Automatic winding production line for one-piece inductors

A production line and automatic technology, applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., can solve the problems of large-scale production of inductors that do not meet the requirements of integrated molding, high labor costs, and solder joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

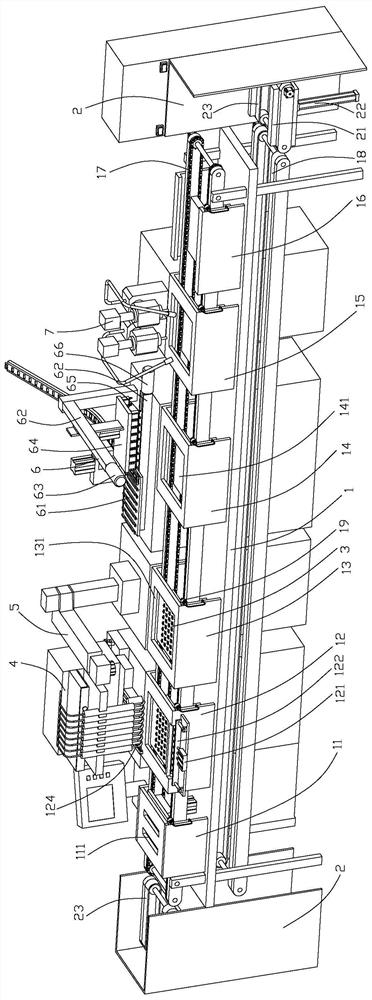

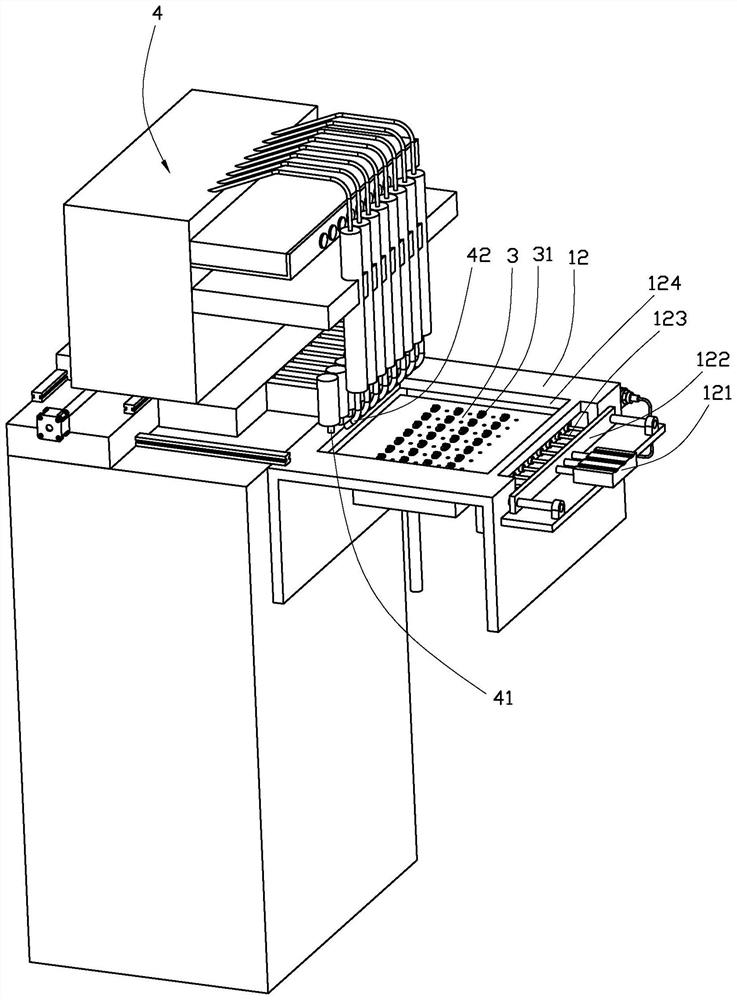

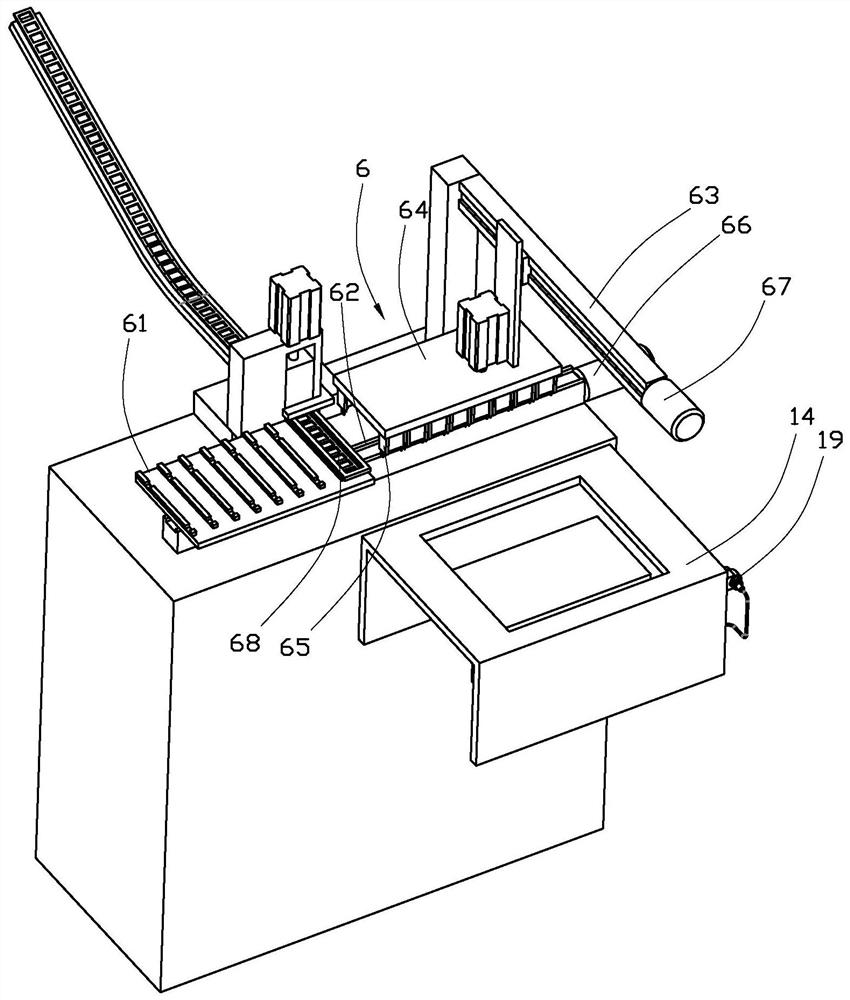

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] refer to figure 1 , Figure 4 , which is an automatic winding production line for integrally formed inductors disclosed in the present invention, including an assembly line workbench 1, a cycle conversion workbench 2 is installed at both ends of the assembly line workbench 1, and pre-winding wires are sequentially installed on the assembly line workbench 1 Work station 11, winding station 12, detection station 13, strip assembly station 14, laser welding station 15, material separation station 16, the upper part of assembly line workbench 1 is installed along its length direction There is a transmission chain 17 for transmitting the coil fixture 3 of the load, and a transmission belt 18 for transmitting the unloaded coil fixture 3 is installed on the lower part of the assembly line workbench 1 along its length direction. Winding station 11, winding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com