Novel pearlescent paint and preparation method thereof

A new type of pearlescent technology, applied in the direction of coating, etc., can solve the problems that cannot meet the needs of actual production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

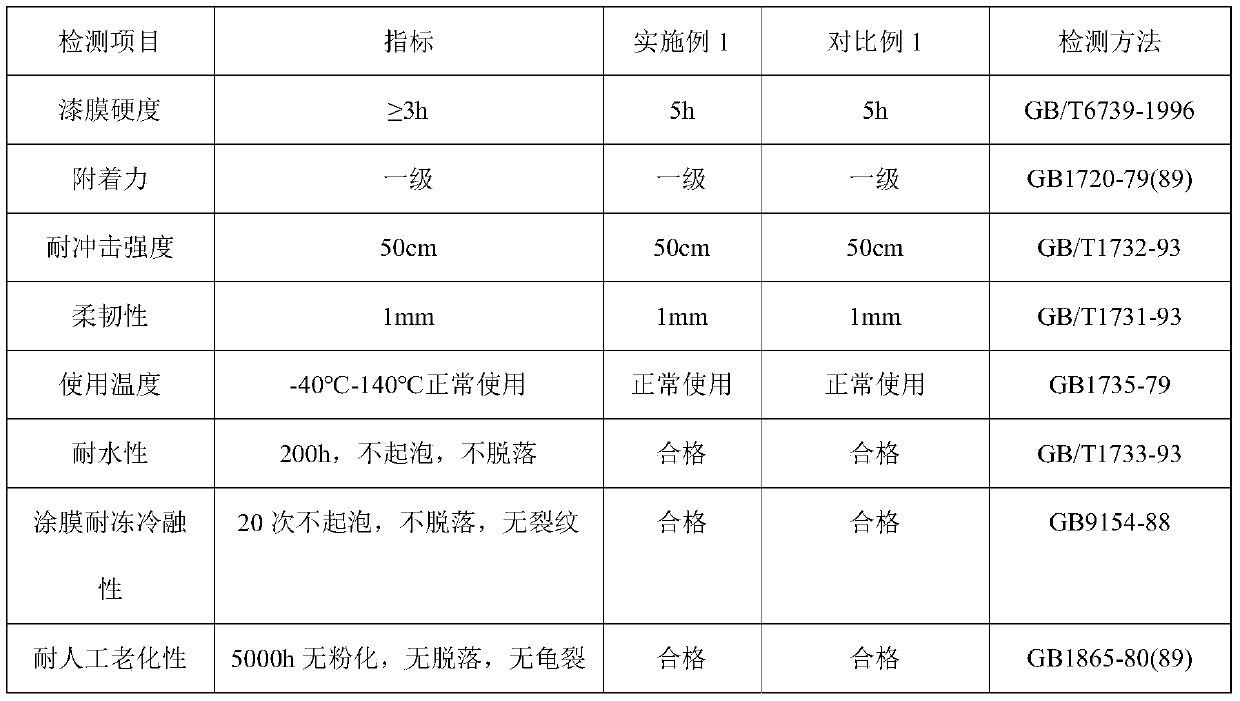

Examples

preparation example Construction

[0029] The preparation method of described pearl paste, comprises the following steps:

[0030] (1) Crushing the biomass material, adding water and stirring, adding alkali and then adding hydrogen peroxide solution, standing for 36-48h, filtering, and leaving the supernatant;

[0031] (2) Take 200 parts of supernatant liquid and 150 parts of pearlescent powder, and mix them evenly to obtain pearlescent paste.

[0032] Further, the biomass material is straw, rice straw and the like.

[0033] Further, the crushing particle size is 4-15mm.

[0034] Further, the stirring is low-speed stirring, and the speed is controlled at 200-500r / min.

[0035] Further, the concentration of the alkali solution is 100g / L, 2L-3L.

[0036] Further, the added amount of hydrogen peroxide is 0.3-0.6wt%, and the bleaching effect is better within this range.

[0037] A kind of preparation method of novel pearlescent paint, comprises the following steps:

[0038] Add thixotropic thickener, dispersan...

Embodiment 1

[0040] (1) Preparation of biological fluid

[0041] Take 1000g of straw, weeds and other crop straws, and crush them for 1 hour, with an average fineness of 4mm; put the crushed debris into the mixer and stir, add water to cover the crushed straws by 2cm, and the speed is 200rad / min; Potassium solution 2L, add hydrogen peroxide 50ml, let stand for 36h, extract the supernatant.

[0042] (2) Preparation of pearlescent paste

[0043] Take 200 parts of supernatant liquid and 150 parts of pearlescent powder, stir in the mixed solution for 1.5 hours, make pearlescent slurry, and put it in a container for later use.

[0044] (3) Preparation of new pearlescent paint

[0045] Add 267.5 parts of aqueous solution, 35 parts of thixotropic thickener CA-7035 parts, 3 parts of sodium polyacrylate, 2 parts of fatty acid, 2 parts of silicone defoamer, 350 parts, alcohol fat 12 17.5 parts, 350 parts of acrylic emulsion, 3 parts of sodium hypochlorite, stirred for 3 hours.

[0046] In order ...

Embodiment 2

[0051] (1) Preparation of pulp liquid

[0052] Take 1000g of straw, weeds and other crop straws, and crush them for 2 hours, with an average fineness of 9.5mm; put the crushed debris into the mixer and stir, add water to cover the crushed straws by 2cm, and the speed is 300rad / min; add hydrogen in turn Potassium oxide solution 2.5L, add hydrogen peroxide 60ml, let it stand for 42h, extract the supernatant.

[0053] (2) Preparation of pearlescent paste

[0054] Take 200 parts of supernatant liquid and 150 parts of pearlescent powder, stir in the mixed solution for 1.5 hours, make pearlescent slurry, and put it in a container for later use.

[0055] (3) Preparation of new pearlescent paint

[0056] Add 250 parts of aqueous solution, 3 parts of thixotropic thickener CA-703, 2 parts of sodium polyacrylate, 1 part of fatty acid, 1 part of silicone defoamer, 340 parts of pearlescent paste, and 12 parts of alcohol fat in the configuration container stirrer. 15 parts, 340 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com