Preparation method of titanium modified phenolic resin

A technology of phenolic resin and boron phenolic resin, which is applied in the field of preparation of titanium-modified phenolic resin, can solve the problems that it is difficult to form a uniform solution, must be sealed and stored, and the reaction is not easy to control, so as to save the preparation cost, suitable for storage, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0026] The ethanol solution of preparation example 1-boron phenolic resin

[0027] First suck 956g of molten phenol into the reactor by vacuum, add 210g of boric acid while stirring, slowly raise the temperature to 140°C at a rate of 0.4°C / min, then gradually raise the temperature to 164°C at a rate of 0.1°C / min, and then Gradually raise the temperature to 181°C at a rate of 0.1°C / min, control the column head temperature to not exceed 98°C, collect fractions, stop heating when the weight of the fraction reaches 0.2 times that of phenol, discard the fraction, and the remaining product in the reactor is boric acid phenol ester. Lower the temperature of the boric acid phenol ester to below 60°C; add 303g of paraformaldehyde twice, control the heating rate to 0.5°C / min, and slowly raise the temperature to above 110°C until the reaction system starts to boil and reflux; after reflux for 30 to 40 minutes, it begins to decrease Pressure dehydration. When the gel time of the reactio...

Embodiment 1

[0029] (1) At 20°C, add 13g of butyl titanate into 120g of acetylacetone under stirring, and continue stirring until a uniform mixed solution A1 is formed.

[0030](2) At 20°C, under stirring, the above-mentioned mixed solution A1 was added dropwise at a constant speed and slowly to 700g of ethanol solution of boron phenolic resin with a glue content of 60wt%; the rate of addition was 4.5ml / min; the stirring speed was 200r / min.

[0031] (3) After the dropwise addition, continue stirring at 20° C. for half an hour at a stirring speed of 200 r / min to obtain titanium-modified boron phenolic resin B1, which is an orange-red, transparent solution.

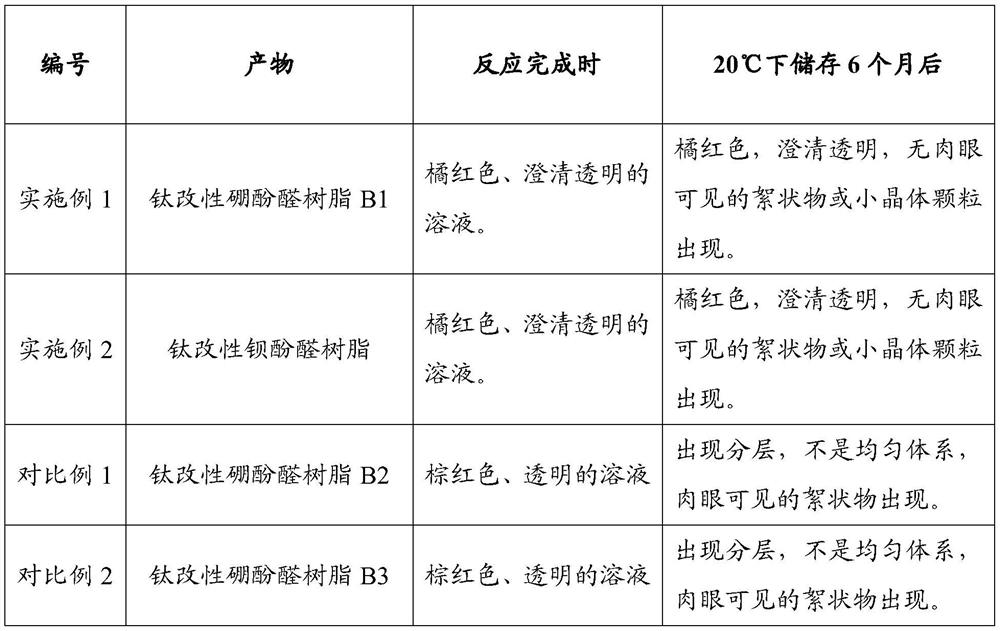

[0032] The mass retention rate at 800°C of the titanium-modified boron phenolic resin B1 in Example 1 was 70%. See Table 1 for the performance of storage stability of the titanium-modified boron phenolic resin B1 in Example 1.

Embodiment 2

[0034] (1) At 20° C., add 22 g of isopropyl titanate into 140 g of acetylacetone under stirring, and continue stirring until a uniform mixed liquid A2 is formed.

[0035] (2) at 20 DEG C, under stirring, the above-mentioned mixed solution A2 is added dropwise at a constant speed and slowly to the ethanol solution of 60wt% barium phenolic resin with a glue content of 700g; the rate of addition is 5.5ml / min; the stirring speed is 200r / min.

[0036] (3) After the dropwise addition, continue to stir at 20° C. for half an hour at a stirring speed of 200 r / min to obtain a titanium-modified barium phenolic resin, which is an orange-red, transparent solution.

[0037] See Table 1 for the performance of the storage stability of the titanium-modified barium phenolic resin in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com