A multiphase separation method, device and application thereof

A multi-phase separation and porous membrane technology, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of limited application, lack of responsiveness of liquid composite membrane system, etc., to increase the scope of application, enrich the The effect of multiphase separation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

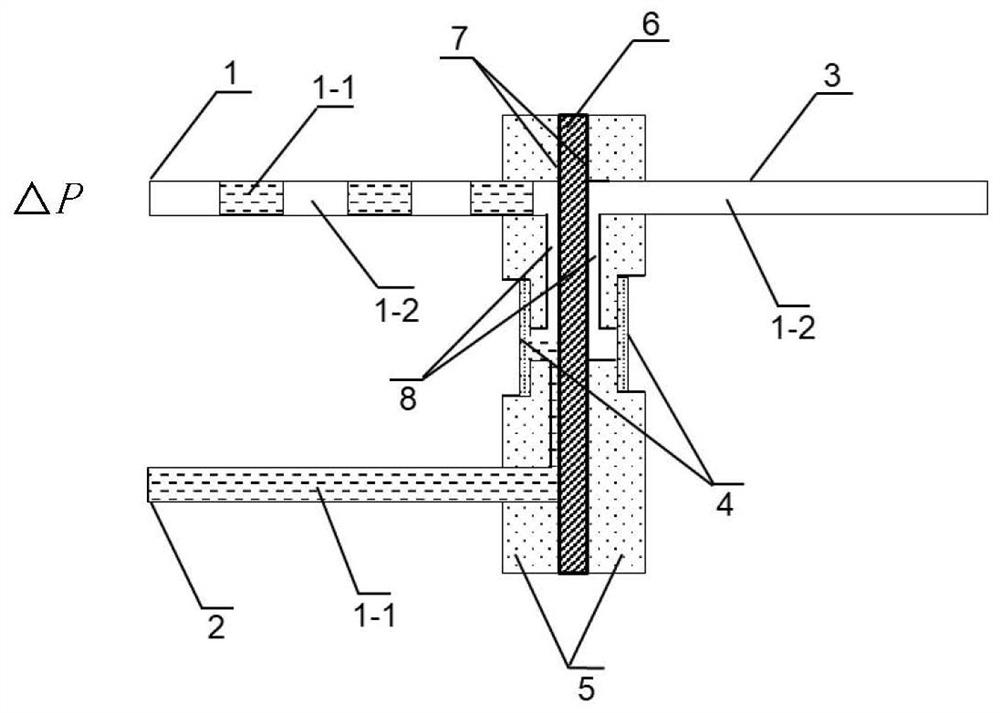

[0038] Example 1 - Marangoni flow induced by thermal field

[0039] Select two solid materials with large differences in thermal conductivity (including but not limited to copper and silicon dioxide, copper and conductive glass), now take conductive glass and copper as an example, deposit copper particles at specific positions on the surface of conductive glass with array holes , and combined with specific functional liquids (perfluorinated lubricant Krytox 103, simethicone, paraffin, etc.) to form a heat-responsive liquid composite film6. Taking gas-liquid separation as an example, according to figure 1 In the manner shown, the heat-responsive liquid composite membrane 6 is sealed, and a certain pressure is input to the area containing copper particles in the input channel 1 through a syringe pump (higher than the pressure of the gas phase passing through the membrane after applying the thermal field, lower than that before the thermal field is applied) The gas-liquid mixture ...

Embodiment 2

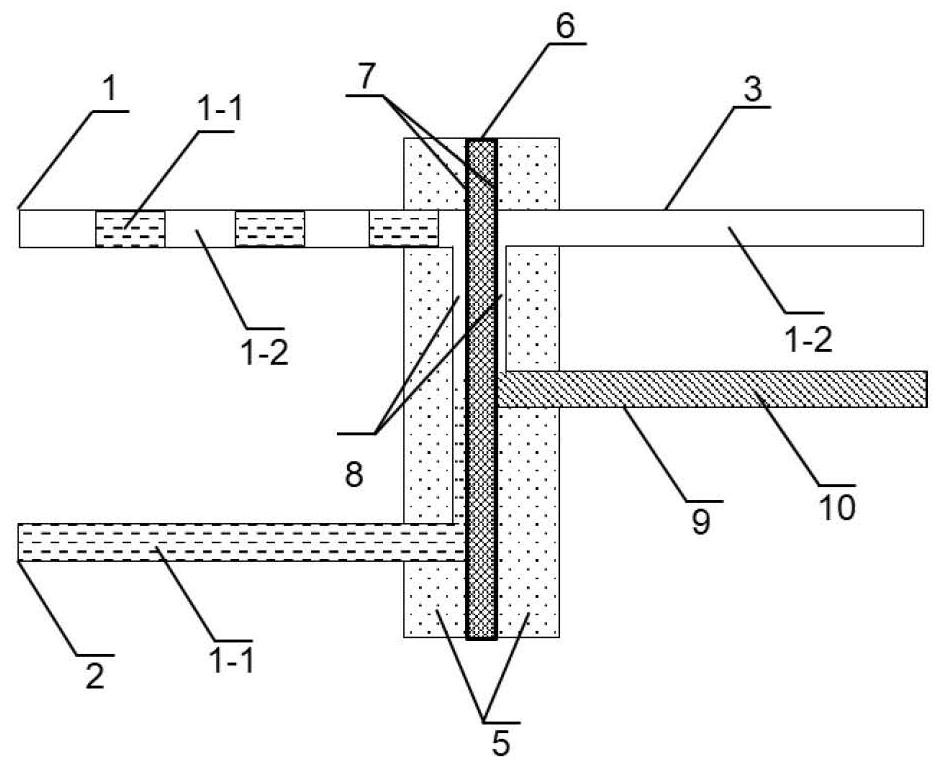

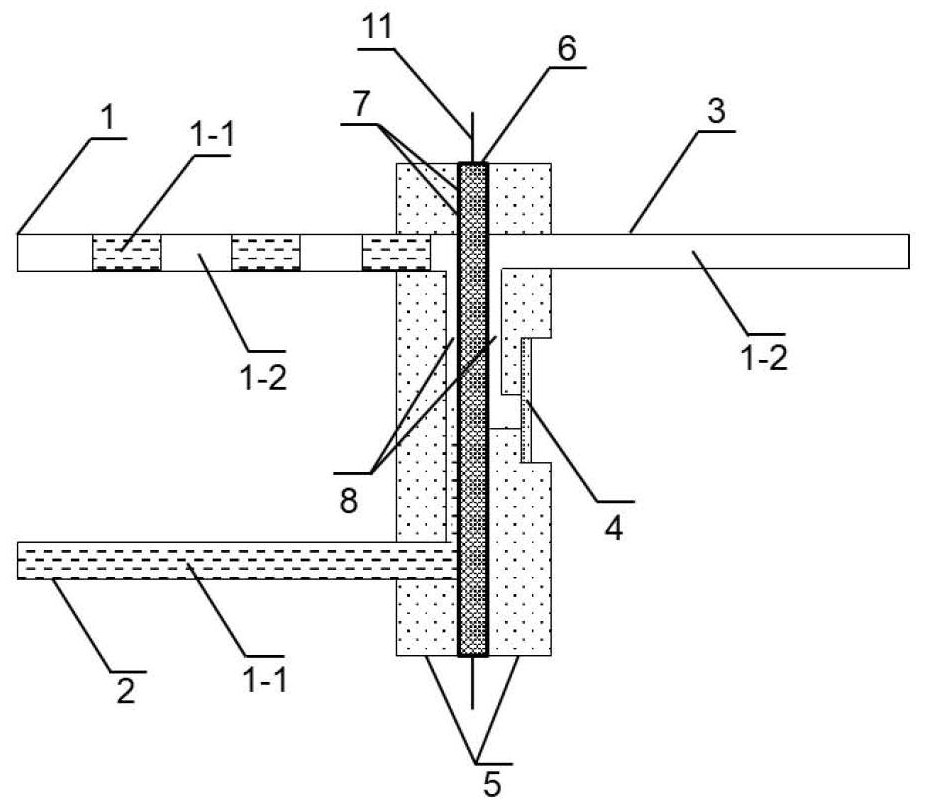

[0040] Example 2 - Light and heat induced Marangoni flow

[0041] Select a functional liquid whose surface tension changes greatly with temperature (including but not limited to Krytox 103, polydimethylsiloxane), inject it into the solid porous membrane, and form a photoresponsive liquid composite membrane 6 . Taking gas-liquid separation as an example, according to figure 1 In the manner shown, the photoresponsive liquid composite membrane 6 is sealed, and the gas-liquid mixture 1-1, 1-2 with a certain pressure ΔP is input into the input channel 1 through a syringe pump. Such as image 3 It can be seen that when the light source is turned off, neither the gas phase nor the liquid phase can pass through the liquid composite membrane 6, and both the gas and liquid flow out from the output channel 2, and the separation of the gas phase and the liquid phase cannot be realized; when the light source is turned on, if figure 2 As shown, the heat generated when light is irradiated...

Embodiment 3

[0042] Example 3 - Light and heat induced Marangoni flow

[0043] Select a porous membrane with good photothermal performance (including but not limited to stainless steel metal mesh, carbon-based porous membrane), and compound it with a specific functional liquid (Krytox 103, simethicone, paraffin, etc.) to form a photoresponsive liquid Composite film6. Taking gas-liquid separation as an example, according to figure 1 In the manner shown, the photoresponsive liquid composite membrane 6 is sealed, and the gas-liquid mixture 1-1, 1-2 with a certain pressure ΔP is input into the input channel 1 through a syringe pump. Such as image 3 It can be seen that when the light source is turned off, neither the gas phase nor the liquid phase can pass through the liquid composite membrane 6, and both the gas and liquid flow out from the output channel 2, and the separation of the gas phase and the liquid phase cannot be realized; when the light source is turned on, if figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com