Ce-Zr bimetal cluster MOF-based oxygen reduction electrocatalyst and preparation method and application thereof

An electrocatalyst, bimetallic technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of increased oxygen vacancies, unfavorable reaction progress, etc., and achieves high oxygen reduction activity, easy control, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 37.5mg ZrOCl 2 ·8H 2 O, 5.6mg Ce(NO 3 ) 3 ·6H 2 Disperse O in 8 mL of DMF solution, add 474 mg of benzoic acid and 34 mg of meso-tetrakis(4-carboxyphenyl) porphine ferric chloride (Fe-TCPP), ultrasonicate at 25 °C for 10 min, react at 120 °C for 12 h, and filter with suction , washed until the filtrate was colorless, dried at 65 °C, and pyrolyzed at 700 °C for 1 h to finally obtain a black powder solid, which was recorded as 20% Ce-Zr-MOF electrocatalyst.

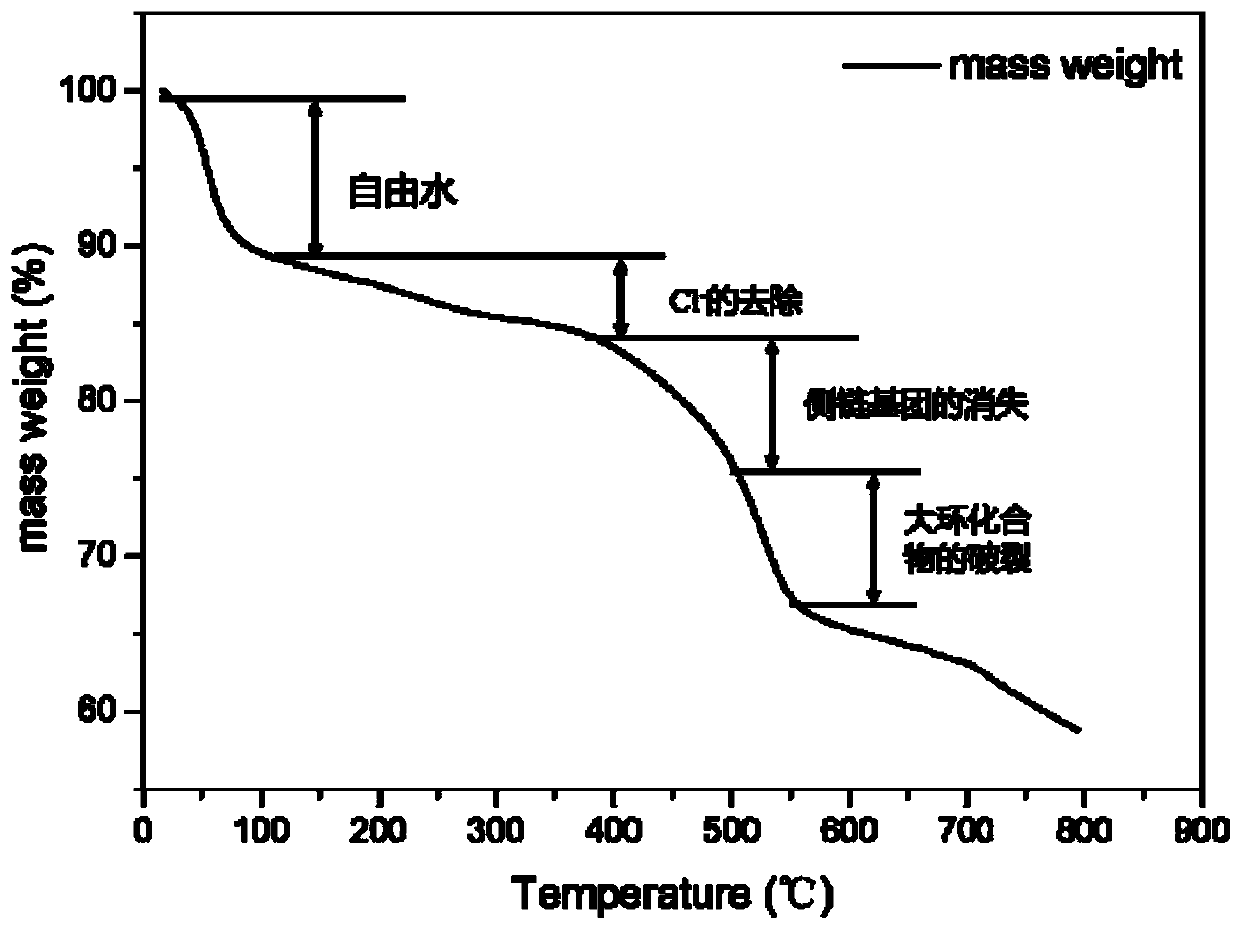

[0034] Such as figure 1 , thermogravimetric analysis shows that the Ce-Zr-MOF electrocatalyst in the present embodiment has better thermal stability, and the detailed description of its weight loss stage is as shown in the figure, and its weight loss stage is divided into five stages; loses free water stage ( 20°C-120°C); Cl - The loss stage (120°C-350°C); the loss stage of the side chain group of the macrocyclic compound (350°C-500°C); the fragmentation stage of the macrocycle compound (500°C-540°C); ).

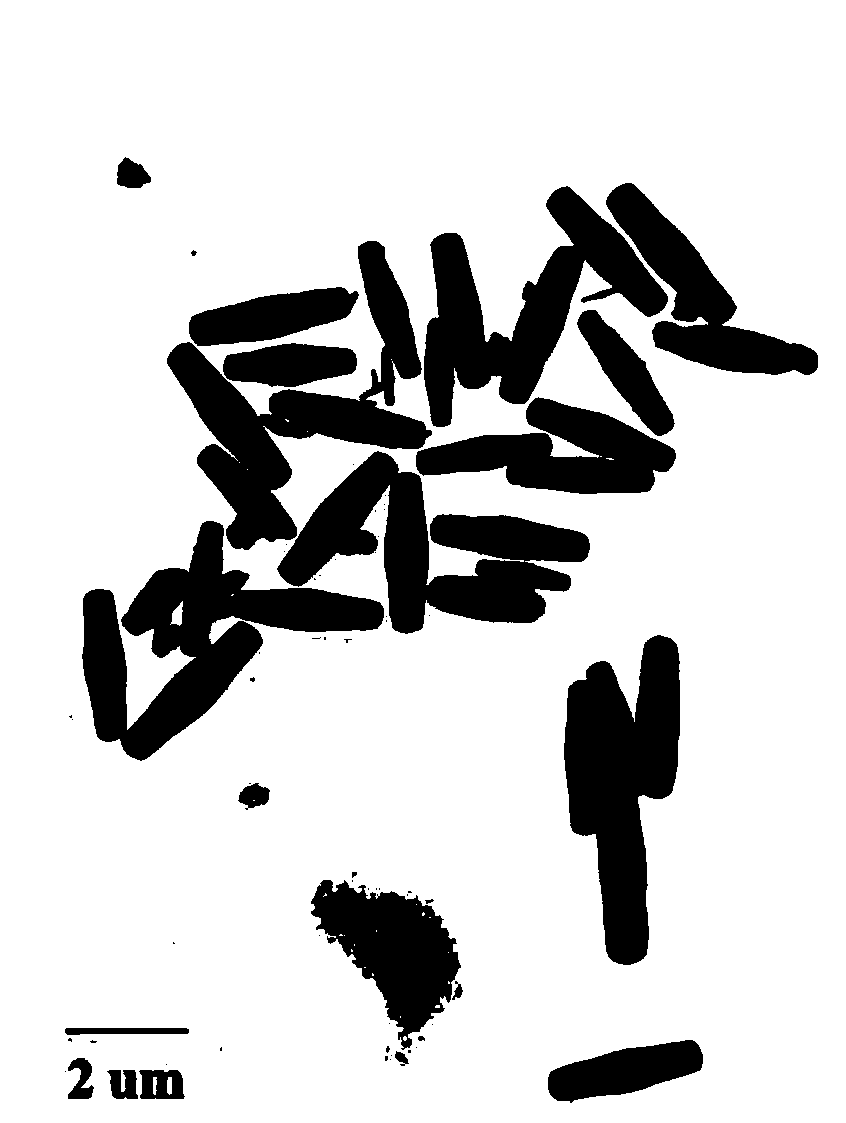

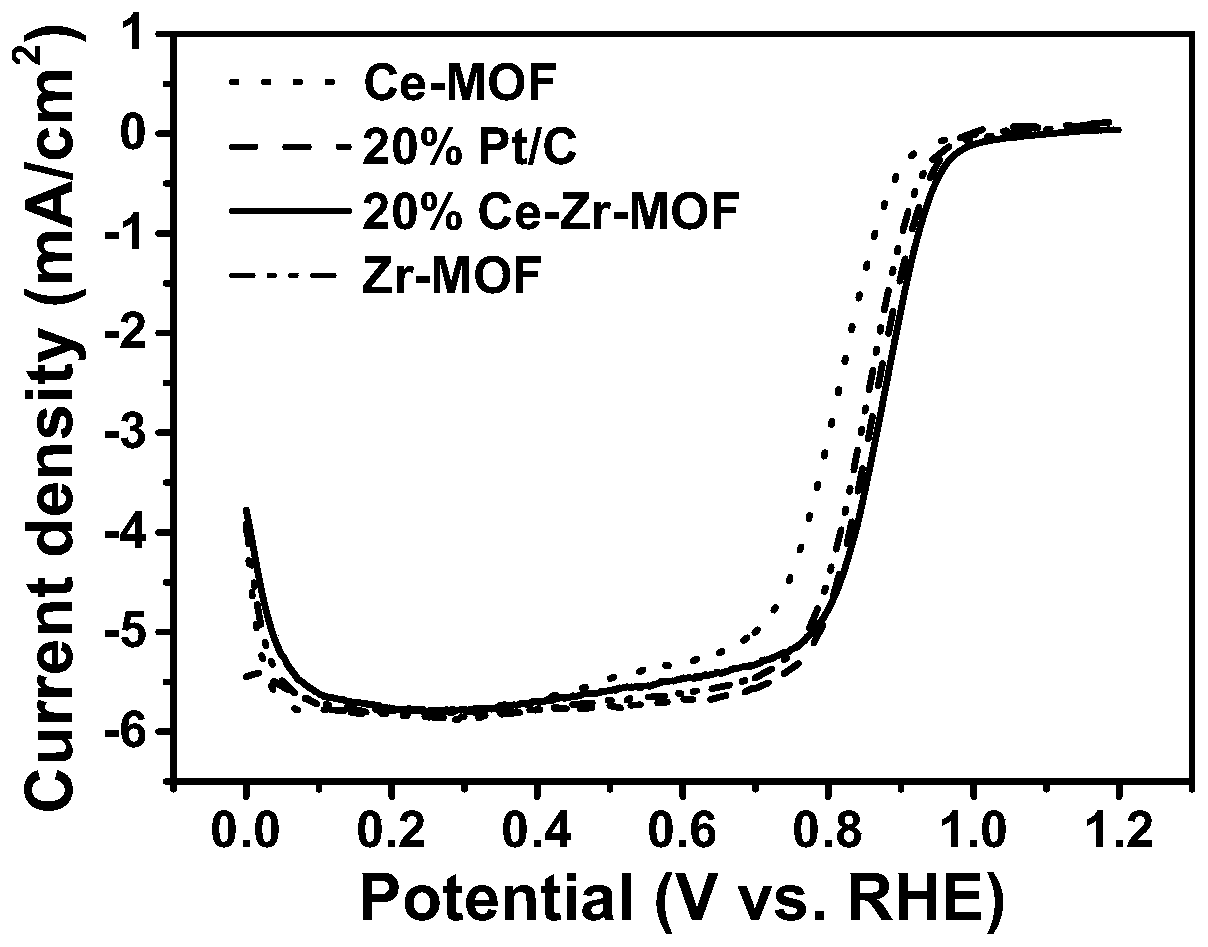

[0...

Embodiment 2

[0038] 39.5mg ZrOCl 2 ·8H 2 O, 2.8mg Ce(NO 3 ) 3 ·6H 2 Disperse O in 8 mL of DMF solution, add 474 mg of benzoic acid and 34 mg of meso-tetrakis(4-carboxyphenyl) porphine ferric chloride (Fe-TCPP), ultrasonicate at 25 °C for 10 min, react at 120 °C for 12 h, and filter with suction , washed until the filtrate was colorless, dried at 65°C, and pyrolyzed at 700°C for 1 hour to finally obtain a black powder solid. The morphology and performance of the catalyst obtained in Example 2 are similar to those of the sample in Example 1, and it has better overall oxygen reduction performance.

Embodiment 3

[0040] 33.5mg ZrOCl 2 ·8H 2 O, 11.2mg Ce(NO 3 ) 3 ·6H 2 Disperse O in 8 mL of DMF solution, add 474 mg of benzoic acid and 34 mg of meso-tetrakis(4-carboxyphenyl) porphine ferric chloride (Fe-TCPP), ultrasonicate at 25 °C for 10 min, react at 120 °C for 12 h, and filter with suction , washed until the filtrate was colorless, dried at 65°C, and pyrolyzed at 700°C for 1 hour to finally obtain a black powder solid. The morphology and performance of the catalyst obtained in Example 3 are similar to those of the sample in Example 1, and it has better overall oxygen reduction performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com