Low-energy flexible detonating cord

A flexible detonating cord, low-energy technology, applied in the directions of detonating cords, nitrated pentaerythritol compositions, etc., can solve the problem of large lateral detonation capability, interruption of propagation, affecting the reliability of the connection between the main line of the detonating cord and the side branch lines, etc. problems, to achieve the effect of reducing overall material consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

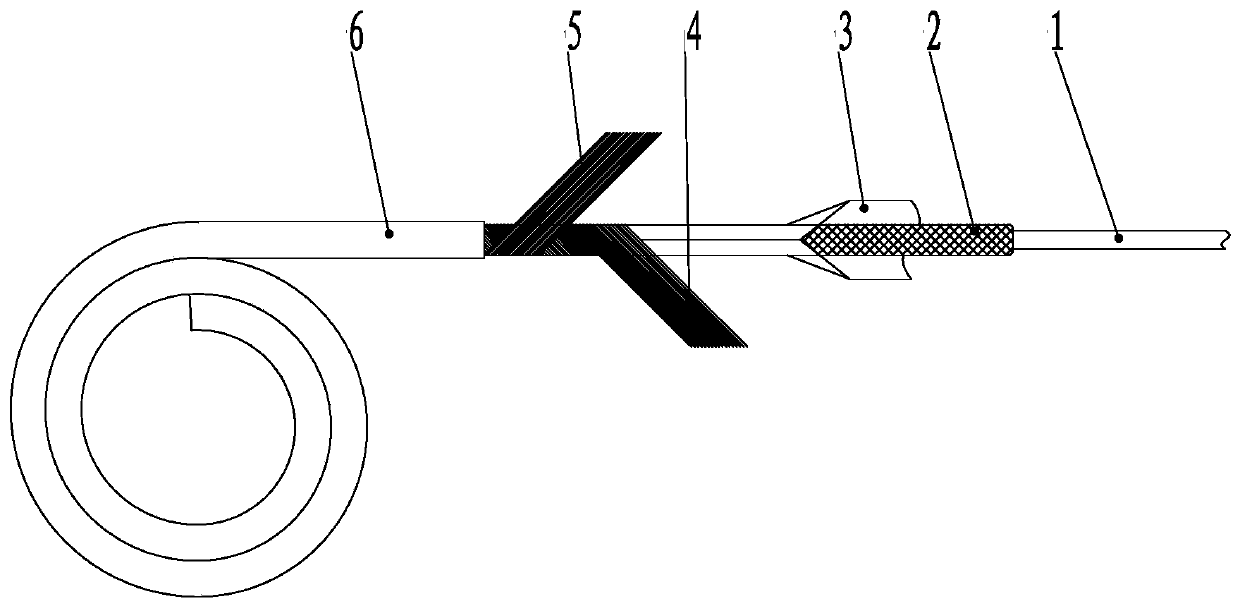

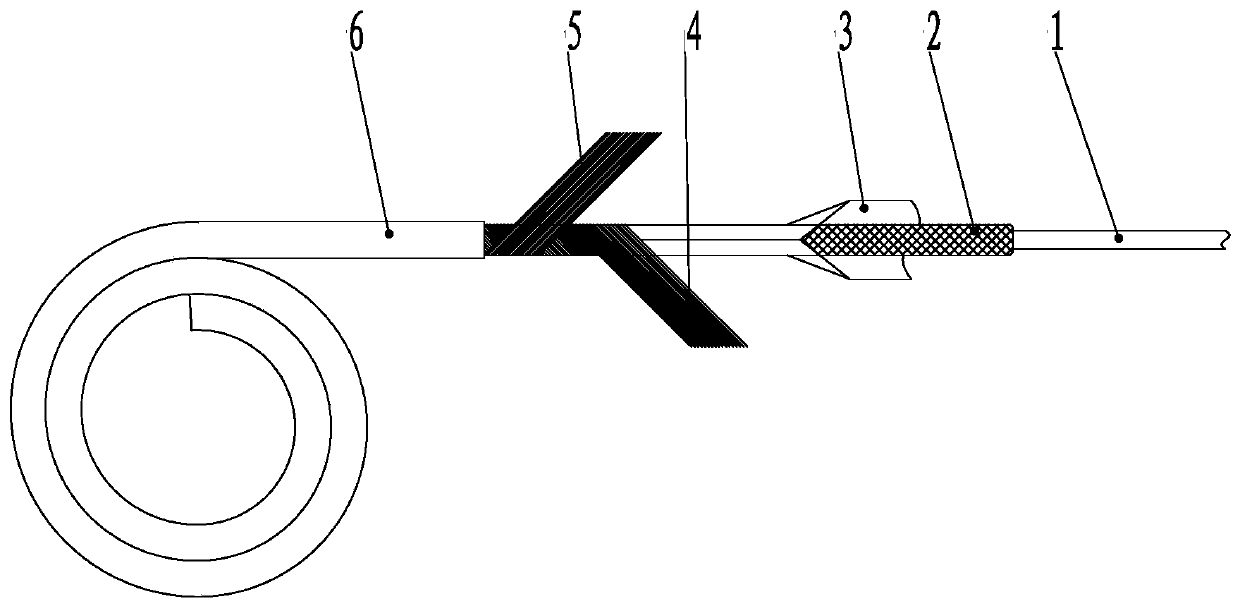

[0014] Example 1, the mass fraction of 85% ultra-fine Taian explosives with a particle size passing through a 30 mesh silk sieve flows to the center of the charging mold under the action of gravity, and flows into the inner mold evenly under the pulling of 4 core wires. In the injection hole, at the same time, under the constraint of the outer mold, the polyester film is curled from a strip into a trumpet shape, wrapping the explosives flowing out of the inner mold, ensuring that the amount of wrapped explosives is even in the film, thus forming explosives. drug core. On the surface of the explosive core wrapped by polyester film, the inner and outer layers of high-strength polyester filaments are reversely wound, so that the structure of the explosive core is evenly covered, and the explosive core is tightened and shaped to make the explosive core The packing density meets the design requirements to ensure that the detonating cord has a certain detonation performance and form...

Embodiment 2

[0015] Example 2, the mass fraction of 90% superfine Taian explosives with a particle size passing through a 30 mesh silk sieve flows to the center of the charging mold under the action of gravity, and flows into the inner mold evenly under the pulling of 3 core wires. In the injection hole, at the same time, under the constraint of the outer mold, the polyester film is curled from a strip into a trumpet shape, wrapping the explosives flowing out of the inner mold, ensuring that the amount of wrapped explosives is even in the film, thus forming explosives. drug core. On the surface of the explosive core wrapped by polyester film, the inner and outer layers of high-strength polyester filaments are reversely wound, so that the structure of the explosive core is evenly covered, and the explosive core is tightened and shaped to make the explosive core The packing density meets the design requirements to ensure that the detonating cord has a certain detonation performance and form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com