Green antibacterial and bactericidal negative oxygen ion releasing coating and preparation method thereof

A technology of negative oxygen ions and negative oxygen ion powder, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., to achieve the effect of improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

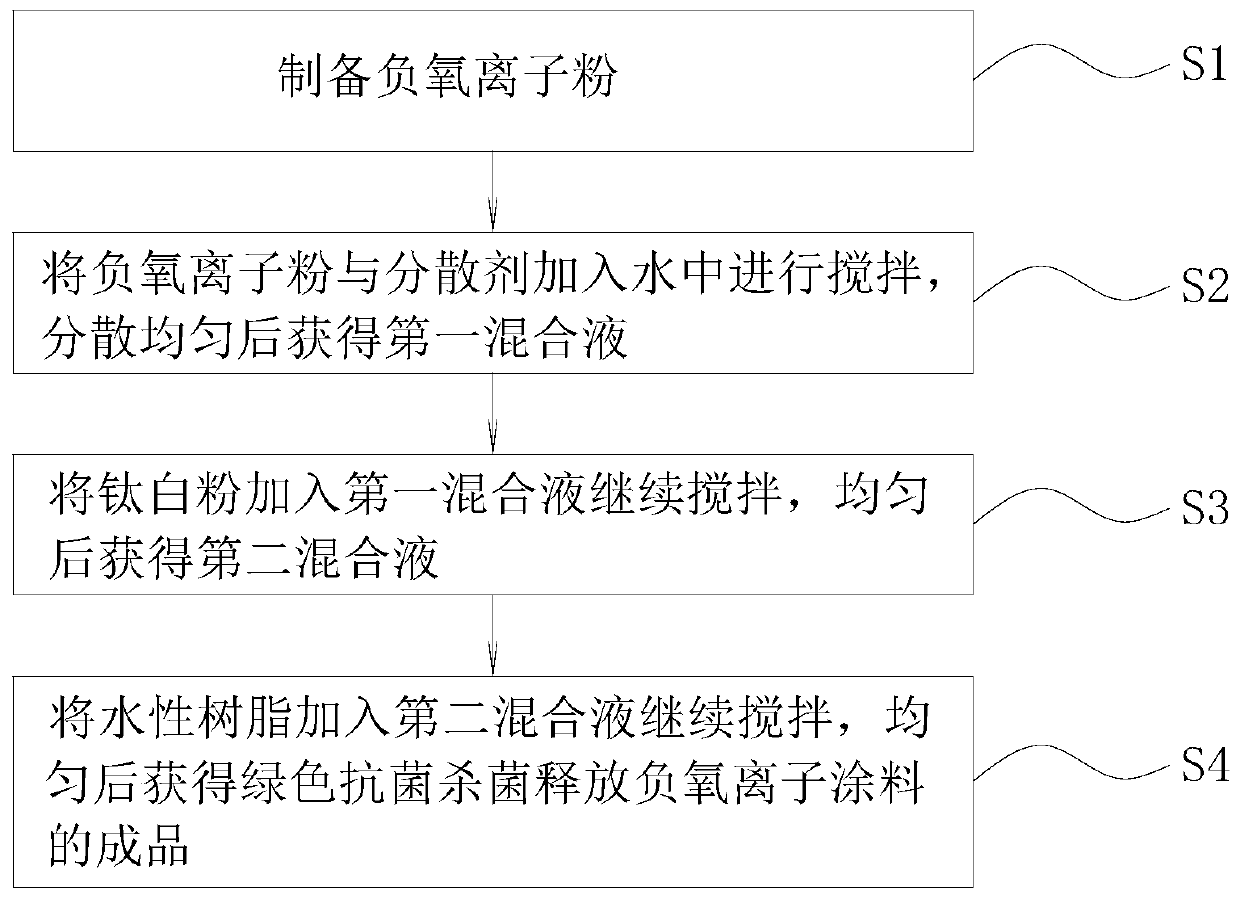

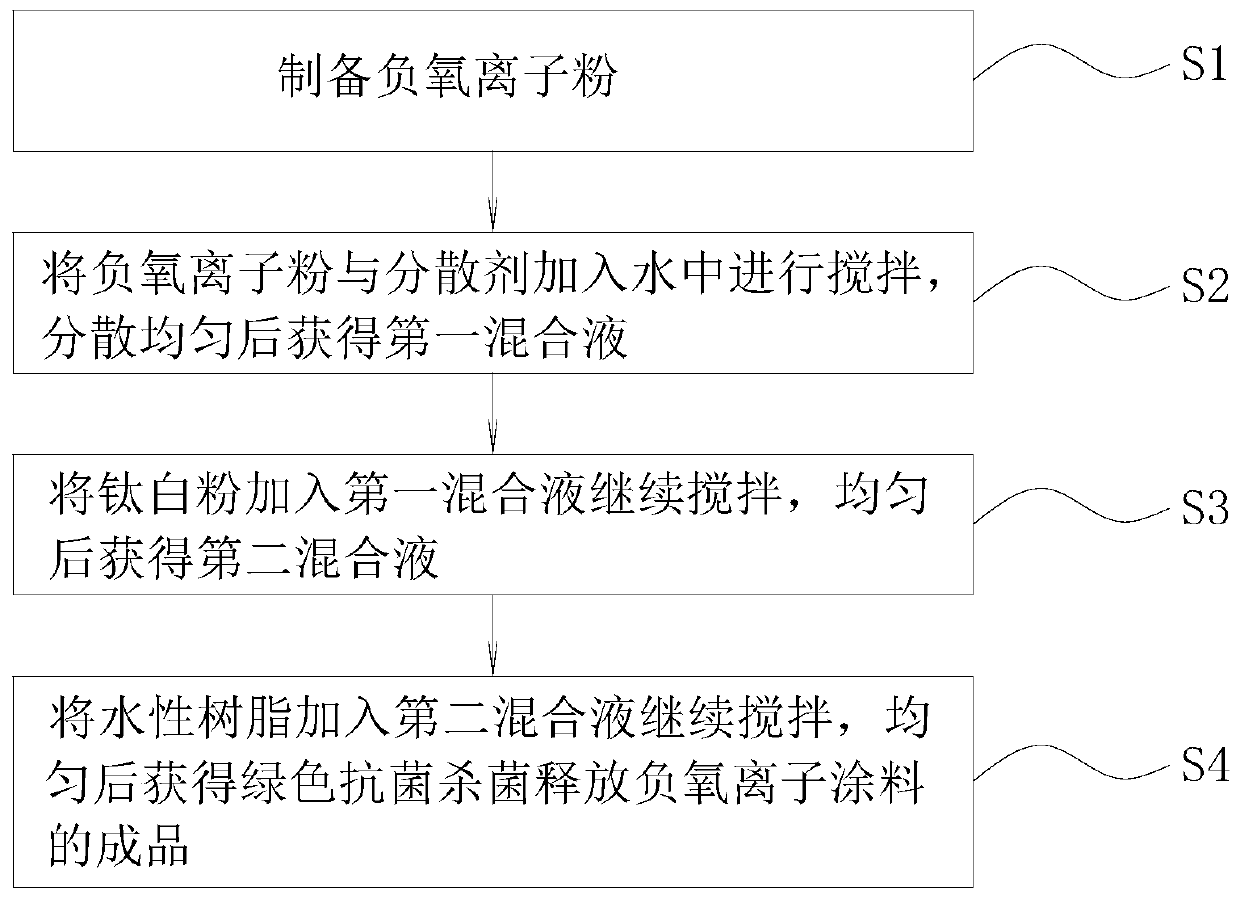

[0030] Based on the same inventive concept, the present application also provides a preparation method of green antibacterial, sterilizing and releasing negative oxygen ion coating, see attached figure 1 , including the following steps:

[0031] S1: Prepare negative oxygen ion powder;

[0032] S2: Add negative oxygen ion powder and dispersant to water for stirring, and obtain the first mixed liquid after dispersing evenly;

[0033] S3: Add titanium dioxide to the first mixed solution and continue to stir, and obtain the second mixed solution after being uniform;

[0034] S4: Add the water-based resin to the second mixed solution and continue to stir until it is uniform to obtain a finished product of green antibacterial, sterilizing and negative oxygen ion-releasing coating.

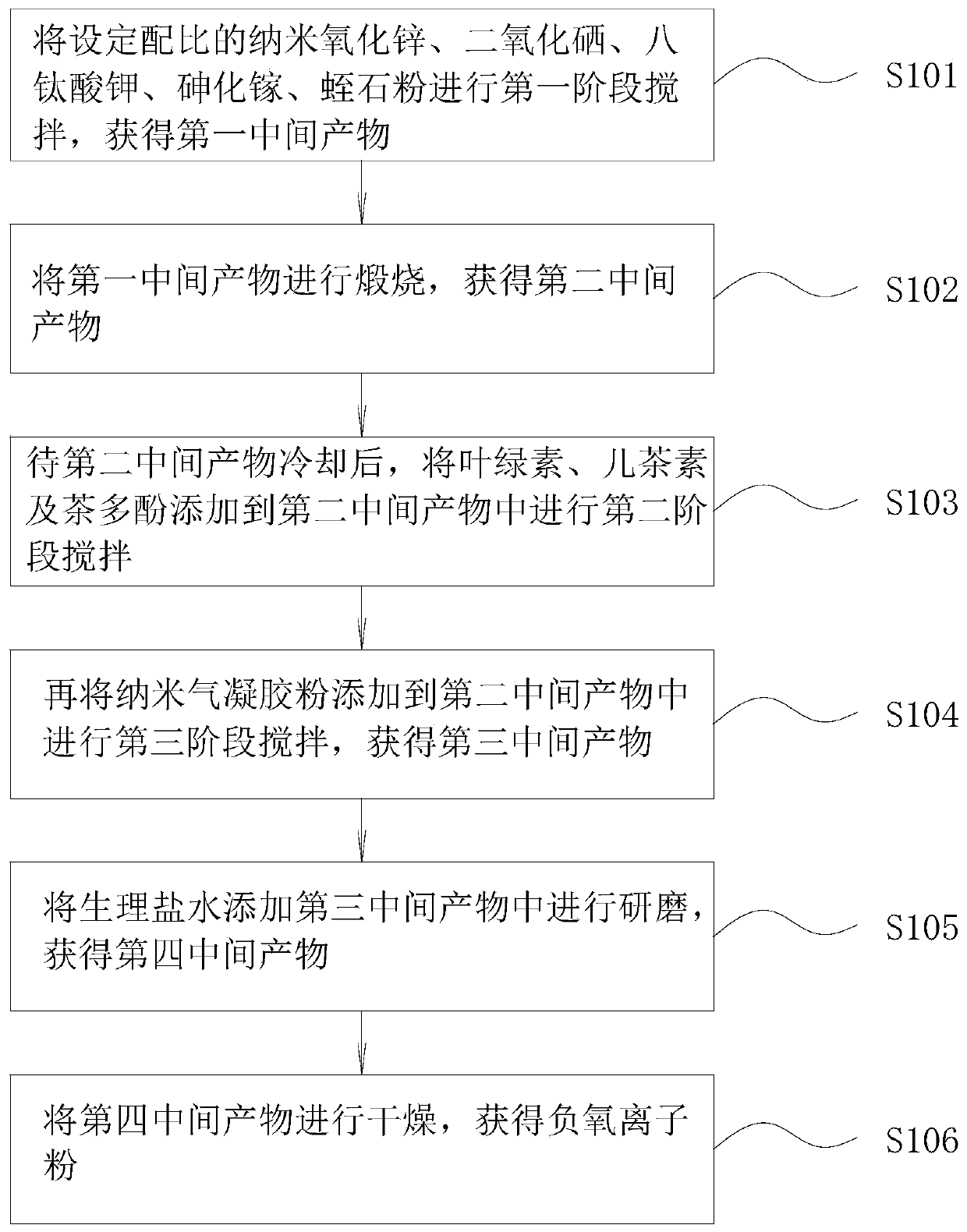

[0035] See attached figure 2 , the preparation process of negative oxygen ion powder in step S1 comprises:

[0036] S101: Stirring the nano-zinc oxide, selenium dioxide, potassium octatitanate, gall...

Embodiment 1

[0045] S1: Prepare 2 parts of negative oxygen ion powder;

[0046] S2: Add 2 parts of negative oxygen ion powder and 6 parts of dispersant into 16 parts of water for stirring, and obtain the first mixed liquid after dispersing evenly;

[0047] S3: Add 35 parts of titanium dioxide to the first mixed solution and continue to stir, and obtain the second mixed solution after being uniform;

[0048] S4: Add 40 parts of water-based resin into the second mixed solution and continue to stir, and obtain a green antibacterial, sterilizing and negative oxygen ion-releasing finished product after uniformity.

Embodiment 2

[0050] S1: prepare 3 parts of negative oxygen ion powder;

[0051] S2: Add 3 parts of negative oxygen ion powder and 6 parts of dispersant to 17 parts of water for stirring, and obtain the first mixed liquid after dispersing evenly;

[0052] S3: Add 36 parts of titanium dioxide to the first mixed solution and continue to stir, and obtain the second mixed solution after being uniform;

[0053] S4: Add 41 parts of water-based resin to the second mixed solution and continue to stir, and obtain a green antibacterial, sterilizing and negative oxygen ion-releasing finished product after uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com