A kind of bio-based composite hydrogel fire extinguishing material and preparation method thereof

A technology of composite hydrogel and fire extinguishing materials, applied in the field of bio-based composite hydrogel fire extinguishing materials and its preparation, to achieve the effects of strong chemical resistance, dilution of flammable gas concentration, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Stir and mix 1.5 parts of carboxymethyl cellulose, 1.5 parts of montmorillonite, 2.5 parts of sodium bicarbonate, 2.5 parts of potassium bicarbonate and 80 parts of tap water at 3000 r / min at 20°C for 3 minutes to obtain the first mixed solution; Stir and mix 0.5 parts of aluminum citrate and 11.5 parts of tap water at 3000r / min at 20°C for 3 minutes to obtain the second mixed solution; mix the first mixed solution and the second mixed solution at 3000r / min at 20°C Stir and mix for 3 minutes to prepare a gel slurry.

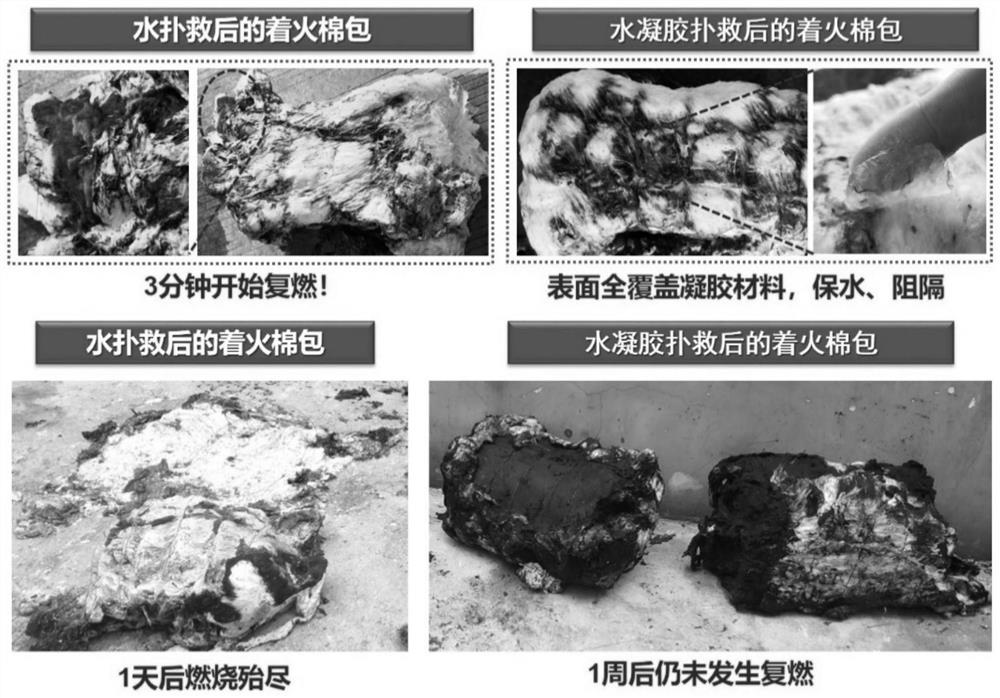

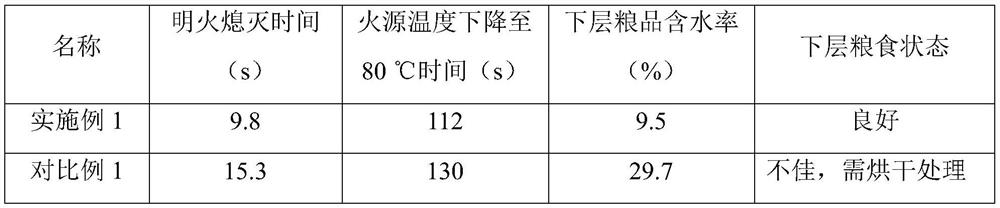

[0035] Start the grouting pump to deliver the gel slurry, and spray 10kg of the gel slurry on the burning rice pile (the rice sample comes from the Scientific Research Institute of the State Grain and Material Reserve Bureau, with an initial water content of 9.5%). The gel slurry quickly formed a gel on the surface of the rice heap. After gelation, the gel covered the surface of the high-temperature rice heap. The open flame was extinguished in 9.8s, and t...

Embodiment 2

[0042] 1.5 parts of gelatin, 1.5 parts of vermiculite, 3 parts of potassium bicarbonate, 3 parts of ammonium bicarbonate and 85 parts of distilled water were stirred and mixed at 1000 r / min for 30 minutes at 30°C to obtain the first mixed solution; 0.25 parts of citric acid Aluminum, 0.35 parts of aluminum gluconate and 5.4 parts of distilled water were stirred and mixed for 30 minutes at 30°C at 1000r / min to obtain the second mixed solution; the first mixed solution and the second mixed solution were mixed at 30°C at 1000r / min Stir and mix for 30 minutes to prepare a gel slurry.

[0043] Start the grouting pump to pump the gel slurry, and spray 10kg of the gel slurry on the burning wheat pile (the wheat sample comes from the Scientific Research Institute of the State Grain and Material Reserve Bureau, with an initial water content of 7.9%). The gel slurry quickly formed a gel on the surface of the wheat heap. After gelation, the gel covered the surface of the high-temperature...

Embodiment 3

[0050] Stir and mix 2 parts of sodium alginate, 1.5 parts of layered double hydroxide, 3 parts of sodium bicarbonate, 3 parts of potassium bicarbonate and 83 parts of tap water at 5000r / min for 30s at 37°C to obtain the first mixed solution ; 0.5 parts of aluminum gluconate and 7 parts of tap water were stirred and mixed at 5000r / min for 30s at 37°C to obtain the second mixed solution; the first mixed solution and the second mixed solution were stirred and mixed at 5000r / min for 30s, A gel slurry is formed.

[0051] Start the grouting pump to pump the gel slurry, and spray 10kg of the gel slurry on the burning rice pile (the rice sample comes from the Scientific Research Institute of the State Grain and Material Reserve Bureau, with an initial moisture content of 9.5%). The gel slurry quickly formed a gel on the surface of the rice heap. After gelation, the gel covered the surface of the high-temperature rice heap. The open flame was extinguished in 7.5s, and the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com