A kind of barium permanent magnet ferrite and preparation method thereof

A technology of permanent magnet ferrite and molded body, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of increasing production costs, losing the high cost performance of M-type permanent ferrites, and preventing excessive growth. , Conducive to uniform growth and improve coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

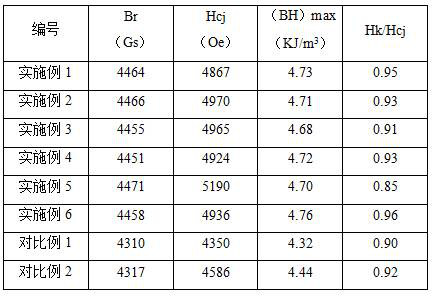

Examples

Embodiment 1

[0037] The preparation method of the present embodiment barium permanent magnet ferrite comprises the following steps:

[0038] (1) Ingredients, ball milling: weigh 1680g Fe 2 o 3 , 24.4g BaCO 3 , 72g CaCO 3 , 48.2g Co 3 o 4 , 165gLa 2 o 3 , add 2400ml of deionized water, place in a roller ball mill, and ball mill for 3 hours to obtain a mixed slurry;

[0039] (2) Drying and pre-calcination: dry the mixed slurry obtained in step (1) at 120°C for 8 hours to obtain a powder, and then pre-fire the powder at 1100°C for 2 hours in an air atmosphere to obtain a pre-fired material;

[0040] (3) Vibration milling: put the calcined material obtained in step (2) in a vibrating mill, and vibrate for 100 seconds to obtain a coarse powder with an average particle size of 3 μm;

[0041] (4) Secondary ball milling: Weigh 400g of the coarse powder obtained in step (3), add 3.2g of CaCO 3 , 0.8gBi 2 o 3 , 1gBaSi 2 o 5 , 2g calcium gluconate, 0.8 boric acid and 1200mL deionized wat...

Embodiment 2

[0044] Add 0.9%CaCO in this embodiment 3 -0.2% Bi 2 o 3 -0.25%BaSi 2 o 5 Composite sintering aid (based on the weight of coarse powder), other operating steps are the same as in Example 1.

Embodiment 3

[0046] Add 0.8%CaCO in this embodiment 3 -0.15% Bi 2 o 3 -0.25%BaSi 2 o 5 Composite sintering aid (based on the weight of coarse powder), other operating steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com