Fishbone nanometer material as well as preparation and application thereof

A technology of nanomaterials and nanomesoporous materials, which is applied in the field of fishbone nanomaterials and its preparation and application, can solve the problems of unevenness, poor applicability, small pore size, etc., and achieve the effect of smooth surface and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment selects herring fish bone as raw material to carry out the following operations:

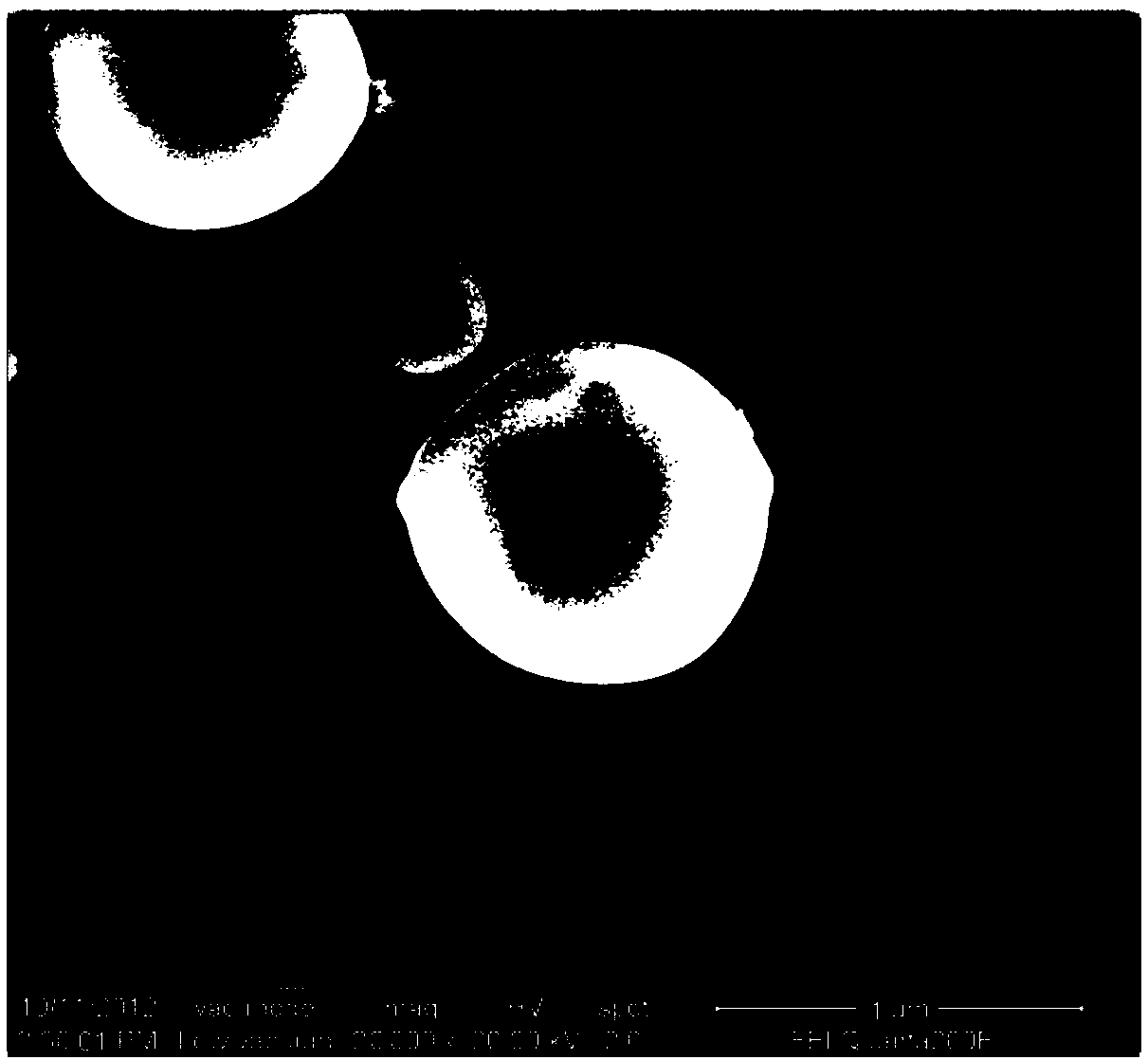

[0042] (1) Use petroleum ether to degrease the fish bones, first crush the fish bones for 10 minutes by ultrafine grinding at 15,000 rpm, then use a ball mill to grind the fish bones for 10 hours at a ball milling speed of 80 rpm, and pass through 800 mesh Sieve to obtain nano fishbone meal, the prepared fishbone meal is scanned by electron microscope, such as figure 1 shown;

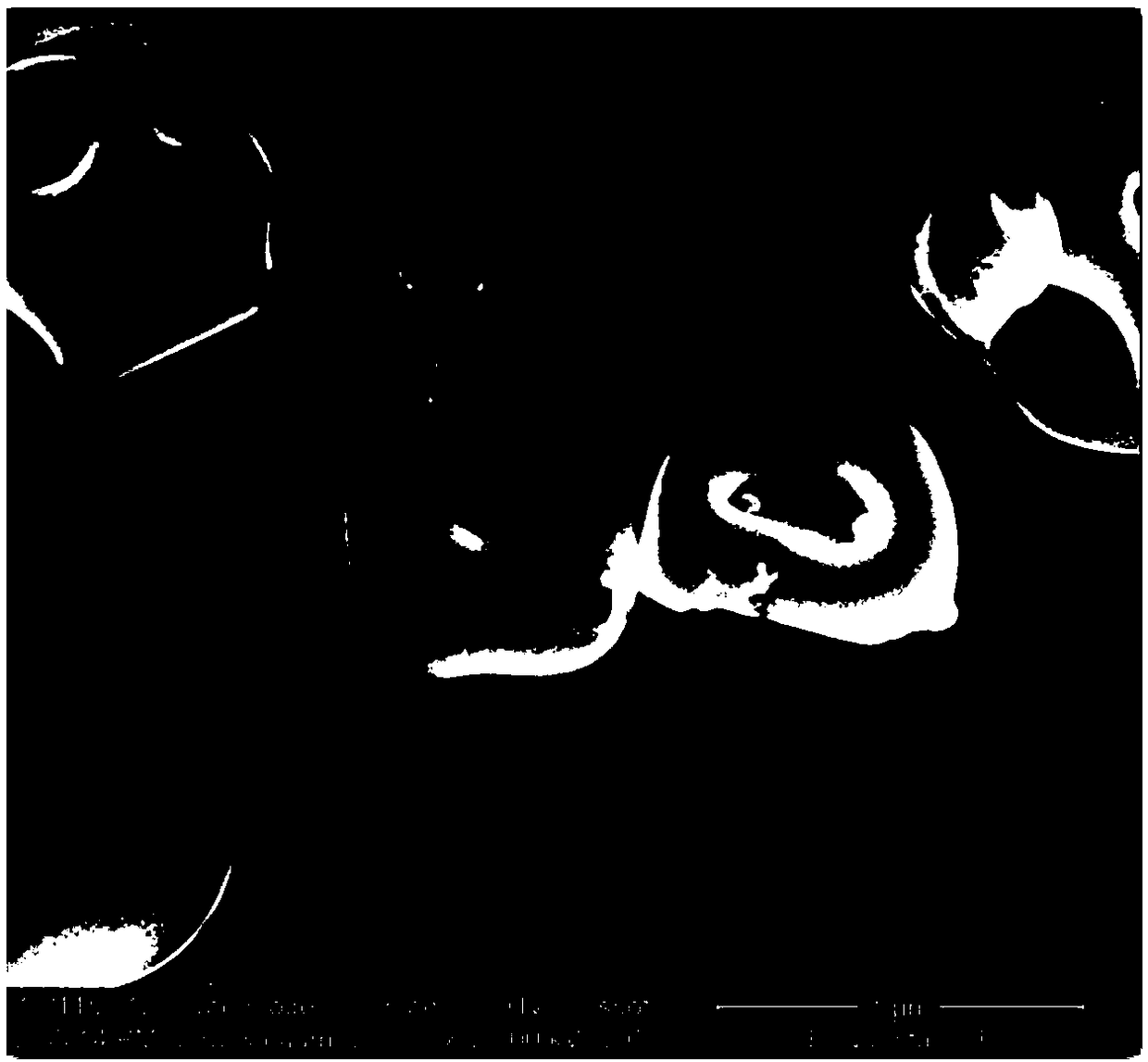

[0043](2) Dissolve 10g of nano-fishbone powder in water, add 3000U of hydrophobic compound flavor protease for enzymolysis, the reaction conditions are: pH value is 7.5, temperature is 45°C, reaction time is 1h, stirring continuously during the period to make it react Evenly, the fishbone nanomaterial A is prepared, and the prepared fishbone nanomaterial is scanned by electron microscope, such as image 3 shown.

Embodiment 2

[0045] The present embodiment selects grass carp bone as raw material to carry out the following operations:

[0046] (1) Use petroleum ether to degrease the fish bones, first crush the fish bones for 9 minutes by superfine grinding at 20,000 rpm, then use a ball mill to grind the fish bones for 6 hours with a ball milling speed of 80 rpm, and pass 1000 mesh sieve to obtain nano fishbone meal;

[0047] (2) Dissolve 10g of nano-fishbone powder in water, add 4000U of pepsin to carry out enzymolysis, the reaction conditions are: pH value is 8.0, temperature is 55°C, reaction time is 3h, stirring continuously during the period to make the reaction uniform, and prepare The fishbone nanomaterial B was obtained, and the prepared fishbone nanomaterial was scanned by an electron microscope.

Embodiment 3

[0049] The present embodiment selects silver carp fish bone as raw material to carry out the following operations:

[0050] (1) Degrease the fish bones with a mixed solvent of petroleum ether and ethanol with a volume ratio of 1:2. First, pulverize the fish bones for 8 minutes by ultrafine grinding at 15,000 rpm, and then use a ball mill with a ball milling speed of 100 rpm. The fish bone is pulverized for 9 hours per minute, and passed through a 800 mesh sieve to obtain nano fish bone powder;

[0051] (2) Dissolve 10g of nanometer fishbone meal in water, add 3500U of Bacillus subtilis alkaline protease for enzymolysis, the reaction conditions are: pH value is 8.5, temperature is 50°C, reaction time is 1.5h, during which it is constantly stirred to make it The reaction is uniform, and the fishbone nanomaterial C is prepared, and the prepared fishbone nanomaterial is scanned by an electron microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com