High temperature resistant consolidated material and its construction method

A technology for consolidating materials and construction methods, applied in chemical instruments and methods, liquid batching supply devices, clay preparation devices, etc., can solve the disadvantages of insufficient time, economy and effectiveness to ensure the safe use of ordinary concrete protective engineering structures, To solve problems such as heavy maintenance and repair work, it can improve the thermal shock resistance and erosion resistance, improve the bulk density and strength, and reduce the porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

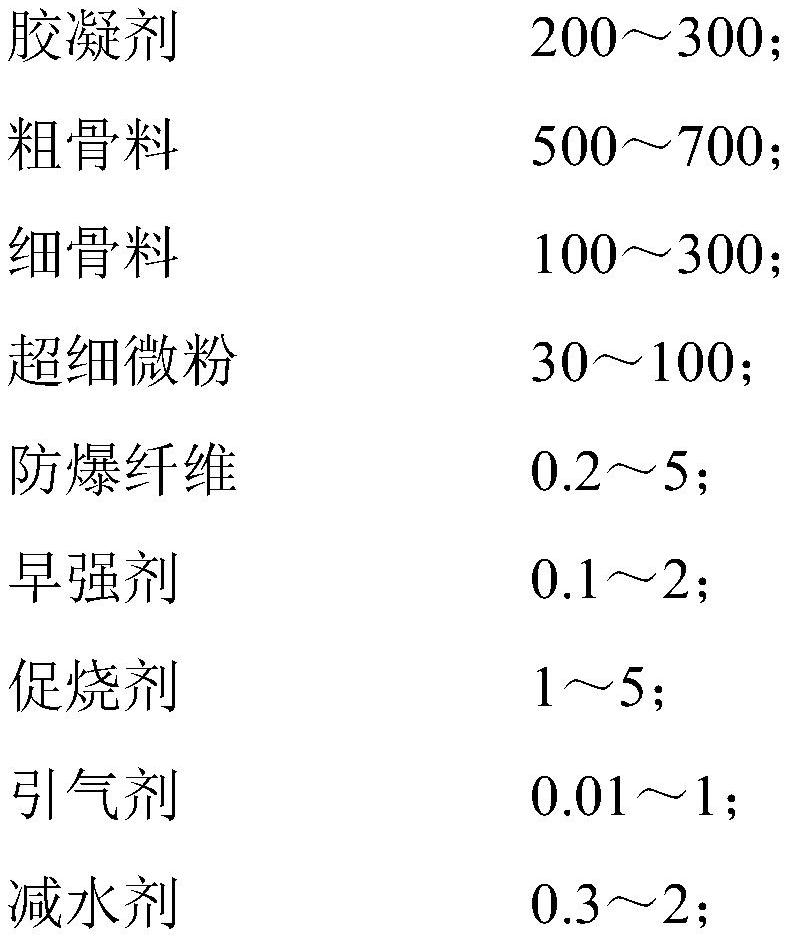

Method used

Image

Examples

Embodiment 1-3

[0039] The gelling agent is A80 aluminate cement and A60 aluminate cement in a ratio of 1:1, A80 aluminate cement and A70 aluminate cement in a ratio of 1:1, A80 aluminate cement and A50 aluminate Salt cement is compounded at a ratio of 1:1.

[0040] Coarse aggregates are high alumina materials and secondary bauxite.

[0041]The fine aggregates are secondary bauxite, silicon carbide, and brown corundum, and they are all distributed in the five particle size ranges of 10-8mm, 8-5mm, 5-3mm, 3-1mm, and 1-0.1mm, and in The proportion of fine aggregate in the five particle size ranges to the total fine aggregate is the same.

[0042] The ultrafine powders are composites of activated alumina micropowders and silica micropowders, and the ratios of the two in Examples 1-3 are 1:1, 1.5:1 and 1:1.5, respectively.

[0043] The explosion-proof fibers are all polypropylene fibers, and in Examples 1-3, the length is 3 mm and the fineness is 40 μm.

[0044] The early strength agents are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com