A method of rotary friction welding of dissimilar metals

A technology of rotational friction welding and dissimilar metals, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of high equipment requirements, low joint welding quality, huge difference in metal melting point and high temperature mechanical properties, etc., to achieve The pressure value is reduced, the plastic deformation is reduced, and the welding quality is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

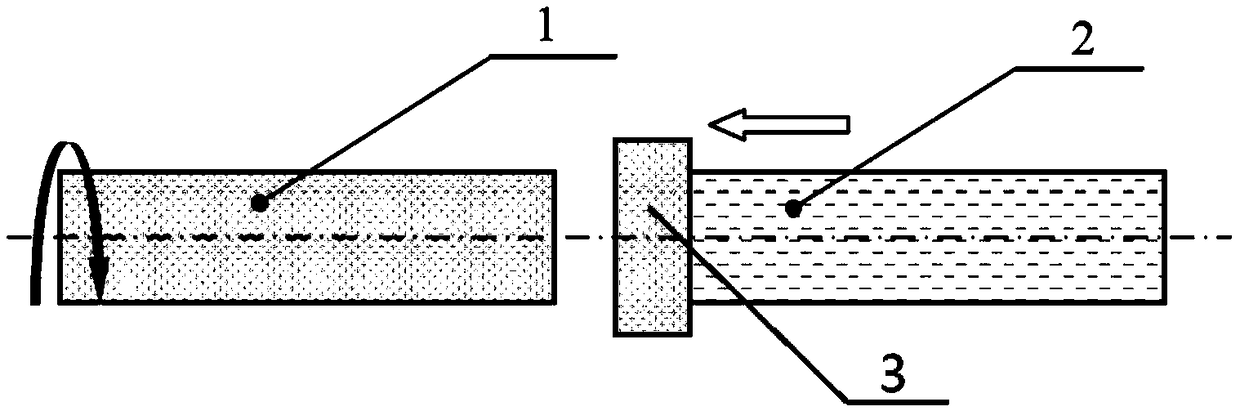

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of TA2 pure titanium and 45# steel rotational friction welding method, its specific process comprises the following steps:

[0045] Step 1, prepare the 45# steel ladle structure, and the threaded structure on one side of the TA2 titanium rod to be welded; select the 45# steel bar with a diameter greater than 2mm of the steel rod to be welded, and process it into a length of 10mm, with an internal thread size of A sheath structure with a height of 0.5mm, a pitch of 1mm, an inner diameter equal to the diameter of the bar to be welded, and a depth of 9mm.

[0046] And each surface to be welded is machined to a roughness Ra≤3.2μm, and then the oil and impurities are removed by acetone ultrasonic cleaning to obtain a sheath structure; one end of the titanium alloy to be welded is processed into a threaded structure that is tightly matched with the sheath structure, and the thread The overall length is 9.5mm.

[0047] Step 2, assemble the structural join...

Embodiment 2

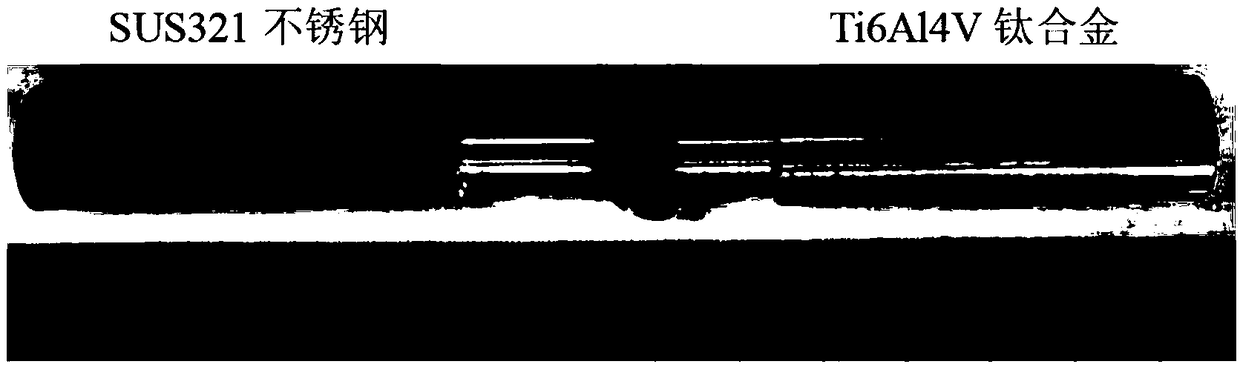

[0050] Embodiment 2, a kind of rotational friction welding method of TC4 titanium alloy and 1Cr18Ni9Ti stainless steel, its concrete process comprises the following steps:

[0051] Step 1, prepare the 1Cr18Ni9Ti stainless steel sheath structure, and the threaded structure on one side of the TC4 titanium alloy rod to be welded; select the 1Cr18Ni9Ti stainless steel rod with a diameter greater than 4mm of the steel rod to be welded, and process it into a length of 12mm, with an internal thread size of 1mm high, 1mm pitch, inner diameter equal to the diameter of the bar to be welded, and a sheath structure with a depth of 10mm.

[0052] And each surface to be welded is machined to a roughness Ra≤3.2μm, and then the oil and impurities are removed by acetone ultrasonic cleaning to obtain a sheath structure; one end of the TC4 titanium alloy to be welded is processed into a threaded structure that is tightly matched with the sheath structure, The total thread length is 10.5mm.

[0...

Embodiment 3

[0056] Embodiment 3: a kind of rotational friction welding method of TC4 titanium alloy and 0Cr17Ni12Mo2 stainless steel, its concrete process comprises the following steps:

[0057] Step 1, prepare the 0Cr17Ni12Mo2 stainless steel sheath structure, and the threaded structure on one side of the TC4 titanium alloy rod to be welded; select the 1Cr18Ni9Ti stainless steel rod with a diameter greater than 3 mm of the steel rod to be welded, and process it into a length of 10 mm, with an internal thread size of A sheath structure with a height of 0.8mm, a pitch of 1mm, an inner diameter equal to the diameter of the bar to be welded, and a depth of 8.5mm.

[0058] And each surface to be welded is machined to a roughness Ra≤3.2μm, and then the oil and impurities are removed by acetone ultrasonic cleaning to obtain a sheath structure; one end of the TC4 titanium alloy to be welded is processed into a threaded structure that is tightly matched with the sheath structure, The total thread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com