A kind of preparation method of high tungsten and high cobalt nickel alloy fine-grained sheet material

A nickel alloy and high-cobalt technology, applied in the field of metal material manufacturing, can solve problems such as high strength and deformation hardening index, narrow thermal processing temperature range, complex process, etc., and achieve low equipment capacity requirements, good performance consistency, and stable process good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

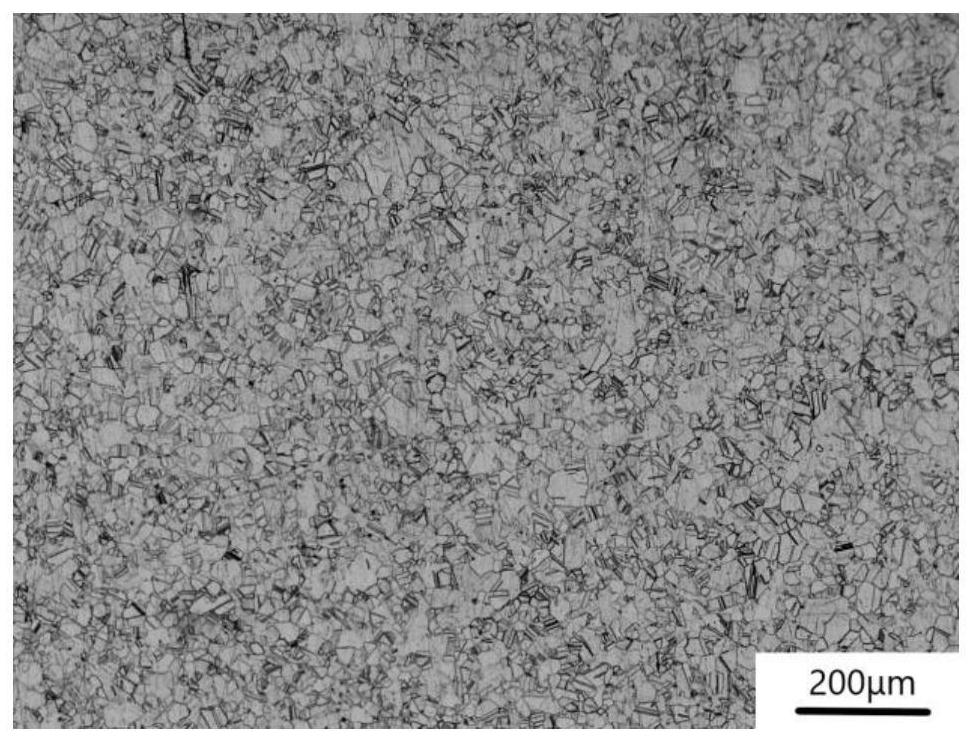

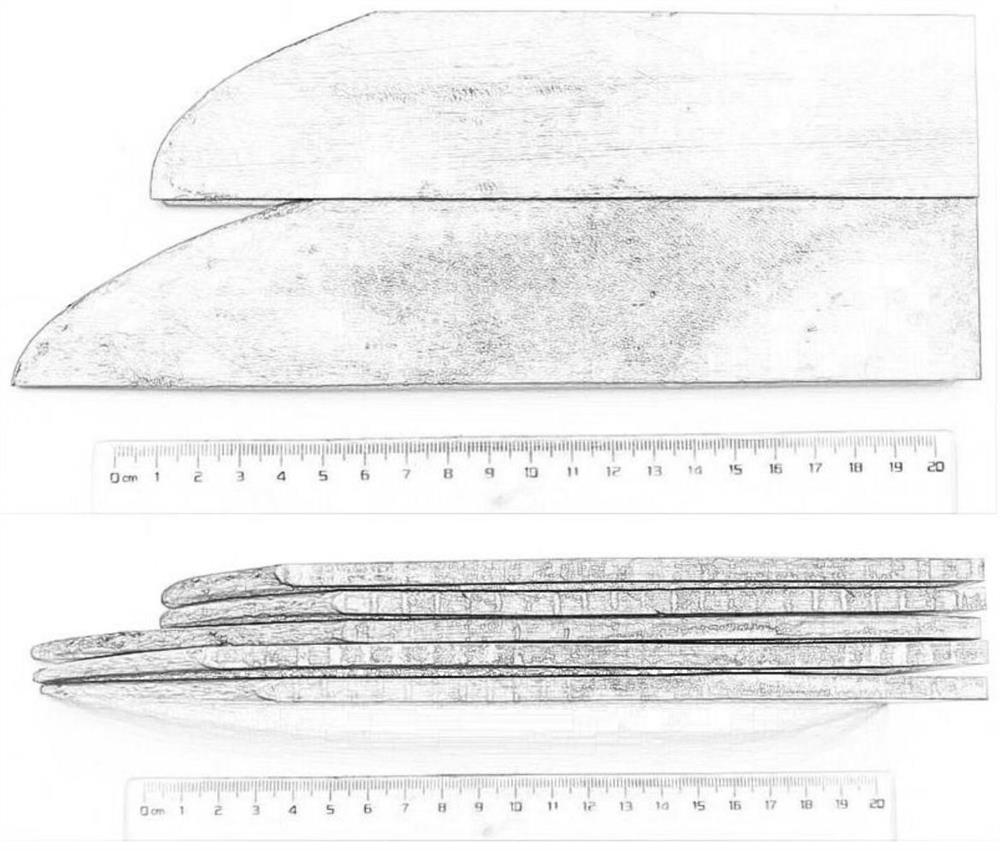

[0029] 1) An exemplary high-tungsten and high-cobalt nickel alloy contains, by mass percentage: 37% tungsten, 19% cobalt and the balance nickel.

[0030] 2) According to the element ratio of the alloy described in step 1), the raw materials are weighed, including metal tungsten bars, metal cobalt plates and metal nickel plates, melted in a vacuum induction furnace, and cast into 25 kg ingots.

[0031] 3) Heating the high-tungsten and high-cobalt nickel alloy ingot obtained in step 2) in a heating furnace, the heating temperature is 1200° C., and the holding time is 2 hours, and then forging is carried out, and the deforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com