Stainless steel/carbon steel composite pipe and manufacturing process thereof

A production process, stainless steel technology, applied in the direction of manufacturing tools, pipes/pipe joints/fittings, pipes, etc., can solve the problems of temperature control, surface quality, production efficiency, etc., to improve Su Song (shrinkage cavity) and segregation, and avoid irregularities The effect of shape and inner wall smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A manufacturing process of stainless steel / carbon steel composite pipe, comprising the following steps:

[0049] (1) Surface treatment of the base pipe

[0050] Take a carbon steel pipe, finish the inner wall of the base pipe, and then process a joint surface with roughness. Iron filings during processing can be recycled.

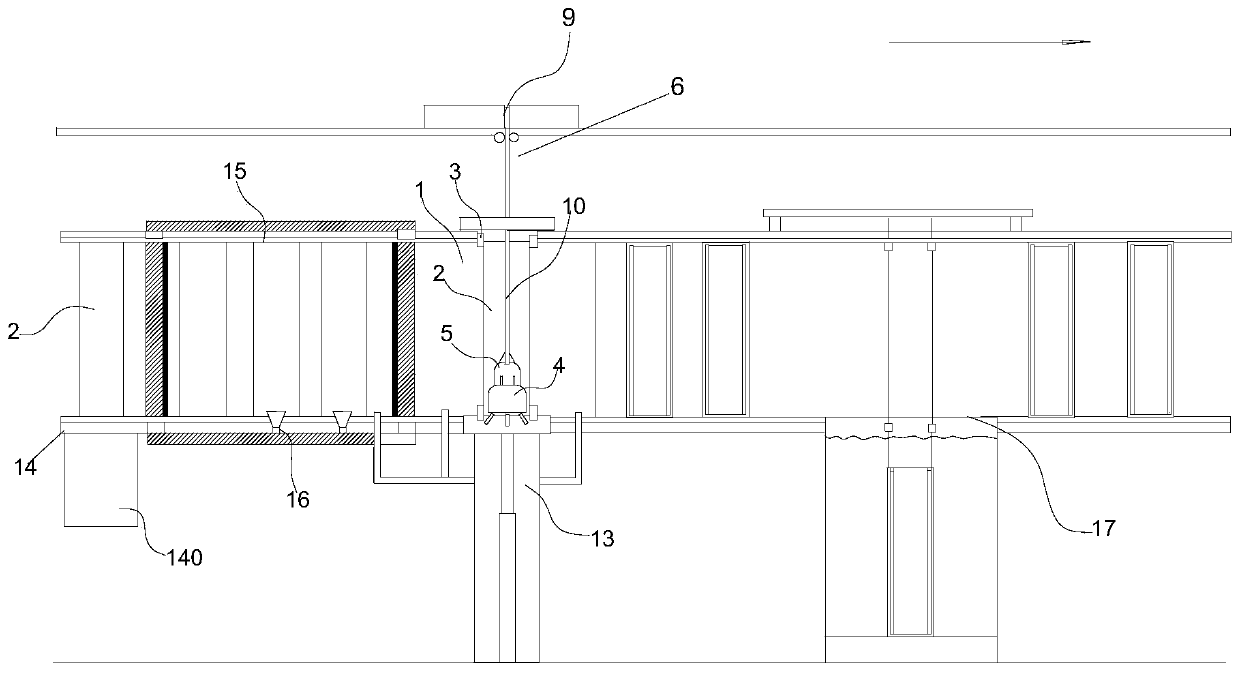

[0051] (2) Preheating of the base pipe

[0052] The base pipe is transported to a heating furnace and preheated in an inert atmosphere or a reducing atmosphere to reach the preheating temperature required for casting. Preheating includes the following specific process: first use the heating furnace to preheat the internal environment of the furnace body and then preheat the base pipe. The warm-up time is 10h.

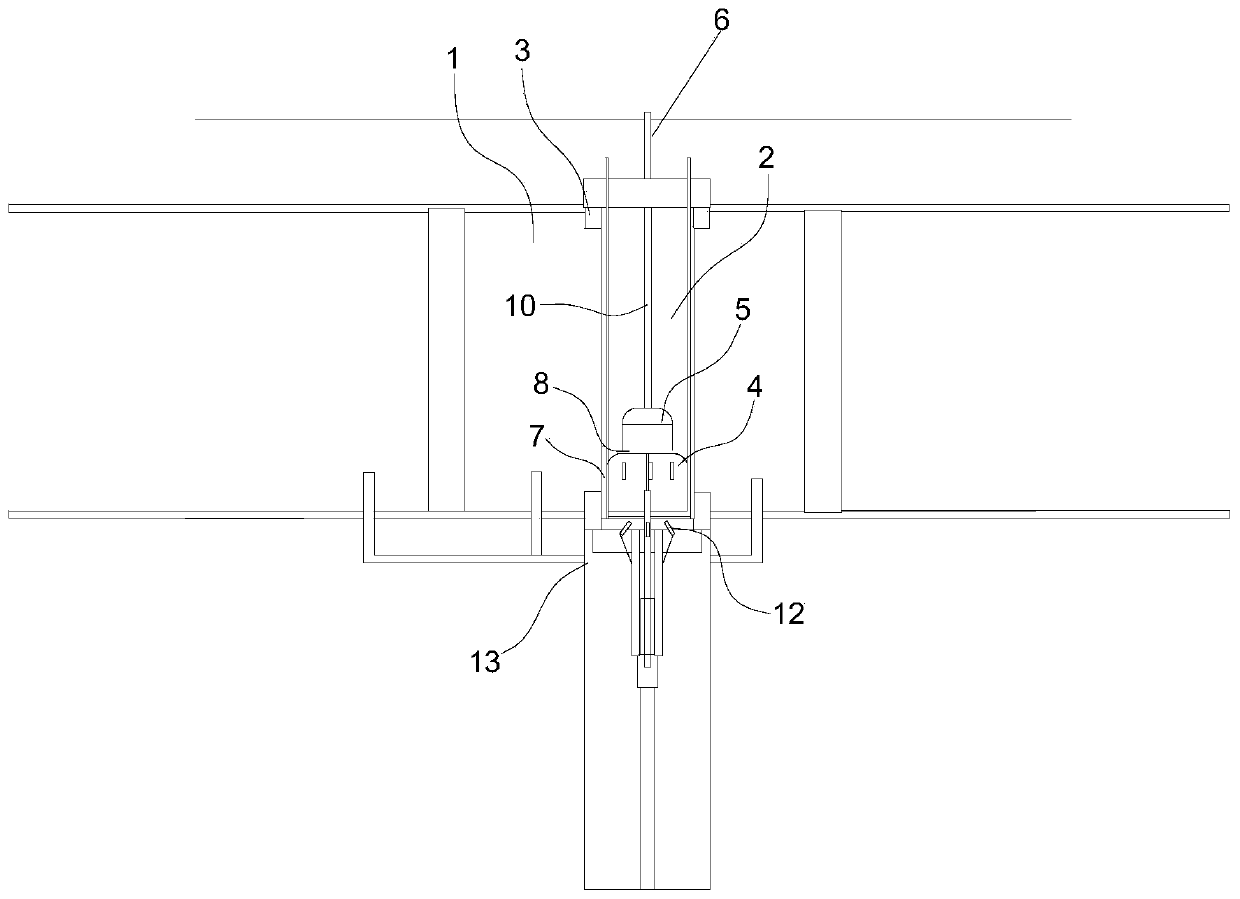

[0053] (3) Pouring

[0054] Transfer the base pipe to the pouring area, then lift the ceramic mold to the inner bottom of the base pipe and center it, a pouring cavity is formed between the ceramic mold and the base pipe, and the The ste...

Embodiment 2

[0059] A manufacturing process of stainless steel / carbon steel composite pipe, comprising the following steps:

[0060] (1) Surface treatment of the base pipe

[0061] Take a carbon steel pipe, finish the inner wall of the base pipe, and then process a joint surface with roughness. Iron filings during processing can be recycled.

[0062] (2) Preheating of the base pipe

[0063] The base pipe is transported to a heating furnace and preheated in an inert atmosphere or a reducing atmosphere to reach the preheating temperature required for casting. Preheating includes the following specific process: first use the heating furnace to preheat the environment inside the furnace body and then preheat the base pipe. The warm-up time is 0.1h.

[0064] (3) Pouring

[0065] Transfer the base pipe to the pouring area, then lift the ceramic mold to the inner bottom of the base pipe and center it, a pouring cavity is formed between the ceramic mold and the base pipe, and the The steel l...

Embodiment 3

[0070] A manufacturing process of stainless steel / carbon steel composite pipe, comprising the following steps:

[0071] (1) Surface treatment of the base pipe

[0072] Take a carbon steel pipe, finish the inner wall of the base pipe, and then process a joint surface with roughness. Iron filings during processing can be recycled.

[0073] (2) Preheating of the base pipe

[0074] The base pipe is transported to a heating furnace and preheated in an inert atmosphere or a reducing atmosphere to reach the preheating temperature required for casting. Preheating includes the following specific process: first use the heating furnace to preheat the internal environment of the furnace body and then preheat the base pipe. The warm-up time is 5h.

[0075] (3) Pouring

[0076] Transfer the base pipe to the pouring area, then lift the ceramic mold to the inner bottom of the base pipe and center it, a pouring cavity is formed between the ceramic mold and the base pipe, and the The stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap