A kind of graphene-based antimony sulfide negative electrode material and its preparation method and application

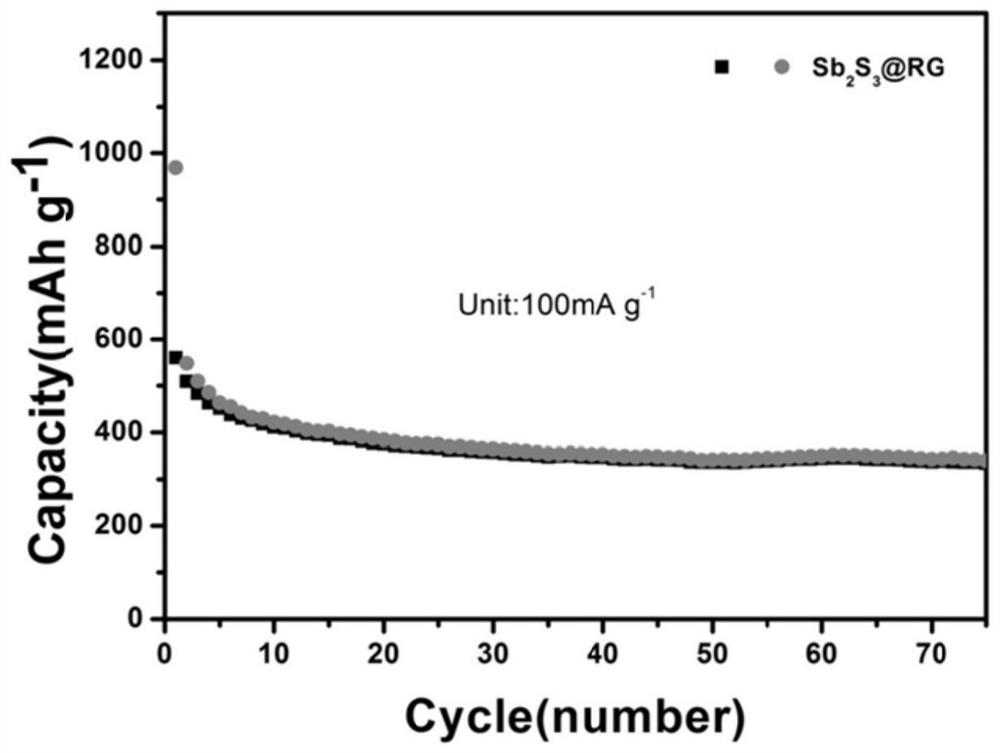

A technology of alkenyl antimony sulfide and negative electrode materials, which is applied in the field of electrochemistry, can solve problems such as deterioration of electrical integrity, capacity fading, film cracking, etc., and achieves the effect of good effect, low cost, simple and safe method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The first step, preparation of antimony sulfide material:

[0051] (1) 0.25g SbCl 3 Add it into 30mL deionized water and stir well; then add 30mL ethylene glycol into the above solution and stir for 10min;

[0052] (2) Then 0.3g sodium borohydride (NaBH 4 ) was slowly added into the solution and stirred evenly, and then 0.75 g of polyvinylpyrrolidone (PVP) with a molecular weight of 300,000 was added into the solution until fully dissolved;

[0053] (3) Finally, pour the solution into the lining of a hydrothermal kettle containing sulfur powder for hydrothermal heating at a temperature of 160-200° C. for 12-24 hours.

[0054] The second step is to prepare graphene-based antimony sulfide negative electrode material:

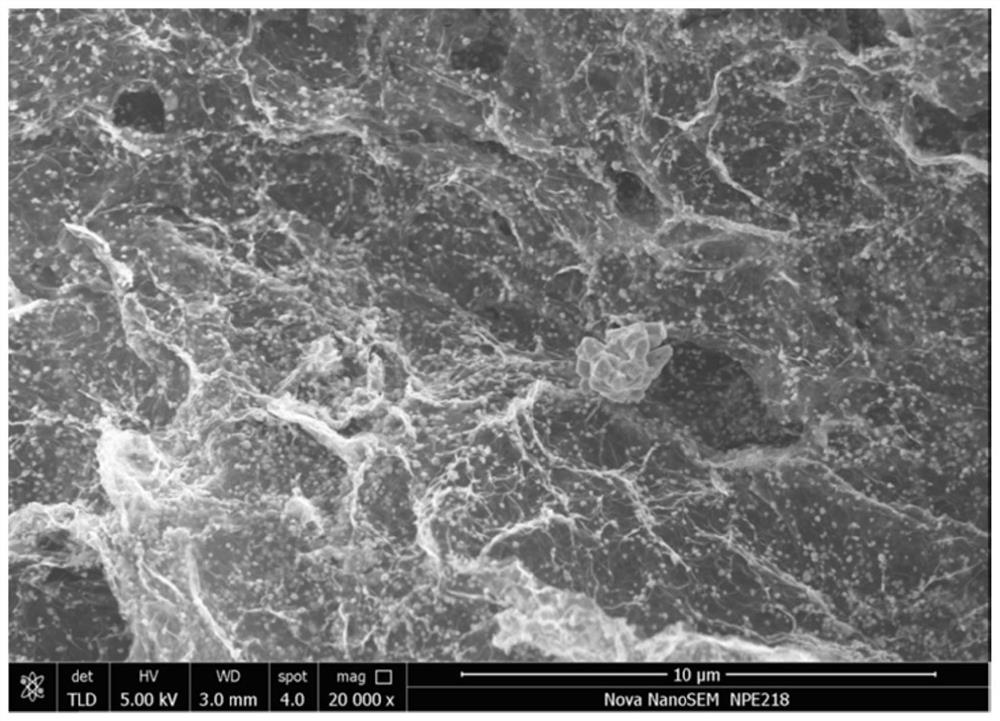

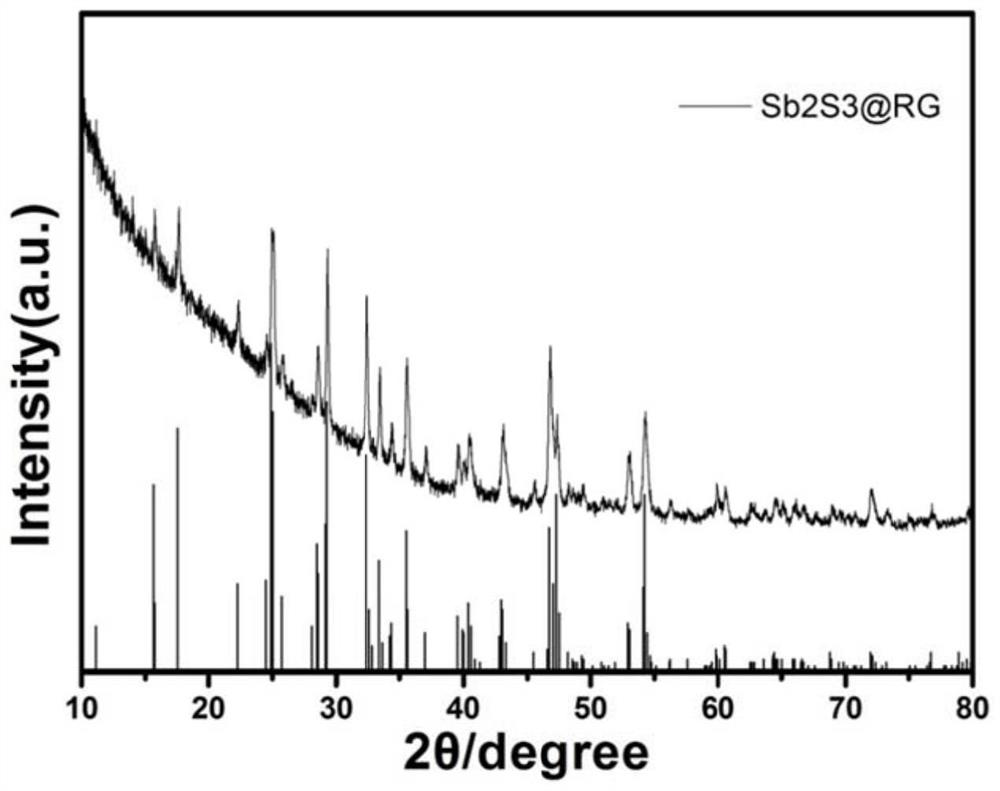

[0055] (1) After hydrothermal completion, the resulting solution was washed with deionized water and then dried to obtain Sb 2 S 3 , the resulting Sb 2 S 3 and GO again with hydrothermal 180 ℃, 12h to get Sb 2 S 3 @RG composite material, finally fr...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, except that in this embodiment, in the first step (1), the amount of deionized water added is 25 mL.

Embodiment 3

[0061] This example is basically the same as Example 1, except that in this example, in the first step (1), the amount of deionized water added is 35 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com