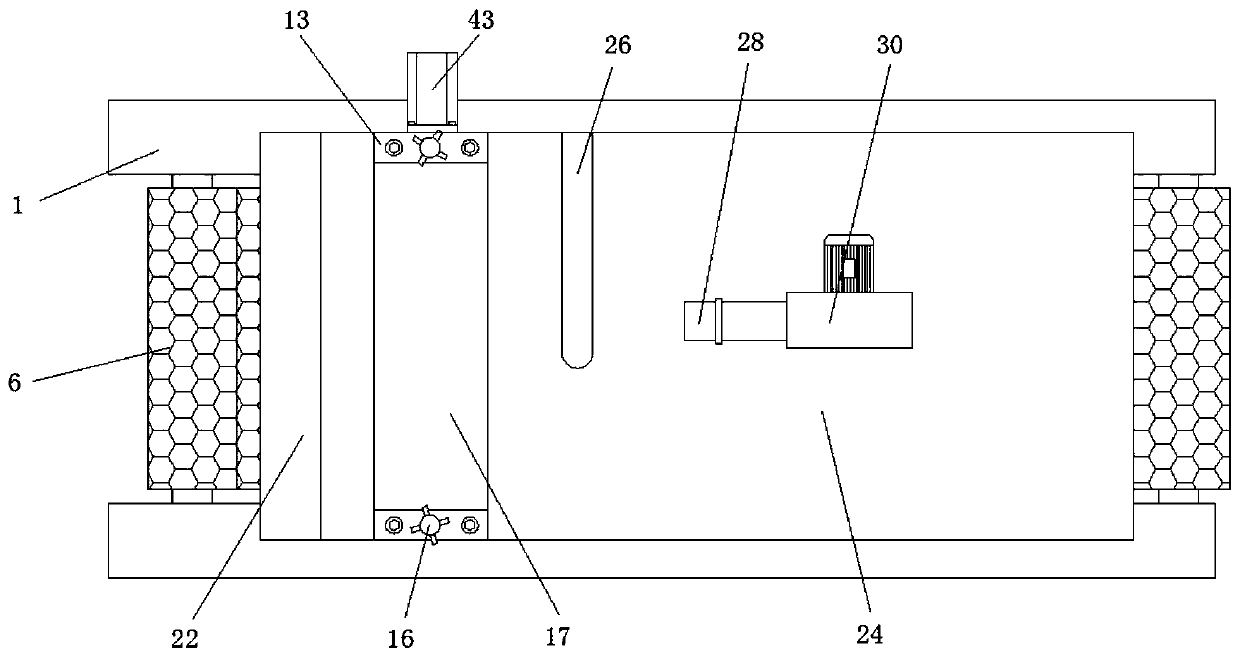

[0035] see Figure 1-5 , this embodiment provides a conveying mechanism for an efficient and precise robotic segmentation system for livestock and poultry meat products, including a workbench 1, four corners of the lower end of the workbench 1 are fixedly connected with support feet 2, and the support feet 2 A base 3 is fixedly connected between them, and several rollers 5 are connected to the inner rotation of the workbench 1, and mesh conveyor belts 6 are wound on the several rollers 5, and the outermost roller 5 is fixedly connected with The driven pulley 7, the upper surface side of the base 3 is fixedly connected with a motor 10, the output shaft of the motor 10 is fixedly connected with a driving pulley 9, and the driving pulley 9 and the driven pulley 7 pass through a belt 8 Connected and fixed, the upper surface of the workbench 1 is fixedly connected with a sliding frame 11, the upper surface of the sliding frame 11 is provided with a sliding groove 12, and the top of...

Embodiment 2

[0039] see Figure 1-5 , on the basis of Example 1, a further improvement is made: the middle part of the lower surface of the base 3 is fixedly connected with a reinforced support foot 4, and the number of the reinforced support feet 4 is set in two, and two of the reinforced support feet 4 Symmetrically arranged to facilitate the support of the base 3 and increase the strength of the base 3, the two sides of the sliding plate 15 are fixedly connected with protrusions that match the sliding groove 12, and the protrusions are on the sides of the sliding groove 12. The interior is free to slide, which is convenient for the slide plate 15 to slide more smoothly, and avoids jamming or tilting. The water pipe 26 is detachably connected to the water spray tray 27, and the water spray tray 27 is fixedly connected with several A water spray nozzle is convenient for the disassembly and maintenance of the water spray plate 27, and the water spray nozzle can spray water evenly for clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com