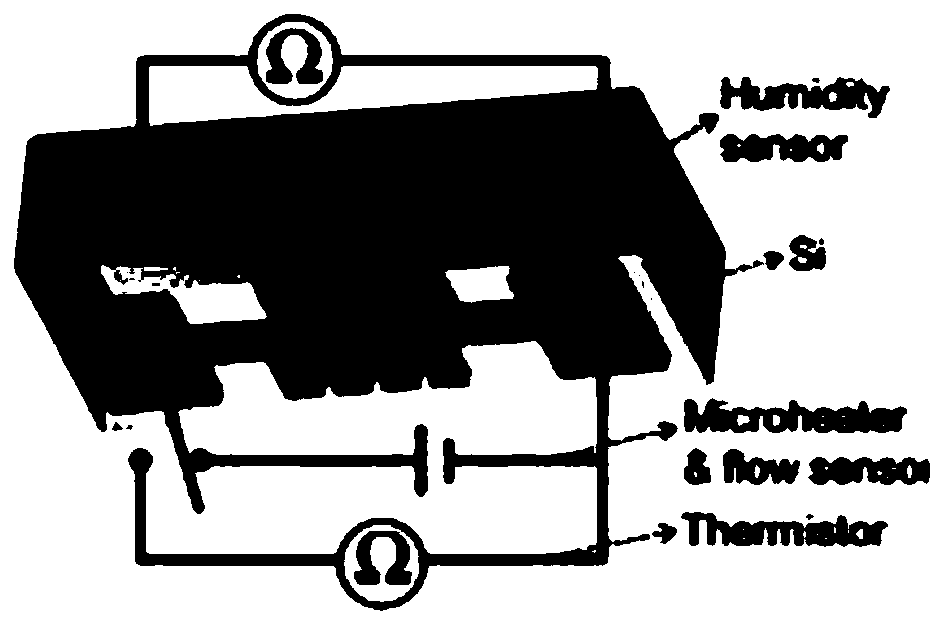

Multifunctional gas sensor capable of simultaneously detecting humidity, temperature and flow and preparation method thereof

A gas sensor, humidity sensor technology, applied in the direction of measuring devices, instruments, etc., to achieve the effect of high sensitivity, fast response, high sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of multifunctional gas sensor:

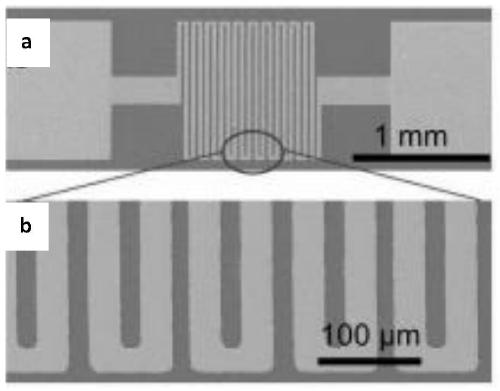

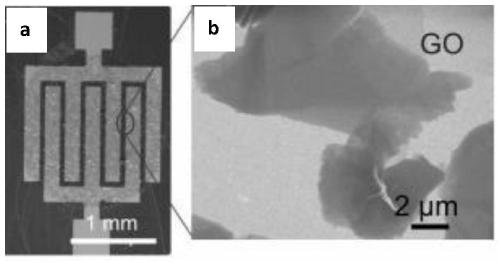

[0068] (1) Preparation of graphene oxide-based humidity sensor

[0069] By electron beam evaporation of Cr / Au, on Si / SiO 2 The interdigitated electrodes are processed on the wafer; the 0.1mg / mL graphene oxide aqueous solution is added dropwise to the interdigitated electrode surface. After the water evaporates, the graphene oxide sheet bridges the gap on the interdigitated electrode surface, and the graphene oxide-based humidity sensor is obtained. . Where Si / SiO 2 Si and SiO in wafer 2 The thicknesses of Cr and Au in the Cr / Au layer are 300 μm and 280 nm, respectively, and the thicknesses of Cr and Au are 10 nm and 70 nm, respectively.

[0070] (2) Preparation of Micro Heater

[0071] Using microfabrication techniques on Si / SiO 2 Prepare a micro heater array at a position opposite to the humidity sensor prepared in step S1 on the substrate, specifically, use a photoresist (thickness of 4 μm) to spin-coat on Si / SiO 2 A...

Embodiment 2

[0082] Preparation of multifunctional gas sensor:

[0083] (1) Preparation of graphene oxide-based humidity sensor

[0084] Process interdigitated electrodes on Si substrates by electron beam evaporation of Cr / Au; 0.15mg / mL graphene oxide aqueous solution is added dropwise to the surface of interdigitated electrodes, after water evaporates, graphene oxide sheets bridge the interdigitated electrode surface The gap of the graphene oxide-based humidity sensor is obtained. The thicknesses of Cr and Au in the Cr / Au layer are 10 nm and 70 nm, respectively.

[0085] (2) Preparation of Micro Heater

[0086] Use micromachining technology to prepare a micro-heater array at a position opposite to the humidity sensor prepared in step S1 on the Si substrate, specifically use a photoresist (thickness of 4 μm) to spin-coat on the Si substrate to perform a photolithography process, Subsequent sputtering of the Cr / Pt layer and a lift-off process yielded serpentine platinum microwires on the...

Embodiment 3

[0088] Preparation of multifunctional gas sensor:

[0089] (1) Preparation of graphene oxide-based humidity sensor

[0090] Process interdigitated electrodes on LCP flexible films by electron beam evaporation of Cr / Au; 0.1mg / mL graphene oxide aqueous solution is added dropwise to the surface of interdigitated electrodes, after water evaporates, graphene oxide sheets bridge the interdigitated electrodes surface gaps, resulting in a graphene oxide-based humidity sensor. The thicknesses of Cr and Au in the Cr / Au layer are 10 nm and 70 nm, respectively.

[0091] (2) Preparation of Micro Heater

[0092] Use microfabrication technology to prepare a micro-heater array on the LCP flexible film at a position opposite to the humidity sensor prepared in step S1, specifically, use a photoresist (thickness of 4 μm) to spin-coat on the LCP flexible film for photolithography process, followed by sputtering of the Cr / Pt layer and a lift-off process to obtain serpentine platinum microwires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com