A method for preparing iron powder for reducing the content of acid-insoluble matter in iron raw materials

A technology of acid insoluble matter and iron powder, which is applied in furnaces, furnace types, cooking furnaces, etc., can solve problems such as cumbersome procedures and poor effect of acid insoluble matter mass fraction, and achieve good application prospects, low equipment capacity requirements, and improved purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

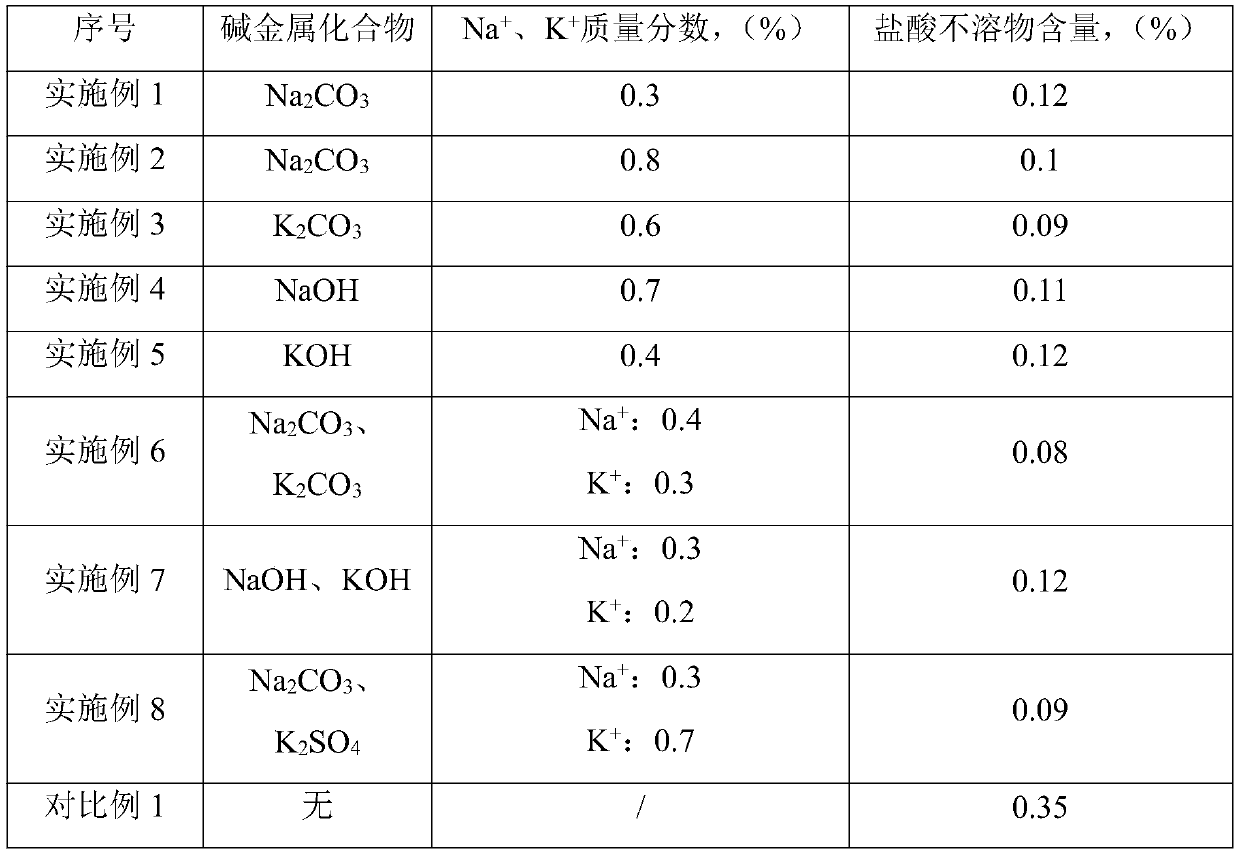

Embodiment 1-8

[0049] The present invention is implemented on a tunnel kiln with an annual output of 20,000 tons of primary iron powder. Embodiments 1-8 use partial reduction tanks for testing. The iron concentrate powder used has a total iron content of 71.3% and a hydrochloric acid insoluble content of 0.25%; Coal powder adopts anthracite pulverized coal, with an average particle size of 100 mesh to 200 mesh, a fixed carbon content of 74%, a volatile matter of 8%, and ash content of 12%. head. The temperature of the constant temperature section of the tunnel kiln is 1150°C, the time of the preheating section is 24 hours, the time of the constant temperature section is 24 hours, and the time of the cooling section is 24 hours. Mix a certain proportion of alkali metal compounds into the iron concentrate powder, and the sum of the mass fractions of Na ions and K ions is 0.3% to 1%; The charging method of the kiln is added to the reduction tank; the kiln constant temperature is 1150°C, the pr...

Embodiment 9

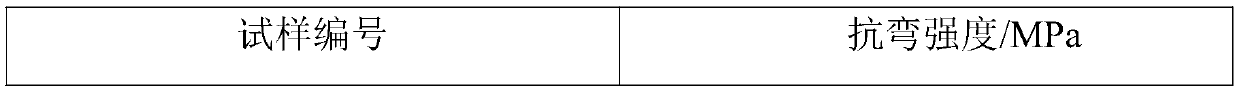

[0057] This embodiment provides an iron powder prepared by the method of the above-mentioned embodiment 3, which is sintered into a part after secondary reduction, and the bending strength of the part is 1040 MPa.

Embodiment 10

[0059] This embodiment provides an iron powder prepared by the method of the above-mentioned embodiment 6, which is sintered into a part after secondary reduction, and the bending strength of the part is 1080 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com