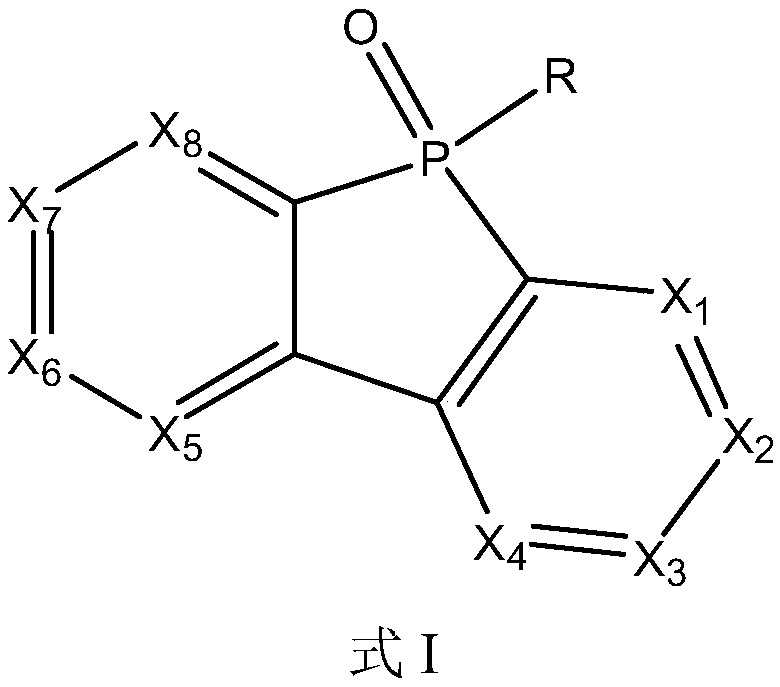

Organic light-emitting material and OLED device comprising same

A light-emitting material, organic technology, applied in the direction of light-emitting materials, organic chemistry, electric solid devices, etc., can solve problems such as insufficient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In this example, compound 1 was prepared by the following method, and the preparation route is as follows:

[0088]

[0089] Compound 1-1 (62.5g, 233.4mmol) was placed in phosphorus trichloride (30.5ml, 350.1mmol), and the compound was heated at 220°C for 3h. Heating was stopped and extracted with tetrahydrofuran, the resulting solid was dissolved in ethanol (600ml) and heated to 80°C, then 10% aqueous potassium hydroxide solution (200ml) was added dropwise to the solution. Then the obtained solid was filtered, recrystallized three times from toluene, and finally purified by sublimation to obtain compound 1-2. Compound 1-2 (26.1g, 83.3mmol), bromobenzene (8.7g, 83.3mmol), cesium carbonate (54.3g, 166.6mmol) and dichloro(1,3-bis(diphenylphosphino)propane) Nickel (4.5 g, 8.3 mmol) was placed in dioxane, and the mixture was refluxed for 1 h. After the reaction was completed, a solid obtained by vacuum distillation of the resultant was extracted with chloroform and wat...

Embodiment 2

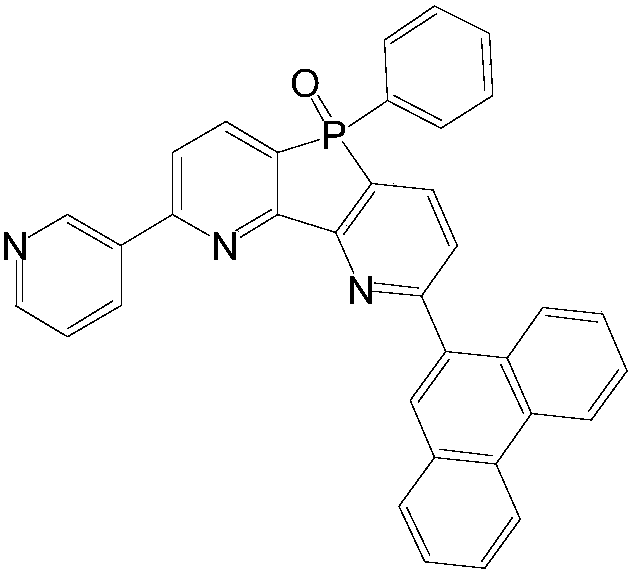

[0093] In this example, the preparation method of compound 2 is the same as that of compound 1, the only difference is that its preparation raw materials are different (compounds 2-1 and 2-5 are used as raw materials), and compound 2 can be obtained after final sublimation and purification (yield 81% ), the specific synthetic route is as follows:

[0094]

[0095] Characterization data of compound 2:

[0096] Tg(DSC) 141°C, purity 99.9%; 1 H NMR (400MHz, CDCl 3 )δ (ppm): 8.81 (s, 1H), 8.55 (d, 1H), 8.05 (d, 2H), 7.97 (d, 1H), 7.91 (d, 4H), 7.70 (m, 2H), 7.60 ( d,1H),7.57(d,2H),7.48(d,2H),7.44(m,1H),7.40(d,2H),7.39(m,4H),7.32(m,2H),7.30(m ,5H), 7.22(m,1H).

Embodiment 3

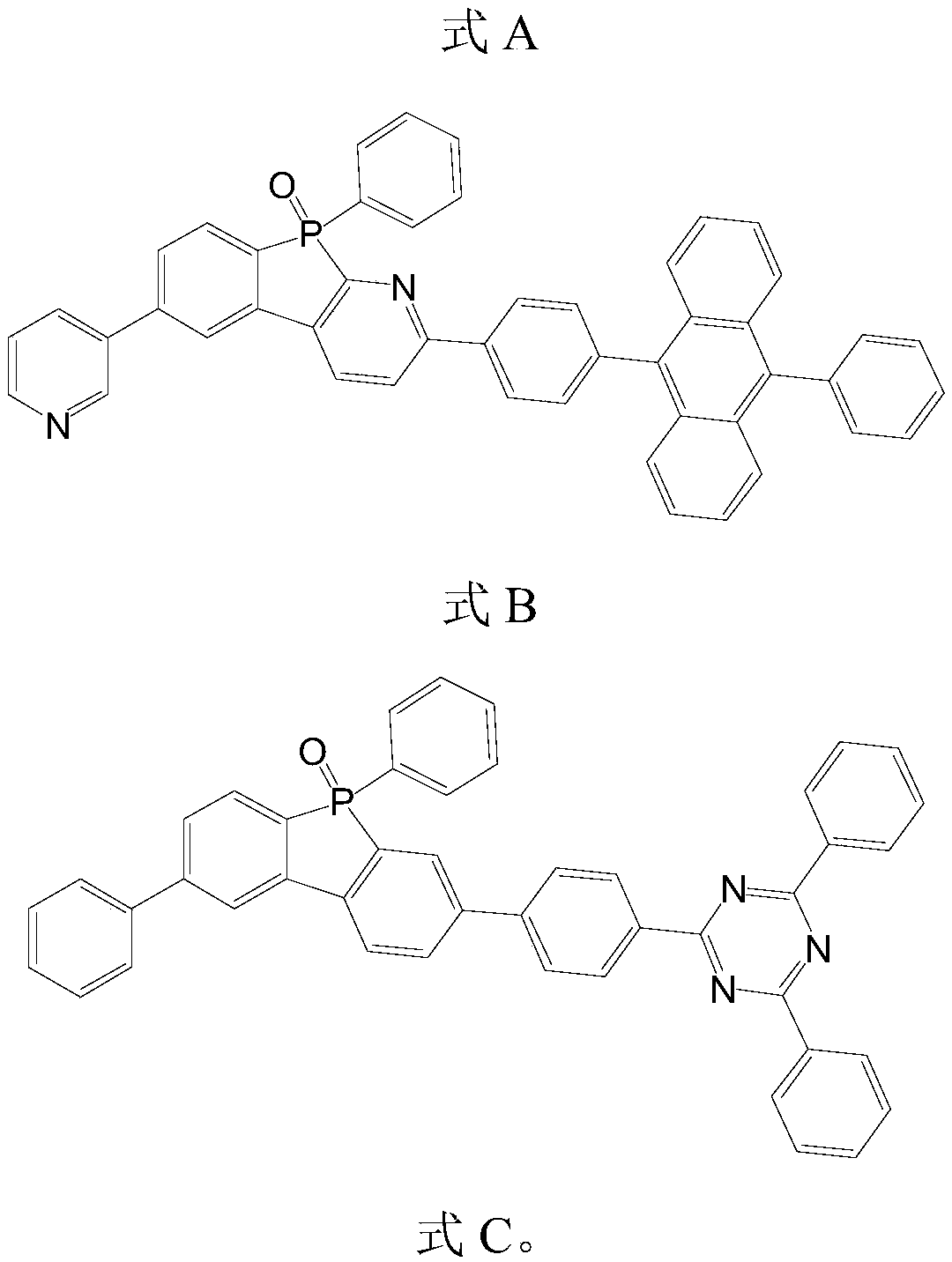

[0098] In this example, the preparation method of compound 3 is the same as that of compound 1, the difference is only that the raw materials for its preparation are different (compounds 3-1 and 3-6 are used as raw materials), and finally compound 3 can be obtained after sublimation and purification (yield 89% ), the specific synthetic route is as follows.

[0099]

[0100] Characterization data of compound 3:

[0101] Tg(DSC) 148°C, purity 99.9%; 1 H NMR (400MHz, CDCl 3 )δ(ppm): 7.70(s,1H),7.54(d,4H),7.50(m,3H),7.48(d,6H),7.40(d,2H),7.32(m,6H),7.30( m,5H), 7.22(m,3H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com