Flame-retardant heat-conducting coating and preparation method thereof

A heat-conducting coating and flame retardant technology, applied in the direction of fire-resistant coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of low yield, foaming of synthetic resin products, uneven surface, etc., to increase thermal conductivity , Not easy to settle, evenly dispersed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

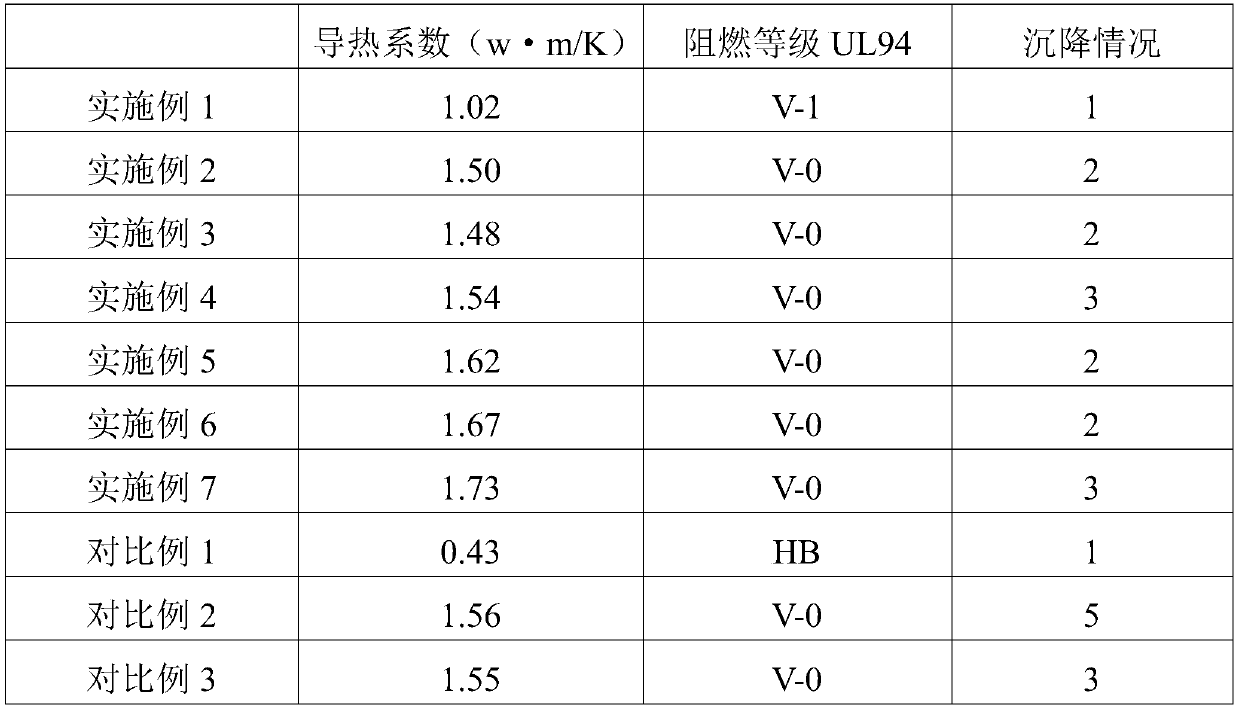

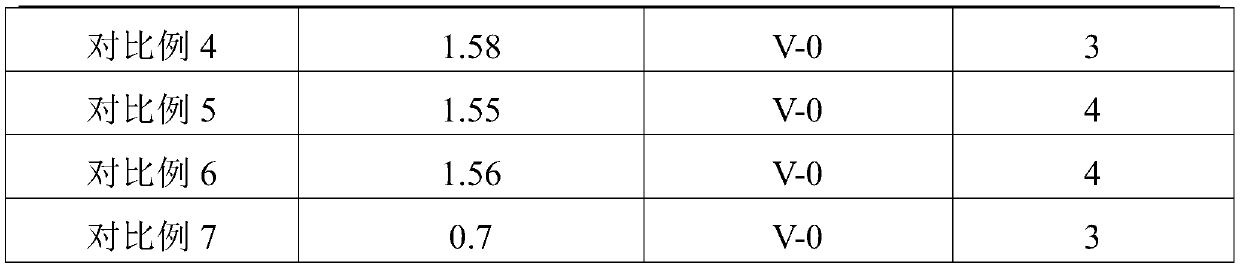

Examples

preparation example Construction

[0031] In some embodiments of the present invention, the preparation method of flame-retardant thermally conductive coating comprises the following steps:

[0032] (1) Add the flame-retardant heat-conducting powder into the synthetic resin and stir, the stirring speed is 1500-2000r / min, the temperature is 20-30°C, and the stirring time is 25-35min;

[0033] (2) Then add solvent and additives to stir and disperse, the stirring speed is 800-1000r / min, the temperature is 20-30°C, and the stirring time is 25-35min, to obtain a thermally conductive coating.

[0034]The flame-retardant and heat-conducting coating of the present invention uses boehmite flame retardant as heat-conducting powder, makes full use of its smoke suppression, flame-retardant, and heat-conducting properties, and adopts granulation technology to develop towards superfineness, and reasonably selects particle size distribution , to make full contact between particles and increase the density of particles. Durin...

Embodiment 1

[0037] A kind of flame-retardant heat-conducting paint, is made up of the raw material of following percentage by weight:

[0038] Boehmite flame retardant 6um 30wt%;

[0039] Synthetic resin: TDI modified alkyd resin 29wt%;

[0040] Solvent: ethyl acetate 20wt%, butyl acetate 20wt%;

[0041] Auxiliaries: 0.3 wt% of organic bentonite, 0.3 wt% of polyether modified siloxane solution, 0.4 wt% of cobalt isooctanoate.

[0042] The preparation method of flame-retardant heat-conducting coating in the present embodiment is:

[0043] (1) Add the flame-retardant and heat-conducting powder into the synthetic resin and stir, the stirring speed is 1500r / min, the temperature is 25°C, and the stirring time is 30min;

[0044] (2) Then add solvent and additives and stir to disperse. The stirring speed is 800r / min, the temperature is 25°C, and the stirring time is 30min to obtain a thermally conductive coating.

Embodiment 2

[0046] A kind of flame-retardant heat-conducting paint, is made up of the raw material of following percentage by weight:

[0047] Boehmite flame retardant 6um 40wt%;

[0048] Synthetic resin: acrylic resin 29wt%;

[0049] Solvent: ethyl acetate 30wt%;

[0050] Auxiliaries: 0.3 wt% of organic bentonite, 0.3 wt% of polyether modified siloxane solution, 0.4 wt% of cobalt isooctanoate.

[0051] The preparation method of flame-retardant heat-conducting coating in the present embodiment is:

[0052] (1) Add the flame-retardant heat-conducting powder into the synthetic resin and stir, the stirring speed is 2000r / min, the temperature is 20°C, and the stirring time is 30min;

[0053] (2) Then add solvent and additives and stir to disperse. The stirring speed is 1000r / min, the temperature is 20°C, and the stirring time is 30min to obtain a thermally conductive coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com