Diesel engine soot particle sampling device

A soot particle and sampling device technology, which is applied in sampling devices, measuring devices, particle and sedimentation analysis, etc., can solve the problems of low efficiency of classification process and single type of sampling particles, so as to increase the types and quantity of sampling and improve sampling efficiency. , Reduce the effect of particle size classification error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments do not limit the present invention in any way.

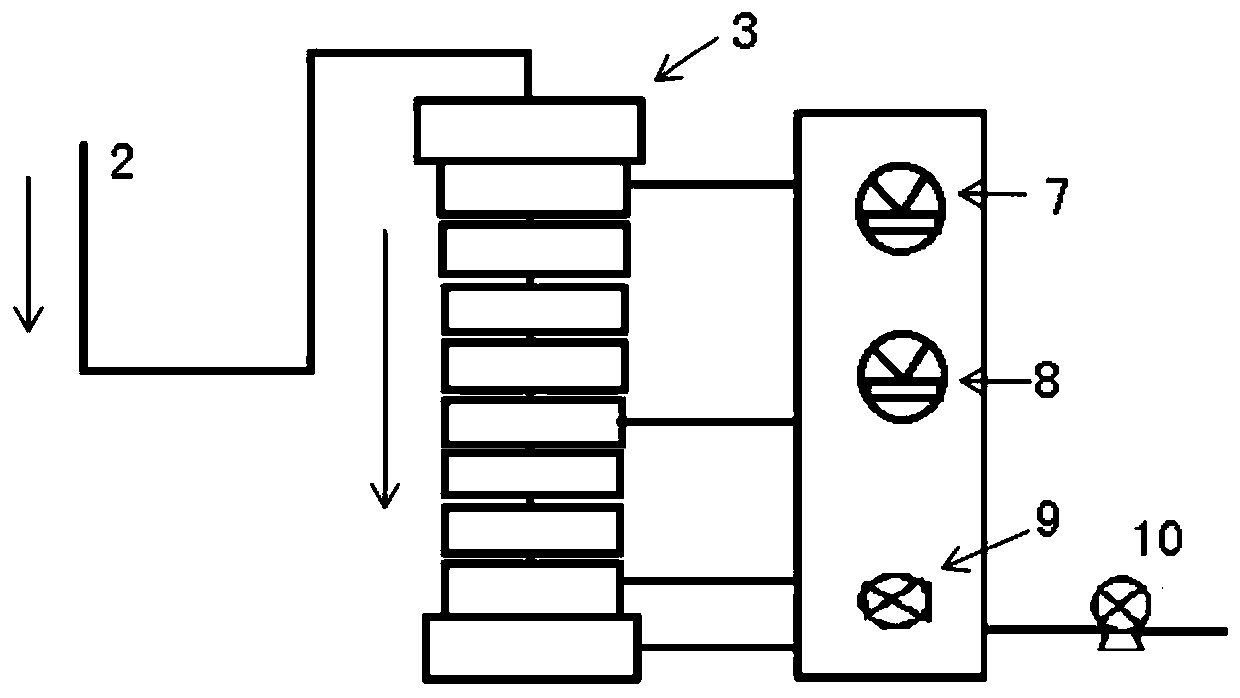

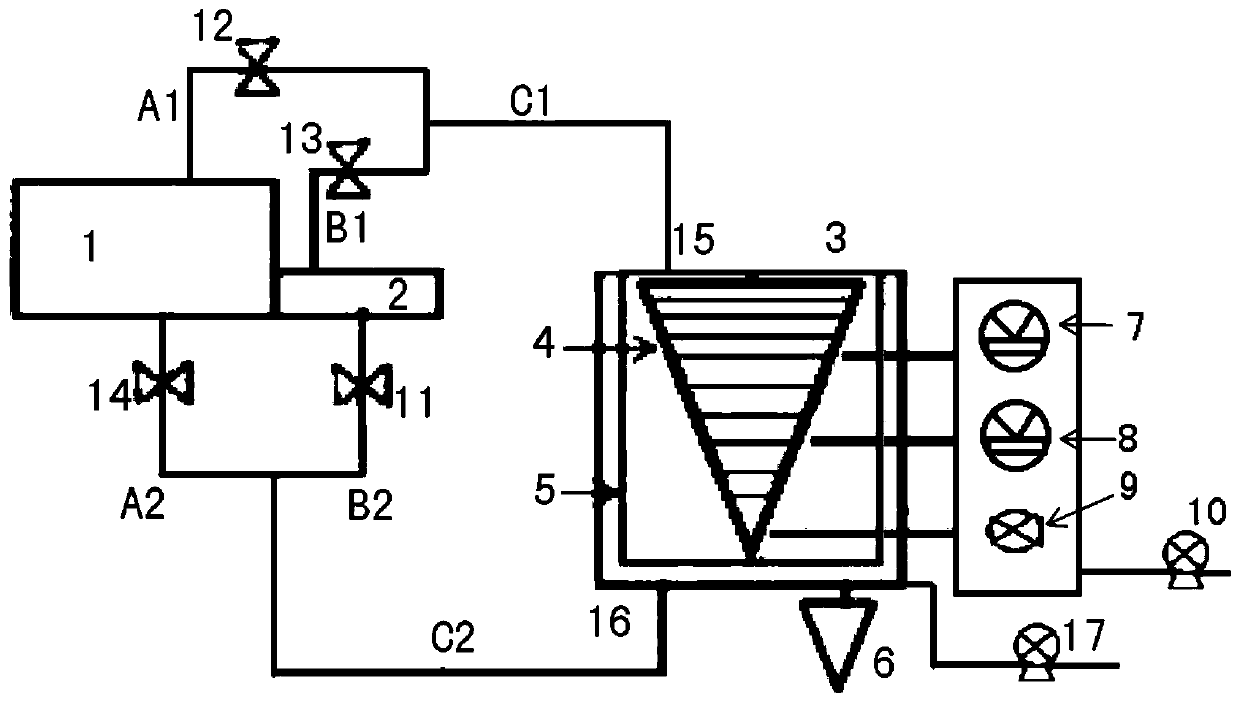

[0025] Such as figure 2 with Figure 4 As shown, a kind of diesel engine soot particle sampling device that the present invention proposes comprises sampling housing 3, and described sampling housing 3 is provided with pressure flow control device, and described pressure flow control device comprises upper differential pressure gauge 7, lower pressure Difference meter 8, flow meter 9 and air pump 10.

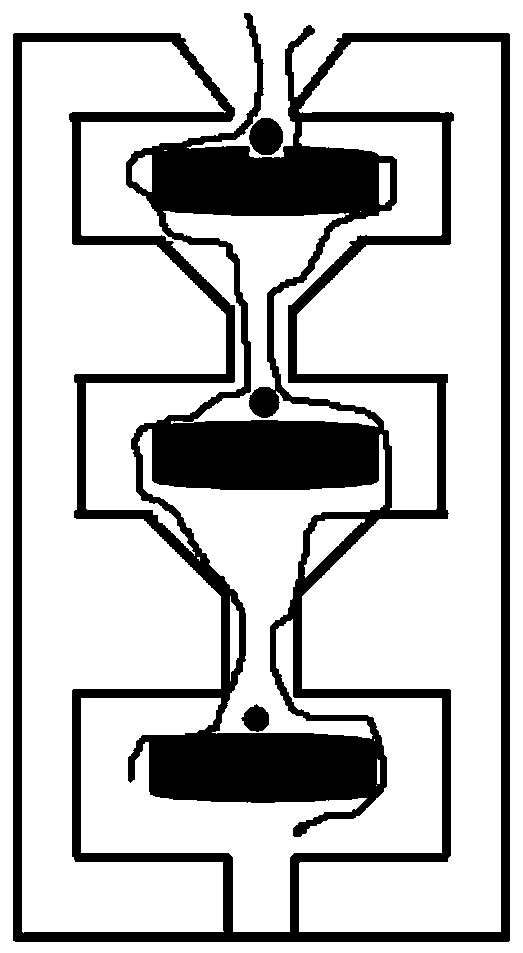

[0026] The sampling housing 3 is provided with a multi-stage particulate matter filter screen 4 from top to bottom, and the material of the particulate matter filter screen 4 is F1 coordinate copper mesh square film; during the collection process, usually on each layer of particulate matter filter screen The material will decrease from top to bottom. In order to save ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com