High-performance material optimal selection method suitable for space debris protection structure

A technology for protecting structures and space debris, which is applied in computer materials science, astronautical equipment, and spacecraft for astronautics. The effect of reducing trial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

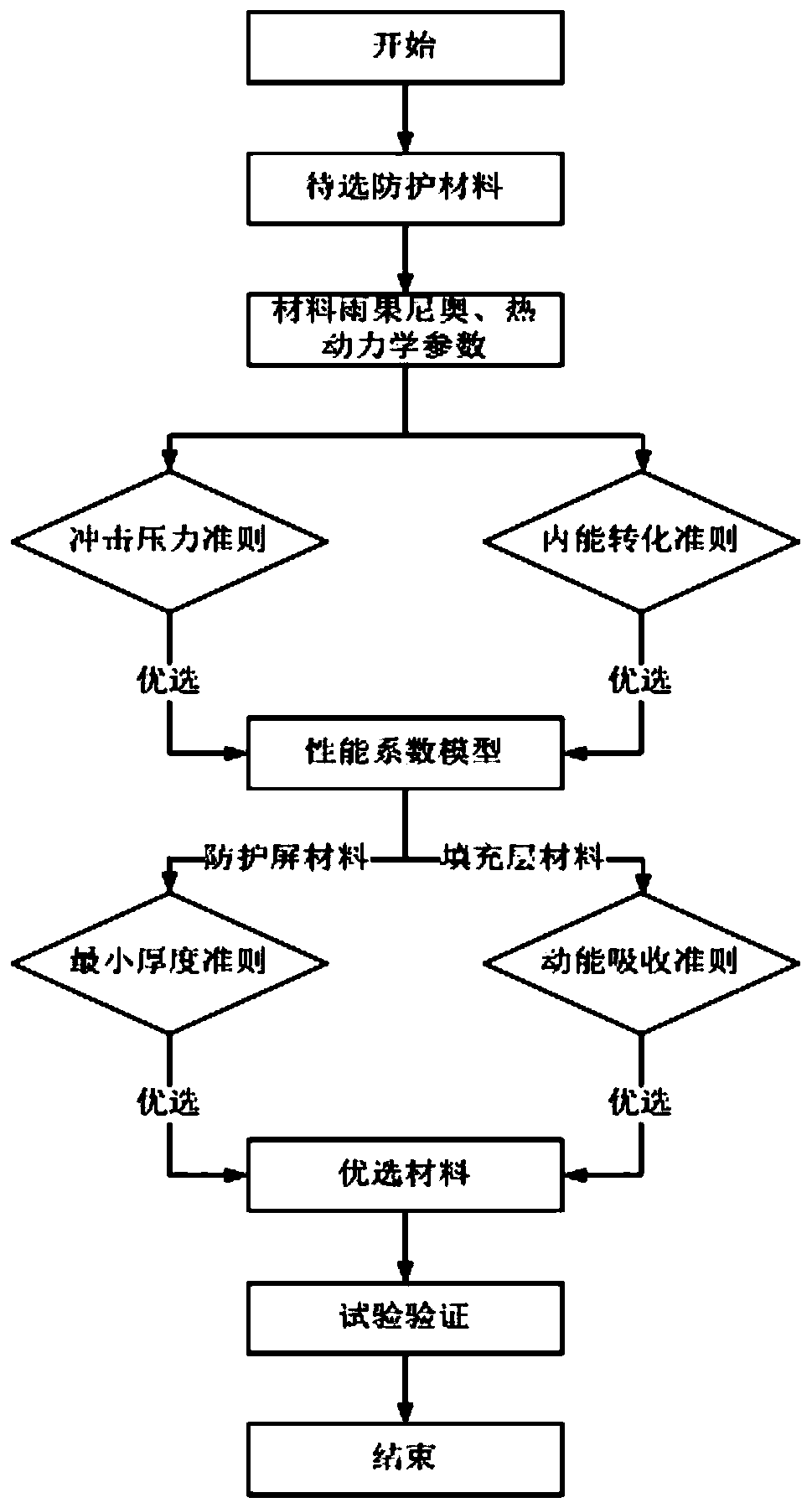

[0048] see Figure 1-5 , a method for optimizing high-performance materials suitable for space debris protection structures, comprising the following steps: a. selecting a protection material, and looking up a table to obtain the Hugo Neo and thermodynamic parameters of the material, b. according to the impact pressure criterion and Preliminary screening of protective materials based on internal energy conversion criteria, c. further optimization of protective materials through the coefficient of performance model, d. screening of protective screen materials according to the minimum thickness criterion, and optimal protective screen materials, e. filling according to the kinetic energy absorption criterion Layer material is screened to obtain the preferred filling layer material, f. the preferred protective screen material and filling layer material are tested and verified;

[0049]Impact pressure criterion: The impact pressure depends on the impact velocity, the density of th...

Embodiment 2

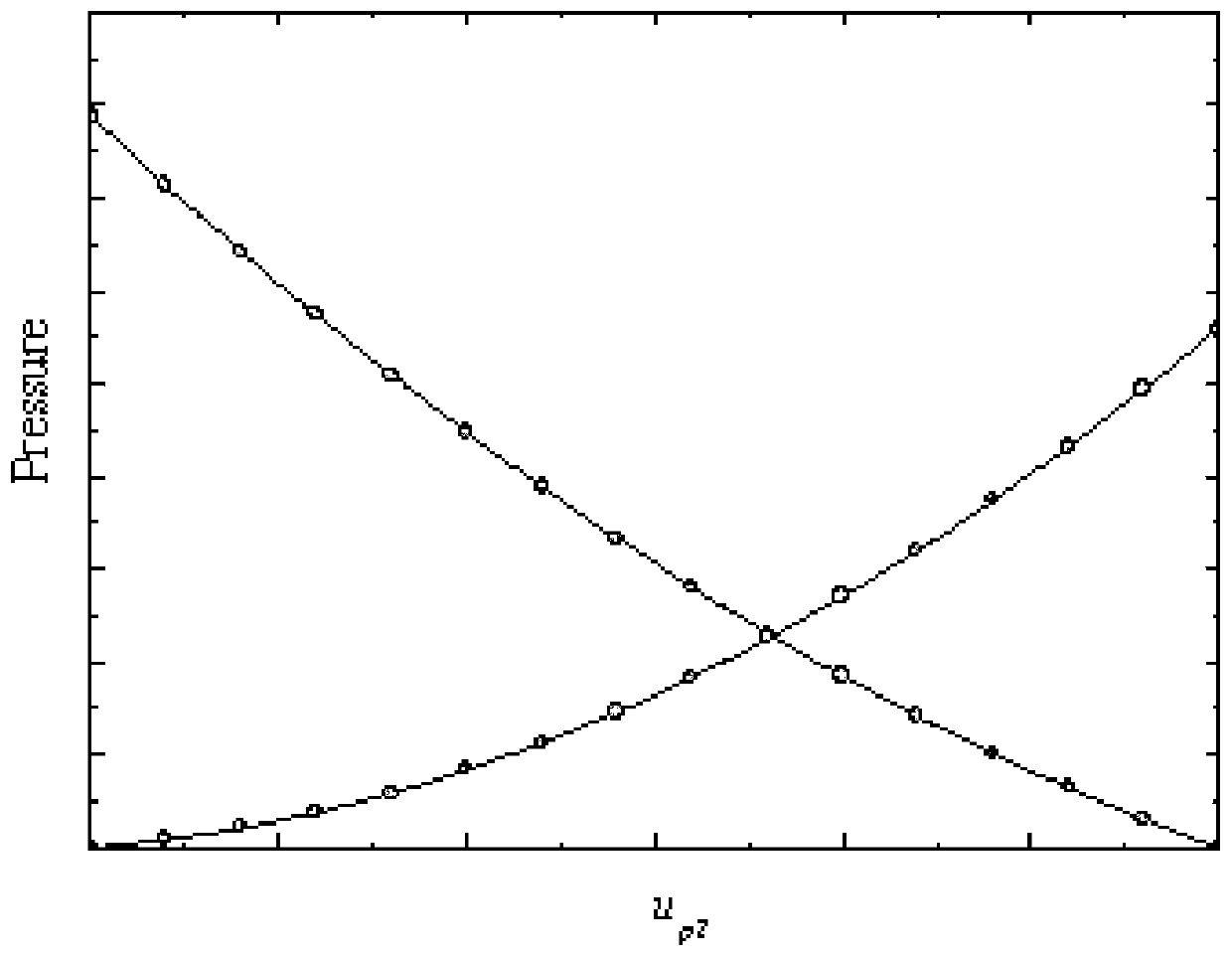

[0056] see figure 2 and image 3 , the impact pressure criterion in step b is based on the one-dimensional shock wave theory, ignoring the initial pressure before the impact of the projectile target, and using the momentum conservation equation to calculate the pressure in the projectile and the target plate, the calculation formula is:

[0057] For projectiles:

[0058] P 1 = ρ 1 u s1 mu p1

[0059] For target board:

[0060] P 2 = ρ 2 u s2 mu p2

[0061] The state equations corresponding to the projectile and the target plate are:

[0062] u s1 =C 1 +S 1 mu p1

[0063] u s2 =C 2 +S 2 mu p2

[0064] Combined with the continuous condition of the interface, we can get:

[0065] P 1 = ρ 1 (C 1 +S 1 mu p1 )μ p1 = ρ 1 C 1 mu p1 +S 1 mu p1 2

[0066] P 2 = ρ 2 (C 2 +S 2 mu p2 )μ p2 = ρ 2 C 2 mu p2 +S 1 mu p2 2 .

[0067] According to the known parameters of the material state equation, the impedance matching method is used to calcul...

Embodiment 3

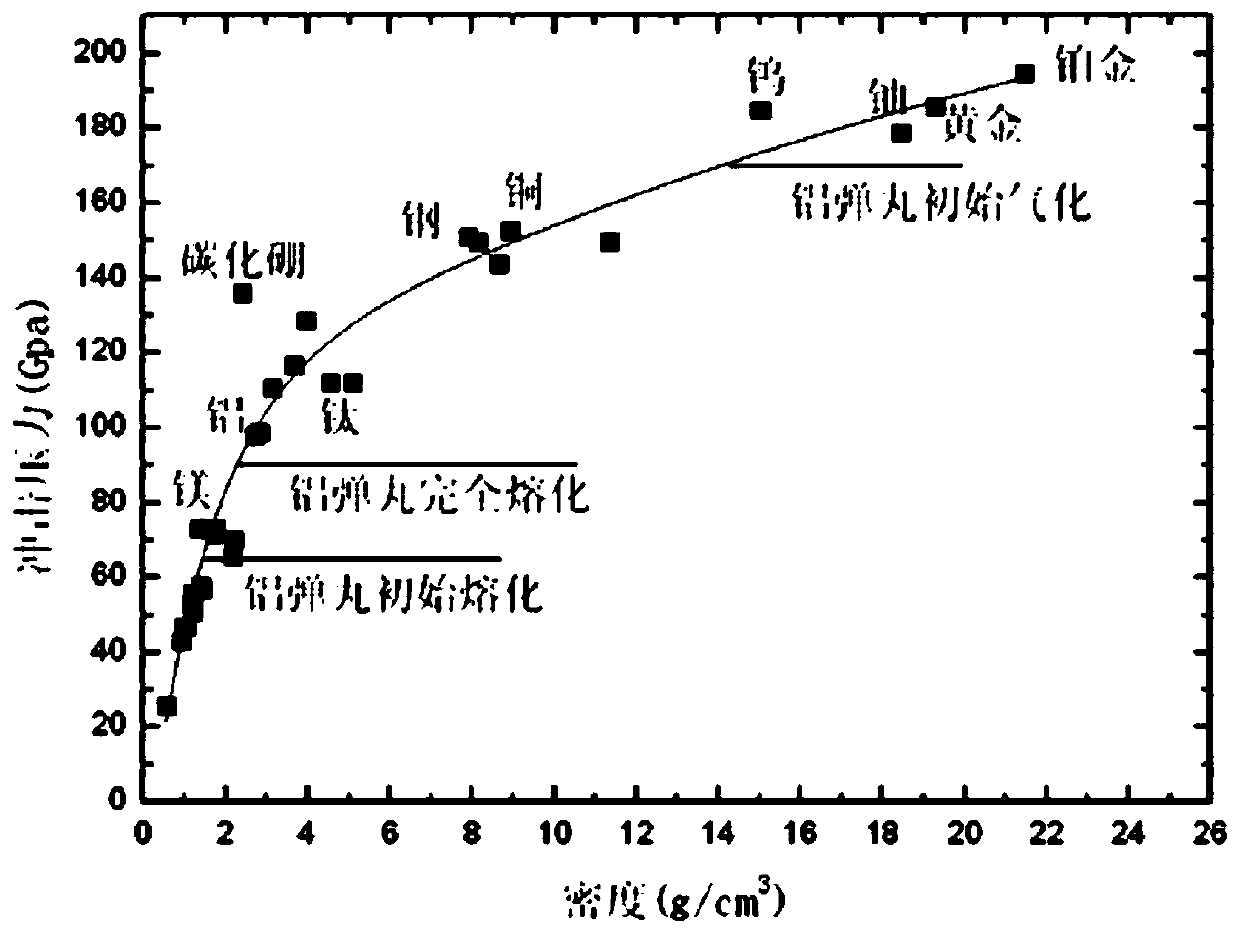

[0070] see Figure 4 , from the theory of shock wave heating, it can be known that the melting or gasification of a material is determined by the residual specific internal energy retained in the material after shock wave compression and isentropic unloading. It will lead to irreversible entropy increase of the projectile target material. The entropy increase process can be considered as adiabatic, while the unloading process under the action of sparse wave is isentropic. After the material undergoes two processes, the entropy increases, that is, the internal energy of the material increases. The increase in internal energy during the impact loading process minus the energy released during the unloading process is the remaining internal energy in the material. When the remaining specific internal energy of the material is greater than the melting specific internal energy, the material melts. When the remaining specific internal energy is greater than the gasification When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com