A kind of ultra-low surface energy polyethylene protective film and preparation method thereof

A polyethylene protective film and low-density polyethylene technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of prolonging the production cycle of products, unfavorable industrial production, and decreased product adhesion, and achieve effective Facilitate unwinding and unwinding, maintain ultra-low surface energy, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

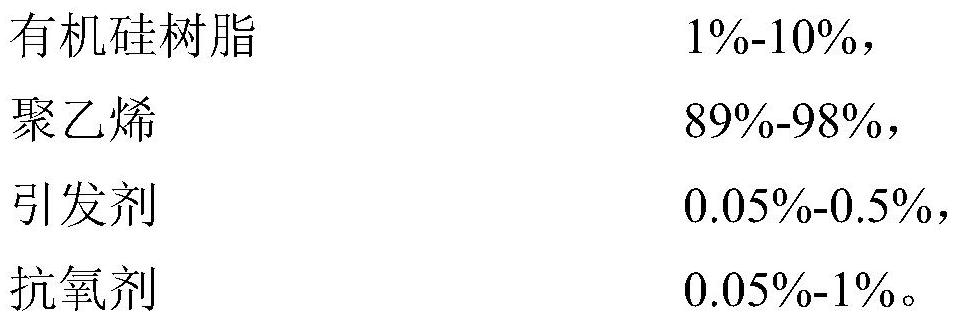

Method used

Image

Examples

Embodiment 1

[0041] A polyethylene protective film with ultra-low surface energy comprises a glue coating layer, a base film layer, an intermediate layer and an anti-adhesive layer which are sequentially laminated. The polyethylene protective film is prepared by the following method:

[0042] (1) Preparation of modified masterbatch: 5 kg of vinyltriethoxysilane, 93 kg of low-density polyethylene, 1 kg of linear low-density polyethylene, 0.5 kg of 1,3-di-tert-butylperoxide diisopropyl Put benzene and 0.5kg of diaryl secondary amine into the mixer and mix at high speed for 10 minutes, then place it in a twin-screw extruder, the temperature of each section of the screw is 170-190°C, melt and mix evenly, extrude, and cool to room temperature Finally, it is granulated by a granulator and dried to obtain a modified masterbatch.

[0043] (2) Preparation of polyethylene protective film: After mixing the raw materials of base film layer, middle layer and anti-adhesive layer respectively, they are r...

Embodiment 2

[0048] A polyethylene protective film with ultra-low surface energy comprises a glue coating layer, a base film layer, an intermediate layer and an anti-adhesive layer which are sequentially laminated. The polyethylene protective film is prepared by the following method:

[0049] (1) Preparation of modified masterbatch: 4 kg of vinyltrimethoxysilane, 95 kg of low-density polyethylene, 0.2 kg of dicumyl peroxide, and 0.8 kg of p-phenylenediamine were put into the mixer and mixed at high speed for 15 minutes. Then put it in a twin-screw extruder, the temperature of each section of the screw is 170-190°C, and extrude after melting and mixing evenly, after cooling to room temperature, granulate through a granulator, and dry to obtain a modified masterbatch .

[0050] (2) Preparation of polyethylene protective film: After mixing the raw materials of base film layer, middle layer and anti-adhesive layer respectively, they are respectively placed in three extruders, plasticized and ext...

Embodiment 3

[0055] A polyethylene protective film with ultra-low surface energy comprises a glue coating layer, a base film layer, an intermediate layer and an anti-adhesive layer which are sequentially laminated. The polyethylene protective film is prepared by the following method:

[0056] (1) Preparation of modified masterbatch: 2 kilograms of vinyl tris (2-methoxyethoxy) silane, 4 kilograms of 3-(methacryloxy) propyl trimethoxysilane, 93 kilograms of low density polyethylene, 0.1 kg of di-tert-butane peroxide and 0.9 kg of dilauryl thiodipropionate were put into the mixer and mixed at high speed for 12 minutes, and then placed in a twin-screw extruder. The temperature of each section of the screw was 170-190 ° C. After Melt and mix uniformly, extrude, cool to room temperature, granulate through a granulator, and dry to obtain the modified masterbatch.

[0057] (2) Preparation of polyethylene protective film: After mixing the raw materials of base film layer, middle layer and anti-adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com