Intrinsic safety type vortex street flow sensor for oiling machine gas phase recovery measurement

A vortex flow, intrinsically safe technology, applied in the field of flow sensors, can solve problems such as abnormal use, slow gas flow reflection speed, and Roots flowmeter blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

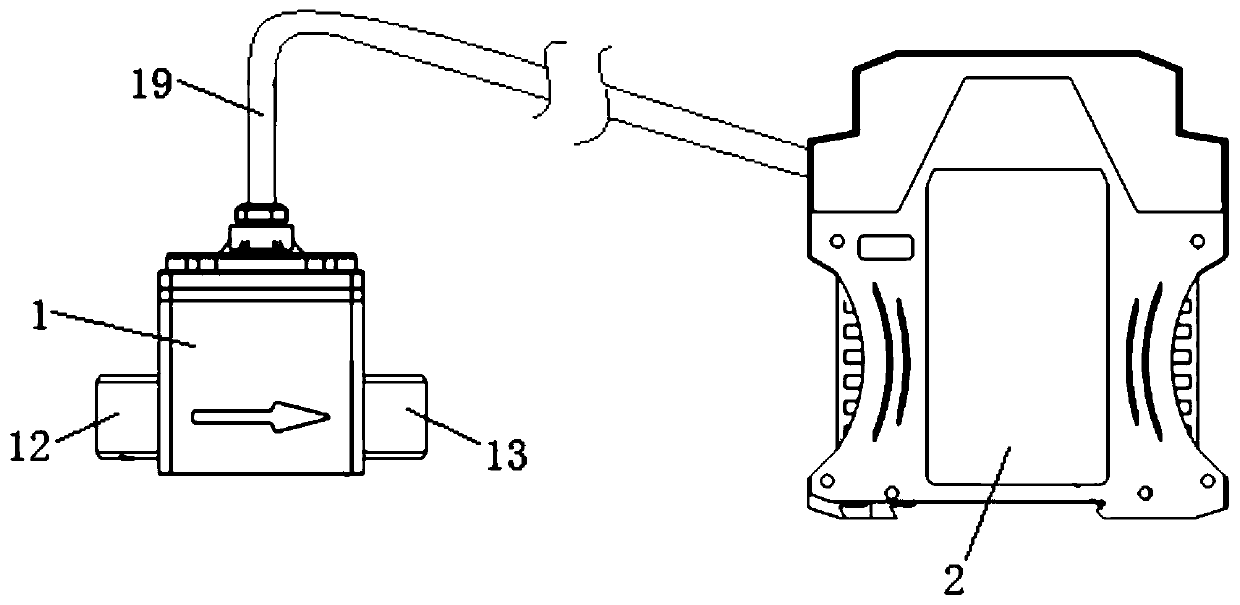

[0158] An intrinsically safe vortex flow sensor for gas phase recovery measurement of a fuel dispenser, the specific implementation of which is as follows:

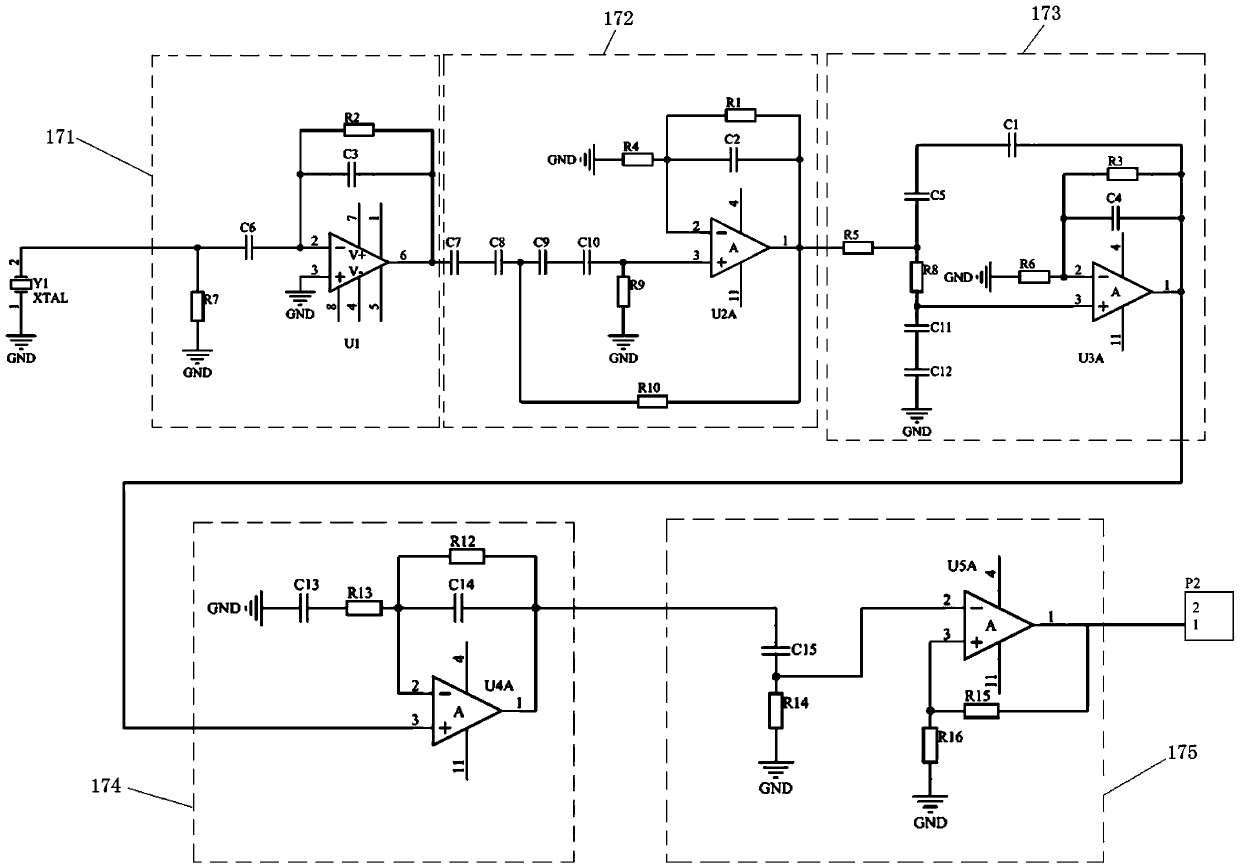

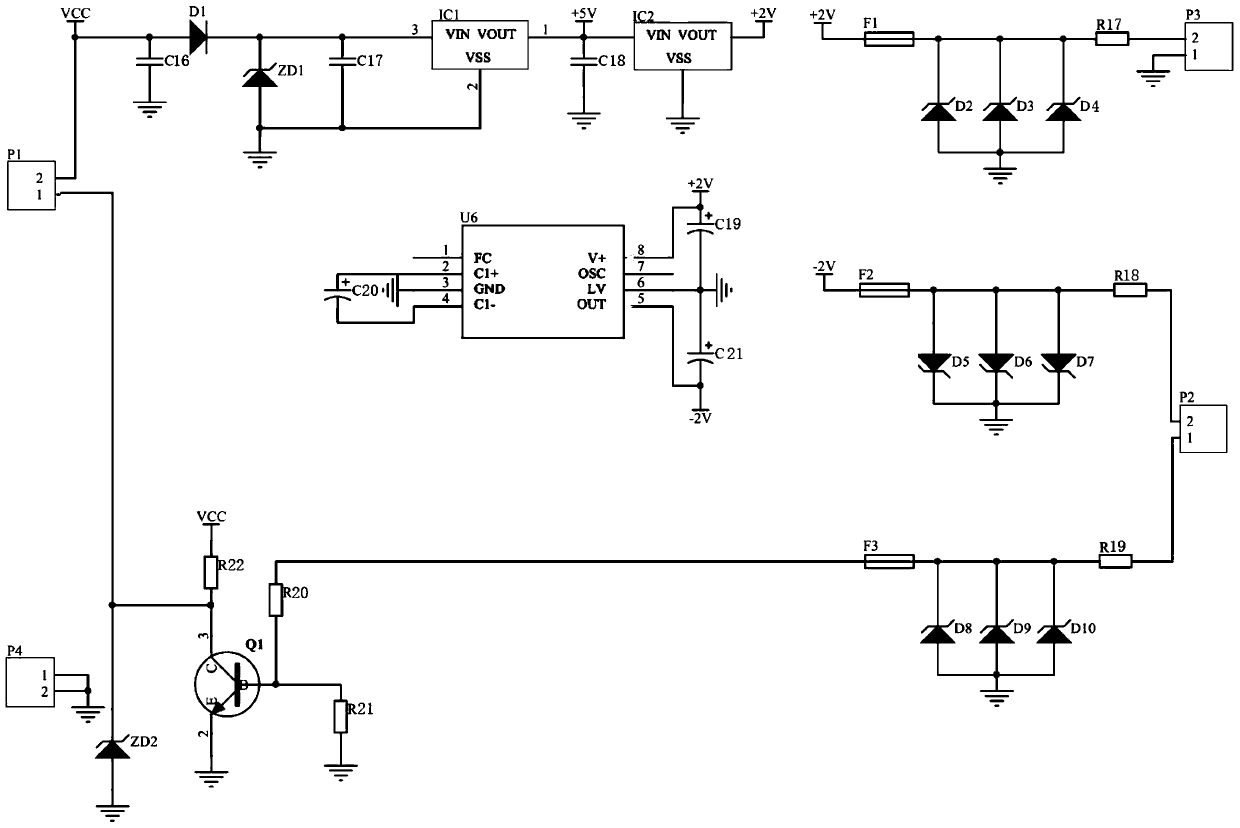

[0159] The gas phase enters through the inlet port 12, and the pressure of the airflow increases after passing through the necking structure. After passing through the spoiler column 16, a Karman vortex will be formed in the flow chamber 14 at the lower part of the piezoelectric crystal 15, and through the installed high-sensitivity piezoelectric crystal 15 Detect the weak pulse charge signal of Karman vortex formation. After the pulse charge signal detected by the piezoelectric crystal 15 passes through the five-stage amplification of the filter amplifier circuit, the finally output pulse signal enters the safety barrier 2 through the cable 19, and is shaped by the digital signal conversion circuit in the safety barrier 2, and finally output to the Other instruments or flow totalizers are used to achieve the purpose of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com