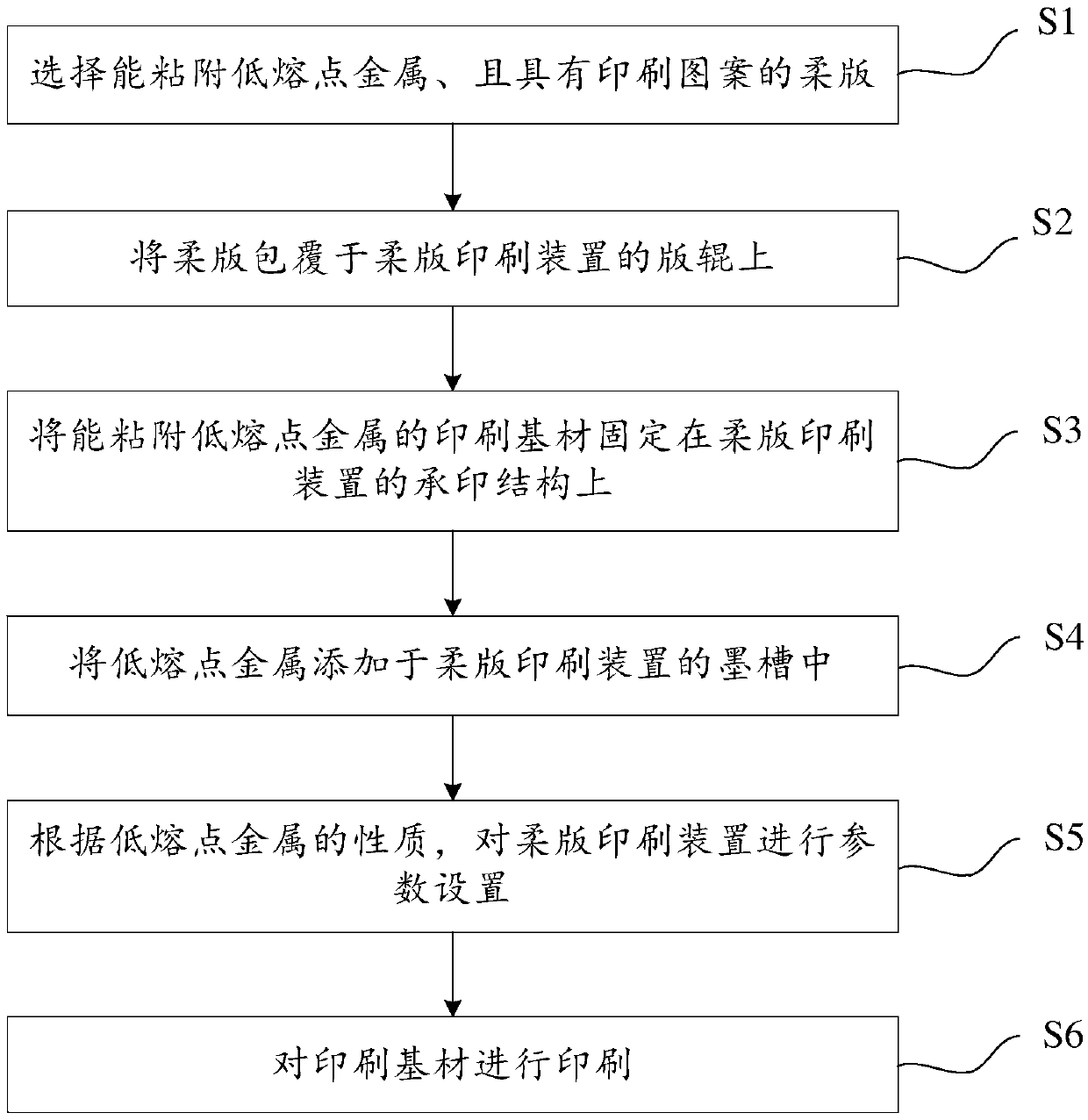

Flexographic printing method

A flexographic printing and flexographic technology, applied in the field of low-melting point metals, can solve the problems of low printing efficiency, difficult to control the printing process, poor printing effect, etc., and achieve good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

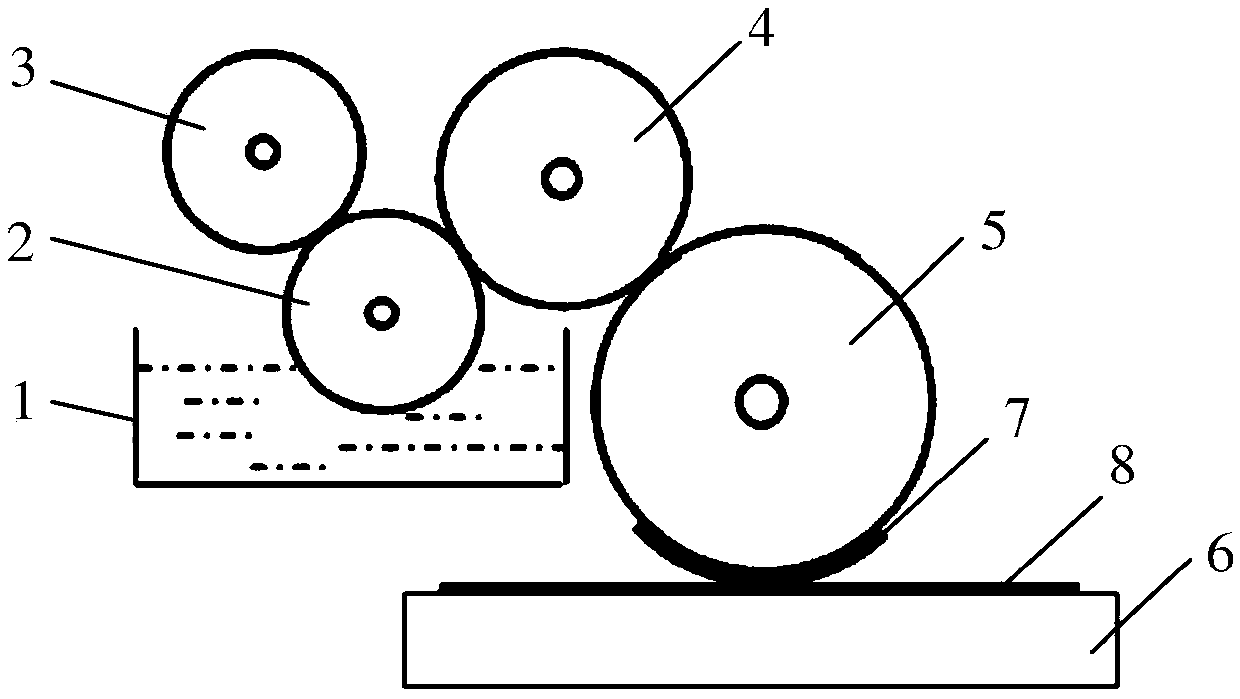

Method used

Image

Examples

Embodiment 1

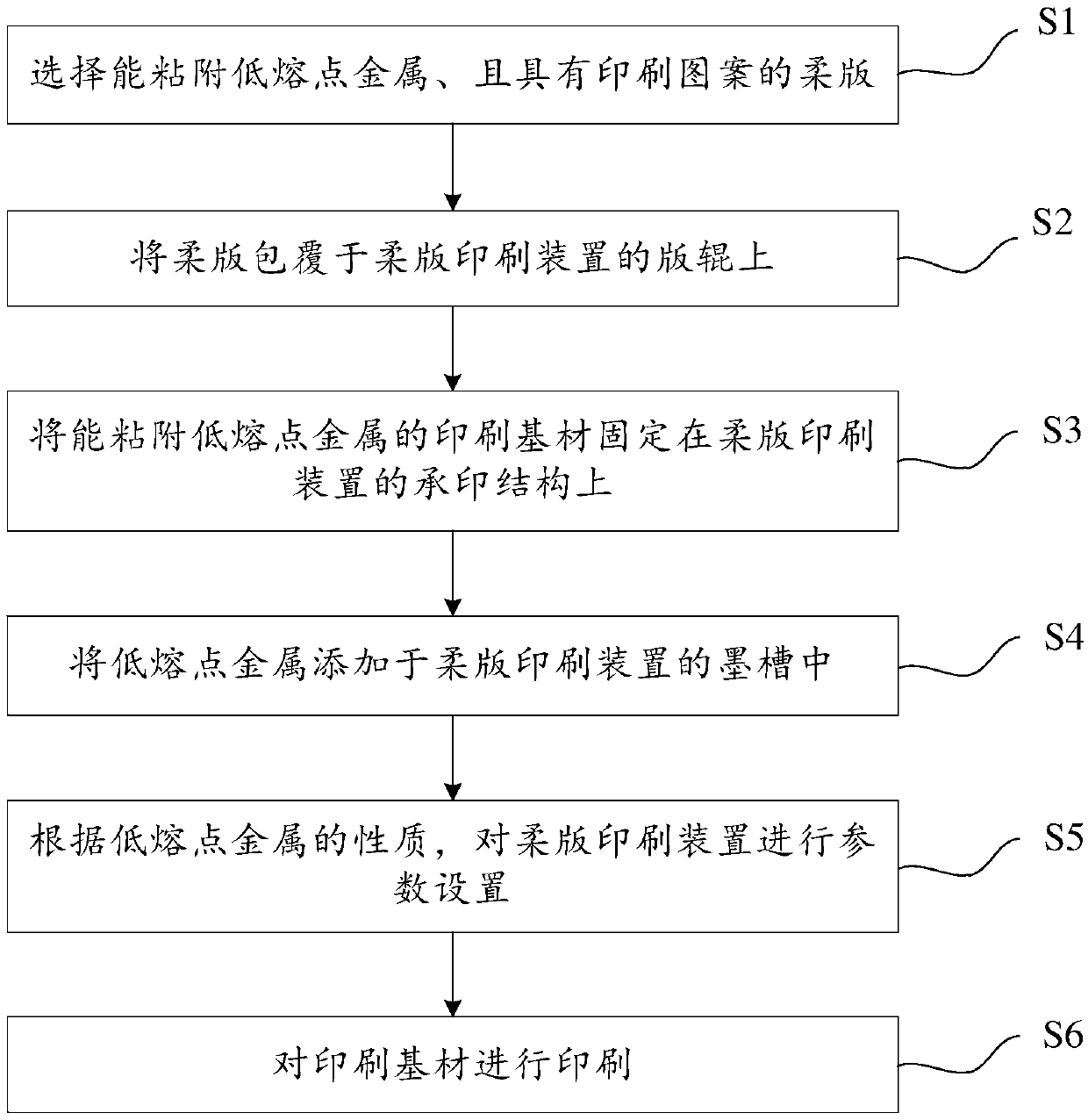

[0073] Stretchable circuits printed with low-melting point metals on silicone surfaces using flexographic methods include:

[0074] (1) Fix the customized polyurethane flexo plate with functional circuit on the surface of the plate roller;

[0075] (2) Cut the silicone into 20cm*30cm and fix it on the printing platform;

[0076] (3) Add a low melting point metal with a melting point of 11°C (Ga67%In20.5%Sn12.5%) to the ink tank of the flexographic printing device;

[0077] (4) Adjust the press-in amount between the ink outlet roller and the ink tank, the ink outlet roller and the string ink roller, the ink outlet roller and the ink form roller, the version roller and the ink form roller, the version roller and the silica gel to 0.5mm, and adjust the distance between each roller. The pressure between the roller and the silica gel is 50N, the pressure between the plate roller and the silica gel is 70N, and the flexographic printing device is started to print the silica gel;

...

Embodiment 2

[0081] Printing of smart packaging graphics with low-melting point metals on the surface of kraft paper using flexographic printing methods includes:

[0082] (1) Fix the customized polyvinyl alcohol flexo plate with packaging pattern on the surface of the plate roller;

[0083] (2) After the kraft paper with a format of A4 is sprayed with a concentration of 20% polyurethane solution, it is dried in an oven at 80°C for 20 minutes and then fixed on the printing platform;

[0084](3) adding a GaIn alloy (Ga75.5%In24.5%) containing 4% nickel powder (particle size: 1.5 microns) with a melting point of 15.5°C to the ink tank of the flexographic printing device;

[0085] (4) Adjust the pressing amount between the ink outlet roller and the ink tank, the ink outlet roller and the string ink roller, the ink outlet roller and the ink form roller, the version roller and the ink form roller, the version roller and the kraft paper to 0.5mm, and adjust the distance between each roller. The...

Embodiment 3

[0089] Printing RFID tags with low-melting-point metals on the surface of cotton cloth using flexographic printing methods includes:

[0090] (1) Fix the customized silicone flexo plate with RFID label on the surface of the plate roller;

[0091] (2) Cut the cotton cloth into a sheet of 40cm*40cm, spray it with a water-based acrylate primer with a concentration of 15%, dry it in an oven at 80°C for 20 minutes, and then fix it on the printing platform;

[0092] (3) GaIn alloy (Ga75.5%In24.5%) with a melting point of 15.5°C containing 5% nickel powder (particle size of 1.5 microns) and 15% silver-clad copper powder (particle size of 20 microns) was added to In the ink tank of the flexographic printing unit;

[0093] (4) Adjust the press-in amount between the ink outlet roller and the ink tank, the ink outlet roller and the ink roller, the ink outlet roller and the ink form roller, the version roller and the ink form roller, the version roller and the cotton cloth to 1.0 mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com