Process method for absorbing oil gas at low temperature

A process method, oil and gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of secondary pollution, wide gap, low oil and gas absorption efficiency, etc., achieve high absorption rate and prevent excessive emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

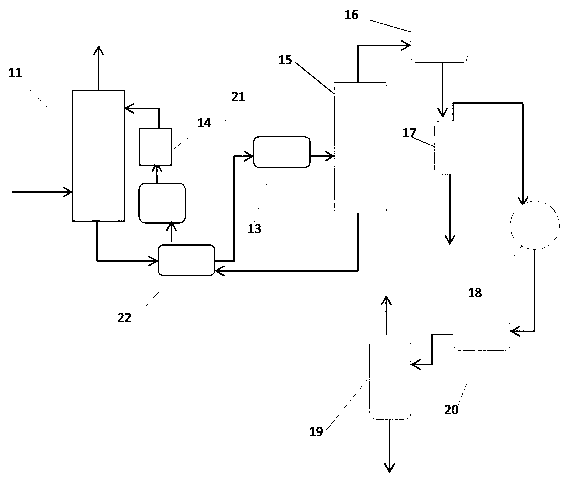

Method used

Image

Examples

Embodiment 1

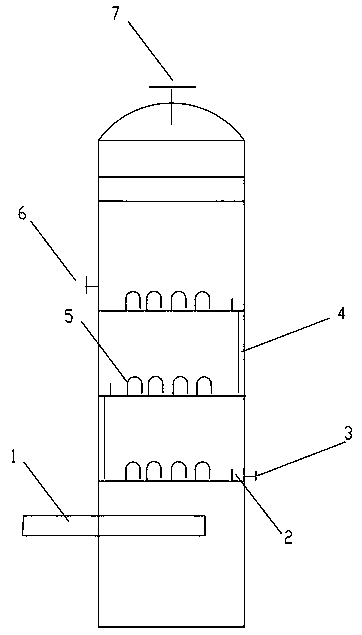

[0054] 2000m³ of oil and gas per hour needs to be processed. The diameter of the absorption tower is 1200mm, the number of trays is 10, the number of elbows on the tray is 500, each diameter is 20mm, the height of the overflow weir is 50mm, and the spacing between the trays 350mm, downcomer diameter 25mm.

[0055] Absorbent propylene glycol butyl ether, the flow rate in the absorption tower is 2000 liters / hour, the propylene glycol butyl ether storage tank is a vertical cylindrical storage tank of 3m³, there are 2.5 tons of propylene glycol butyl ether inside, and the refrigeration device adopts screw compressor refrigeration , The refrigerant is R404A, the evaporation temperature of the refrigerant is -40°C, and the evaporator of the refrigeration device is a tube-and-tube heat exchanger. After the propylene glycol butyl ether is cooled by the evaporator, the temperature is lowered to -25°C to absorb oil and gas.

[0056] The hot and cold fluid heat exchanger is a plate-and-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com