Special cementing agent for self-curing pervious concrete and application thereof

A technology of permeable concrete and cement, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of reducing shrinkage cracking, reducing shrinkage, and strength shrinkage, so as to reduce concrete cracks and reduce shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

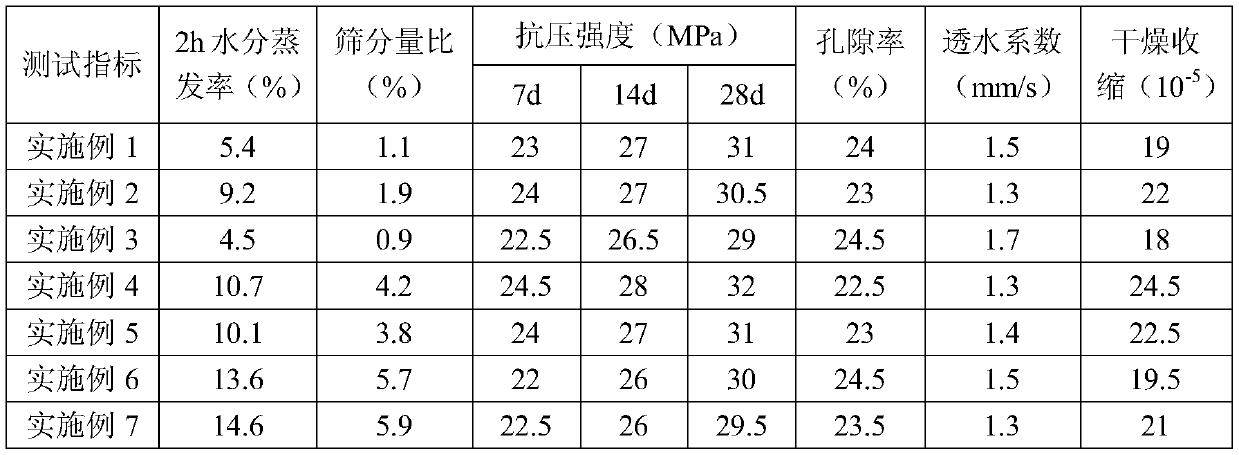

Examples

Embodiment 1

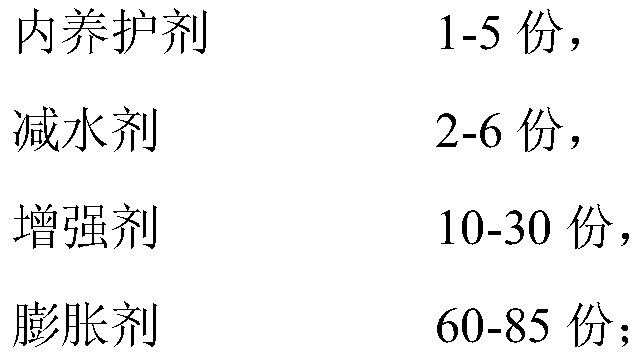

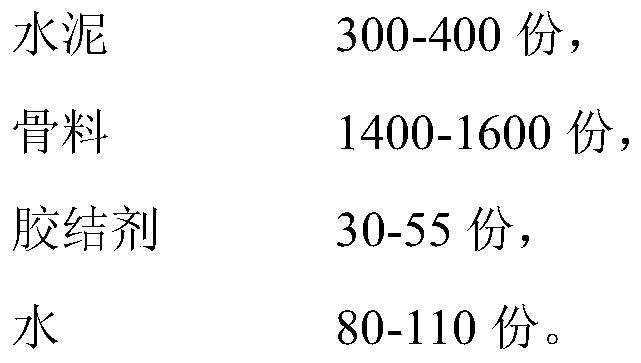

[0022] Example 1: 0.2-0.3mm polyacrylonitrile hydrolyzate, polycarboxylate high-performance water reducer, silica fume + latex powder, and ettringite expansion agent in mass parts ratio = 2:3:20: 75. Mix and stir evenly to obtain a self-curing permeable concrete cement; when preparing concrete according to the concrete ratio in the content of the invention, the amount of the above cement is 10% of the mass of the adhesive material.

Embodiment 2

[0023] Example 2: 0.2-0.3mm polyacrylonitrile hydrolyzate, polycarboxylate high-performance water reducer, silica fume + latex powder, and ettringite expansion agent in parts by mass ratio = 2:3:20: 75; Mix and stir evenly to obtain self-curing permeable concrete cement; when preparing concrete according to the concrete ratio in the content of the invention, the amount of the above cement is 8% of the amount of glue.

Embodiment 3

[0024] Example 3: 0.2-0.3mm modified polyvinyl alcohol, polycarboxylate high-performance water reducer, silica fume + latex powder, and ettringite expansion agent in mass parts ratio = 2:3:20: 75. Mix and stir evenly to obtain a self-curing permeable concrete cement; when preparing concrete according to the concrete ratio in the content of the invention, the amount of the above cement is 12% of the amount of adhesive material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com