A kind of sustained-release sarafloxacin hydrochloride microcapsule and preparation method thereof

A technology of salafloxacin hydrochloride and microcapsules is applied in the directions of microcapsules, capsule delivery, pharmaceutical formulations, etc., and achieves the effects of simple preparation method, good palatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

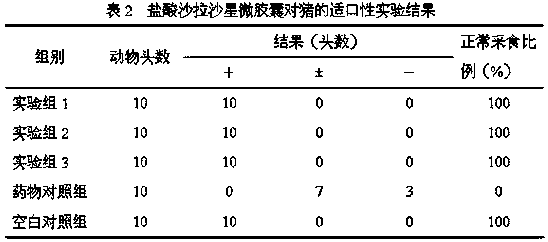

Examples

Embodiment 1

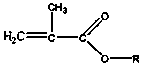

[0026] Add 40Kg of sarafloxacin hydrochloride to a 500L reactor, then add 400Kg of purified water and 5Kg of Span-80, and stir vigorously for 1 to 2 hours; keep stirring, add 8Kg of methyl methacrylate and 1Kg of allyl methacrylate in sequence Esters, 1Kg acrylic acid, and 0.1Kg benzoyl peroxide, heated up to 78°C for 3-4 hours, cooled the reaction product to room temperature, filtered, washed with water, and dried to obtain intestinal-targeted sustained-release sarafloxacin hydrochloride Microcapsule finished product.

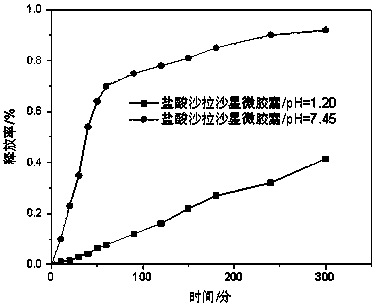

[0027] Take two portions of sarafloxacin hydrochloride microcapsule powder prepared above, each 0.100g, and put them into 100mL HCl solution simulated gastric juice (pH=1.20) and phosphate buffer solution simulated intestinal juice (pH=7.45) respectively, at (37±1 ) °C, stirred and released at a speed of 100 rpm for 3 hours, during which time 1mL solution was drawn from it at regular intervals, and the volume was fixed to 100mL with 0.1mol / L NaOH solution, and...

Embodiment 2

[0030] Add 50Kg of sarafloxacin hydrochloride to a 500L reaction kettle, then add 250Kg of purified water, 0.25Kg of Span-80, and stir vigorously for 1 to 2 hours; keep stirring, add 6Kg of methyl methacrylate, 1.3Kg of methacrylic acid in sequence Allyl ester, 1.5Kg acrylic acid, and 0.05Kg benzoyl peroxide, heated up to 78°C for 3-4 hours, cooled the reaction product to room temperature, filtered, washed with water, and dried to obtain intestinal-targeted slow-release hydrochloric acid The finished product of sarafloxacin microcapsules.

Embodiment 3

[0032] Add 30Kg sarafloxacin hydrochloride to a 500L reactor, then add 300Kg purified water, 10Kg Span-80, and stir vigorously for 1 to 2 hours; keep stirring, add 9Kg methyl methacrylate, 3Kg allyl methacrylate in turn Esters, 3Kg acrylic acid, and 0.3Kg benzoyl peroxide, heated up to 78°C for 3-4 hours, cooled the reaction product to room temperature, filtered, washed with water, and dried to obtain intestinal-targeted sustained-release sarafloxacin hydrochloride Microcapsule finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com