3D NAND memory and manufacturing method thereof

A 3D NAND and manufacturing method technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of poor uniformity of selective epitaxial structure, insufficient substrate cleanliness, incomplete cleaning, etc., and achieve easy control of the patterning process , Reduce the risk of leakage and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

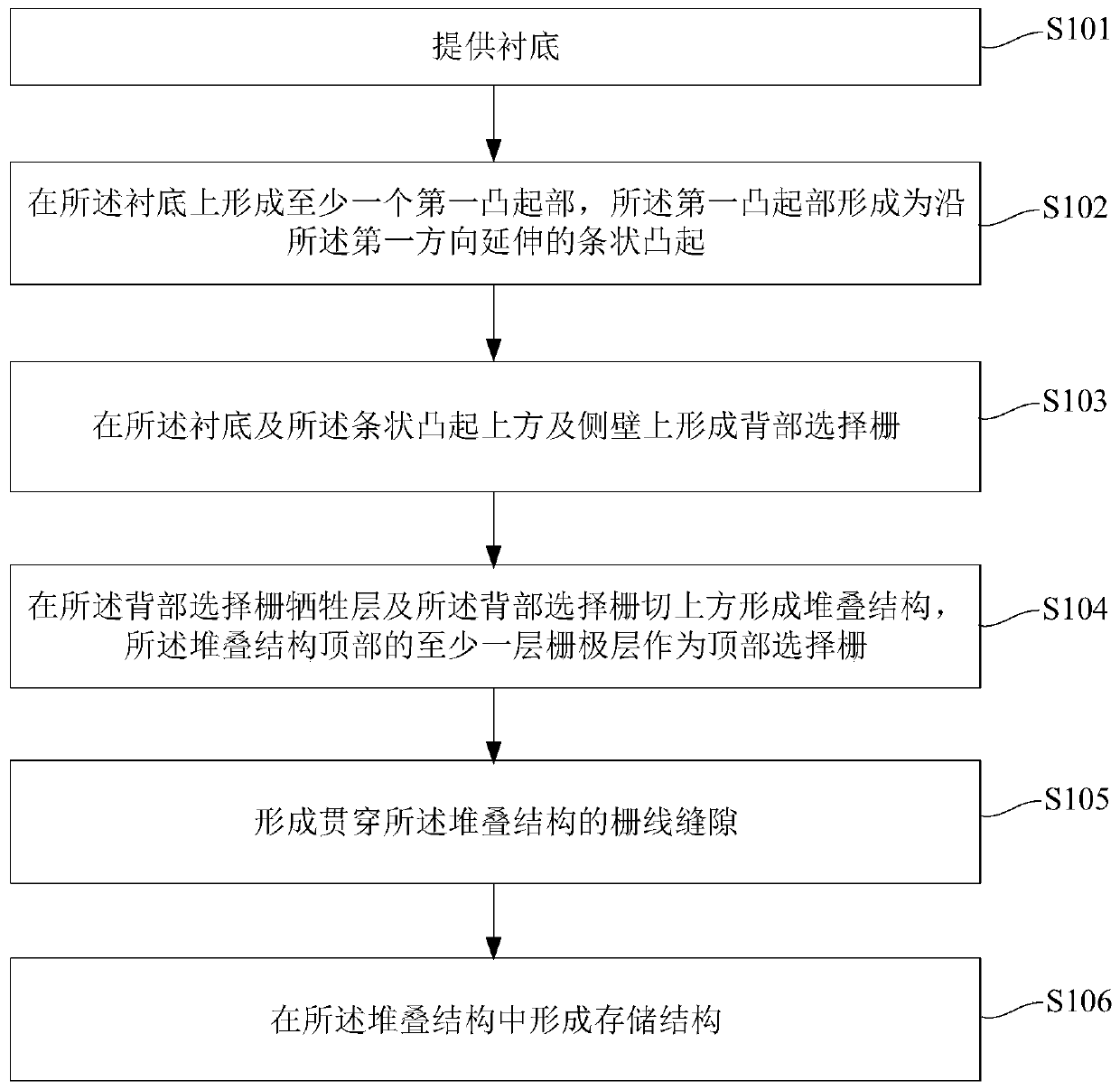

[0128] This embodiment provides a method for manufacturing a 3D NAND memory, such as figure 1 As shown, the method includes the following steps:

[0129] Step S101: providing a substrate;

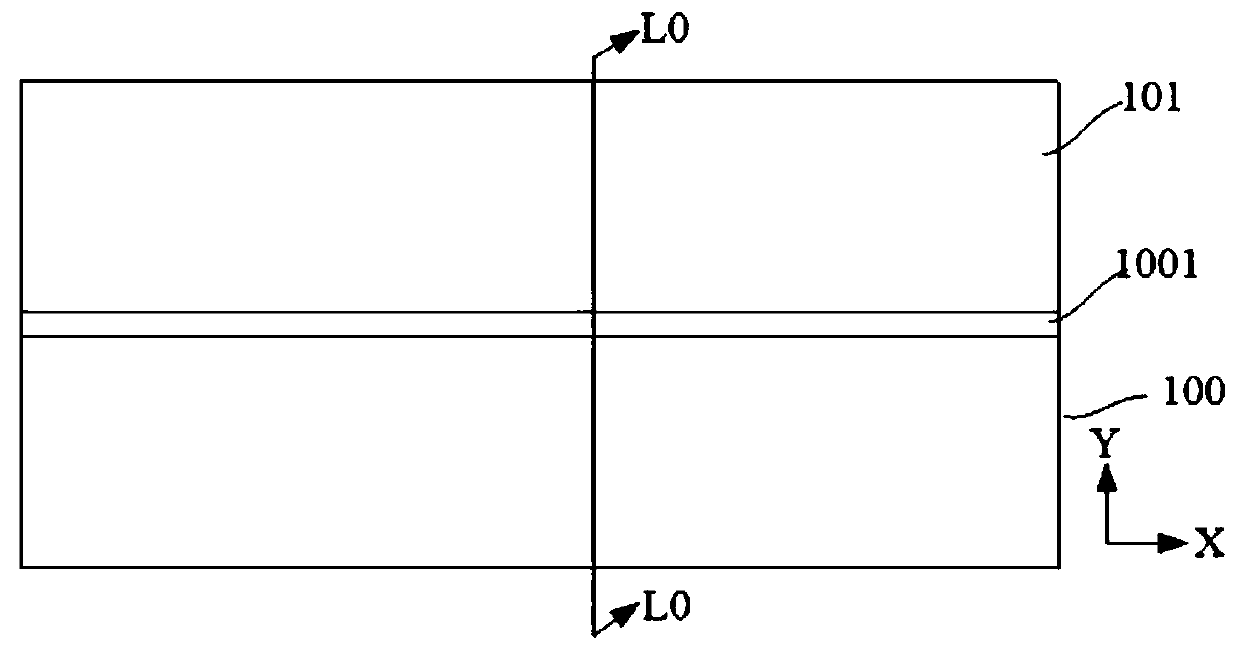

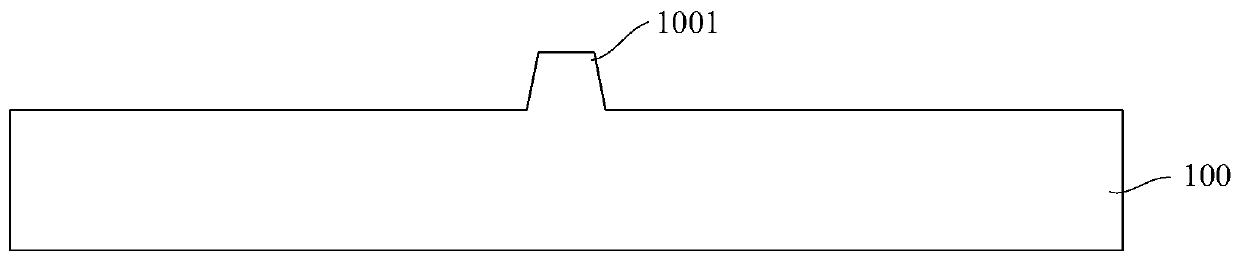

[0130] refer to figure 2 , a substrate 100 is provided, and the substrate 100 extends in the X direction (first direction) and the Y direction (second direction). The material of the substrate 100 can be single crystal silicon (Si), single crystal germanium (Ge), or silicon germanium (GeSi), silicon carbide (SiC); it can also be silicon on insulator (SOI), germanium on insulator (GOI ); or other materials, such as III-V group compounds such as gallium arsenide. In this embodiment, the material of the semiconductor substrate 100 is single crystal silicon (Si).

[0131] Step S102: forming at least one first raised portion on the substrate, the first raised portion being formed as a strip-shaped protrusion extending along the first direction;

[0132] Such as figure 2 and image 3 As ...

Embodiment 2

[0148] This embodiment also provides a method for manufacturing a 3D NAND memory. The similarities between the manufacturing method of this embodiment and the manufacturing method described in Embodiment 1 will not be repeated, and the differences are described in detail as follows:

[0149] refer to Figure 17 In this embodiment, a plurality of second protrusions 107 distributed in an array are formed on the substrate 100 at the same time as the first protrusions are formed on the patterned substrate 100 . Such as Figure 18 As shown, the second protrusions 107 are columnar protrusions distributed in an array. Preferably, the first raised portion and the second raised portion have the same height.

[0150]In a preferred embodiment of this embodiment, after the formation of the first protrusions, the substrate may be patterned again to form a plurality of second protrusions 107 . The second raised portion may be formed simultaneously or after the first raised portion may be...

Embodiment 3

[0161] This embodiment provides a kind of 3D NAND memory, refer to the attached figure 2 ~ attached Figure 15 , the 3D NAND memory includes:

[0162] A substrate 100, the substrate 100 extends in a first direction (X direction) and a second direction (Y direction) perpendicular to each other, the substrate 100 includes at least one first raised portion 102, the first raised portion 102 forms It is a strip-shaped protrusion extending along the X direction. The material of the substrate 100 can be single crystal silicon (Si), single crystal germanium (Ge), or silicon germanium (GeSi), silicon carbide (SiC); it can also be silicon on insulator (SOI), germanium on insulator (GOI) ; or other materials, such as III-V group compounds such as gallium arsenide. In this embodiment, the material of the semiconductor substrate 100 is single crystal silicon (Si).

[0163] A back selection gate formed on the substrate, the back selection gate comprising a back selection gate oxide and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com