Hexagonal interlocked electrode three-dimensional silicon detector

A hexagonal and detector technology, used in circuits, electrical components, semiconductor devices, etc., can solve the problems of longer electron and hole movement time, slow movement of electrons and holes, and inability to deplete the voltage, and achieves high efficiency. Effects of charge collection performance, improved cell independence, and uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

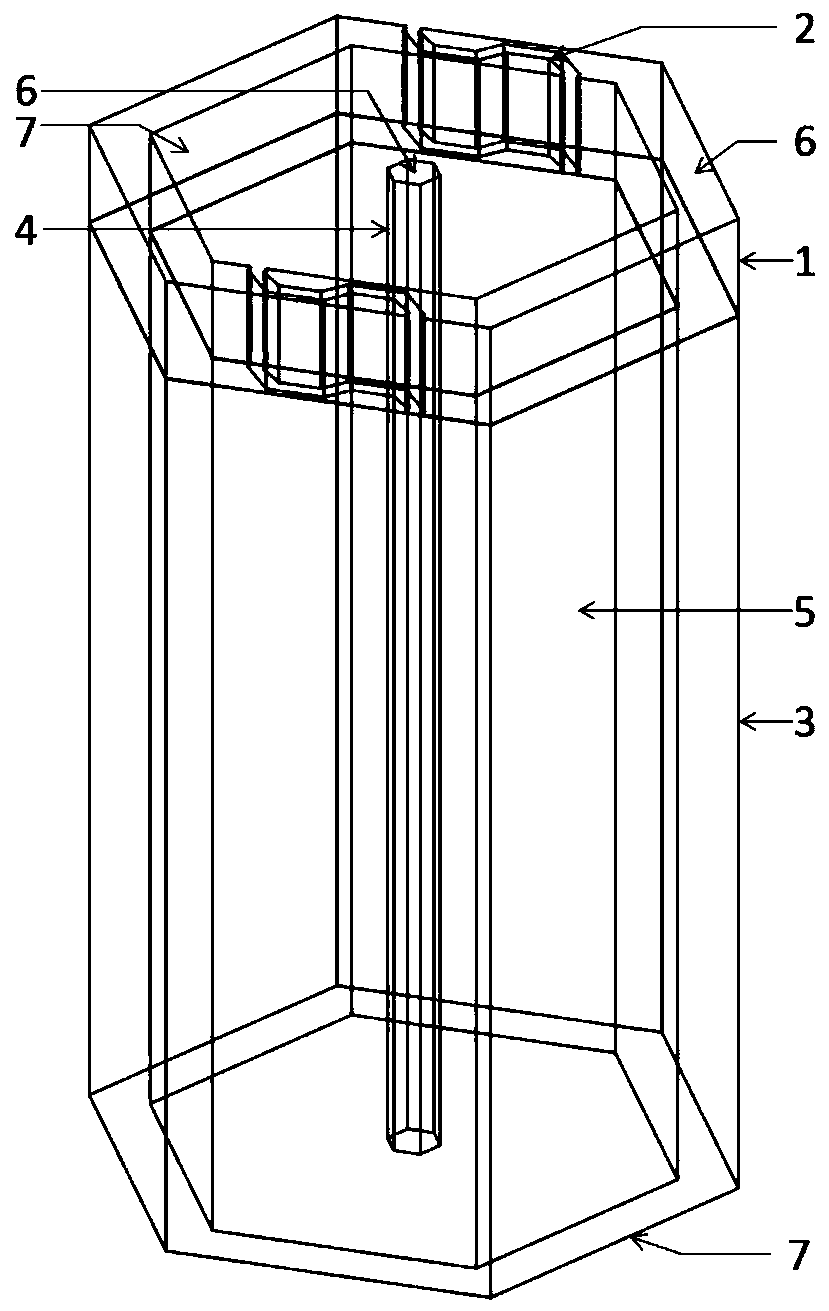

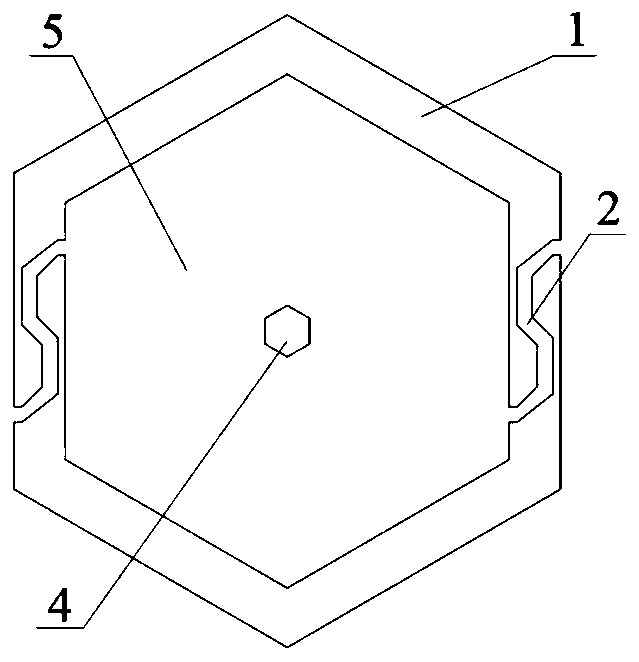

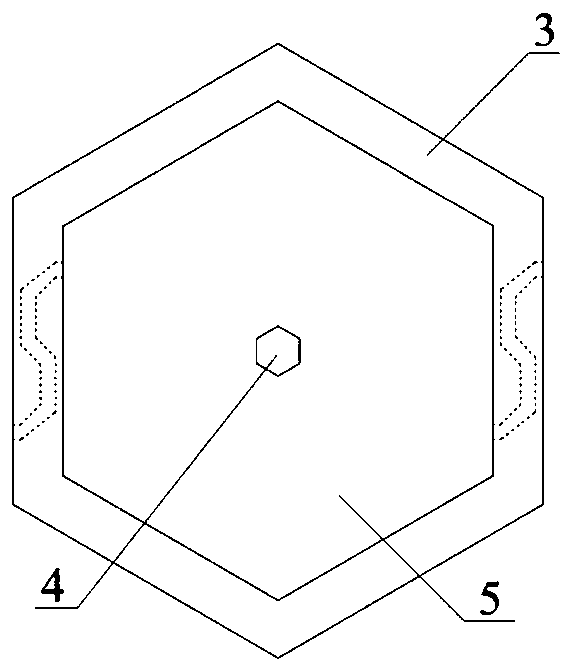

[0030] The structure of the hexagonal interlocking electrode silicon detector is as follows: Figure 1-Figure 3 As shown, it includes a hexagonal prism-shaped isolation silicon body 5, and the central axis of the isolation silicon body 5 is etched with a hexagonal prism from the top to the bottom surface, and the inner wall of the hexagonal prism is diffused and doped with boron and then filled with polysilicon to form a central electrode. 4. The six sides of the isolated silicon body 5 are etched with trenches, and the inner walls of the trenches are diffused and doped with phosphorus and filled with polysilicon to form the first trench electrode 1 and the second trench electrode 3, and isolate the silicon body 5 and the central electrode 4 , The bottom surface of the second trench electrode 3 is covered with a silicon dioxide protective layer 7, the top surface of the first trench electrode 1 and the center electrode 4 is covered with a metal contact layer 6, and the isolatio...

Embodiment 2

[0036] Modify the following dimensions of the silicon detector as follows: the height of the isolated silicon body 5 is 500 μm, the height of the first trench electrode 1 and the S-shaped isolated silicon body 2 is 50 μm, the height of the second trench electrode 3 is 450 μm, and the S-shaped The wall thickness of the isolated silicon body 2 is 4 μm, and other structures of the silicon detector are the same as those in the first embodiment.

[0037] Use the silicon detectors prepared in Examples 1 to 2 to detect incident particles. According to the test results, it can be known that enough carriers need to be excited after the incident particles enter the silicon detector, and can only be obtained when the influence of interface charges is small. Better electrical signal, if the height of the silicon detector is too small, the carriers generated by the incident particles will be easily affected by the charge on the upper and lower interfaces of the silicon detector, resulting i...

Embodiment 3

[0039] Without changing the size and position of each structure in the detection unit of Embodiment 1, only the gaps of the two C-shaped groove electrodes are set as a straight line through the center electrode 4, and the junction of the two C-shaped groove electrodes is assembled. A straight opening is left.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com