Tire casing and tire bead separation mechanism of waste truck tire cover breaking robot

A robot and carcass technology, which is applied in recycling technology, plastic recycling, etc., can solve problems such as inability to realize clamping and processing, troublesome automatic production, and easily damaged tools, so as to reduce the difficulty of fixture design, realize automatic production, and avoid The effect of manual manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

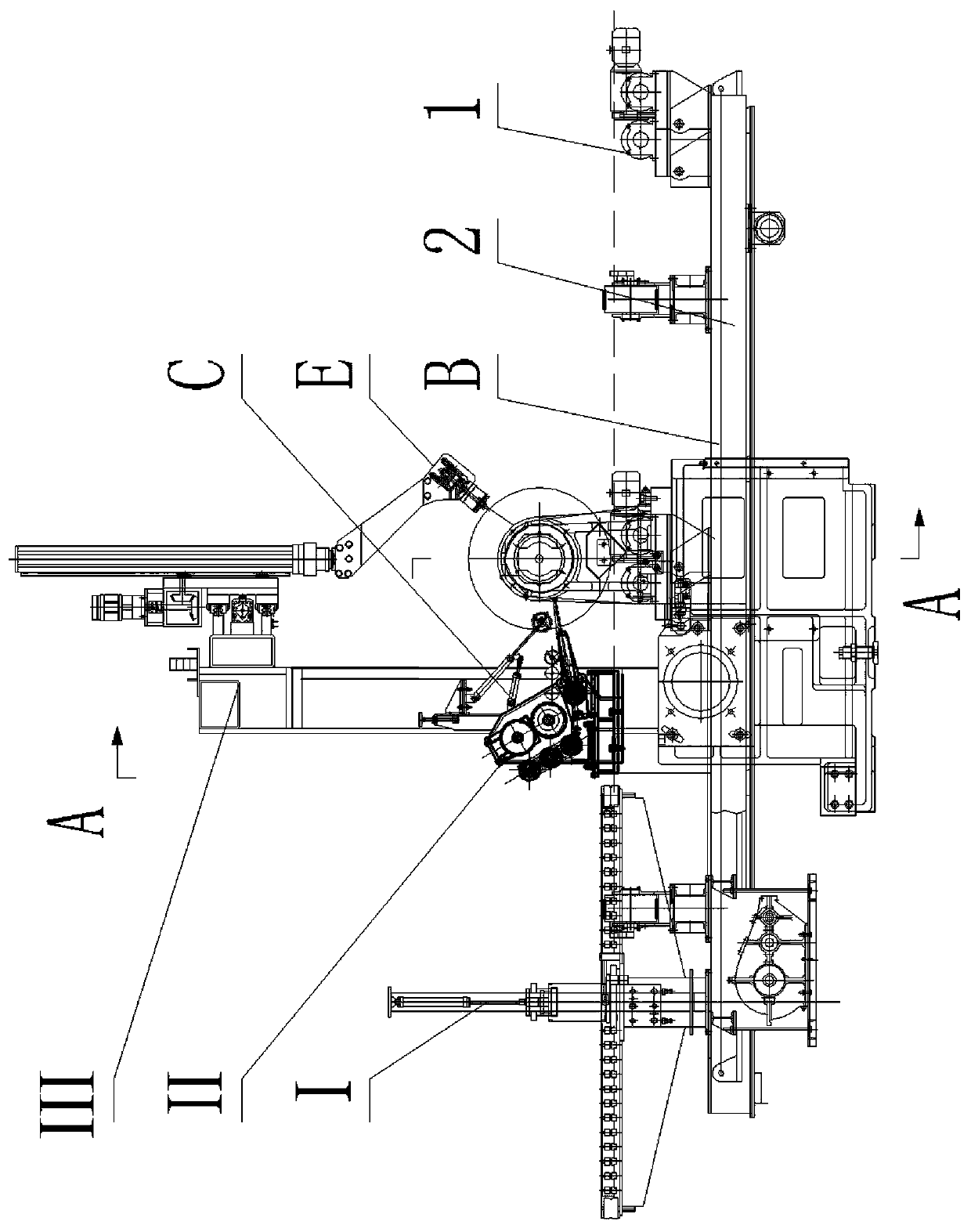

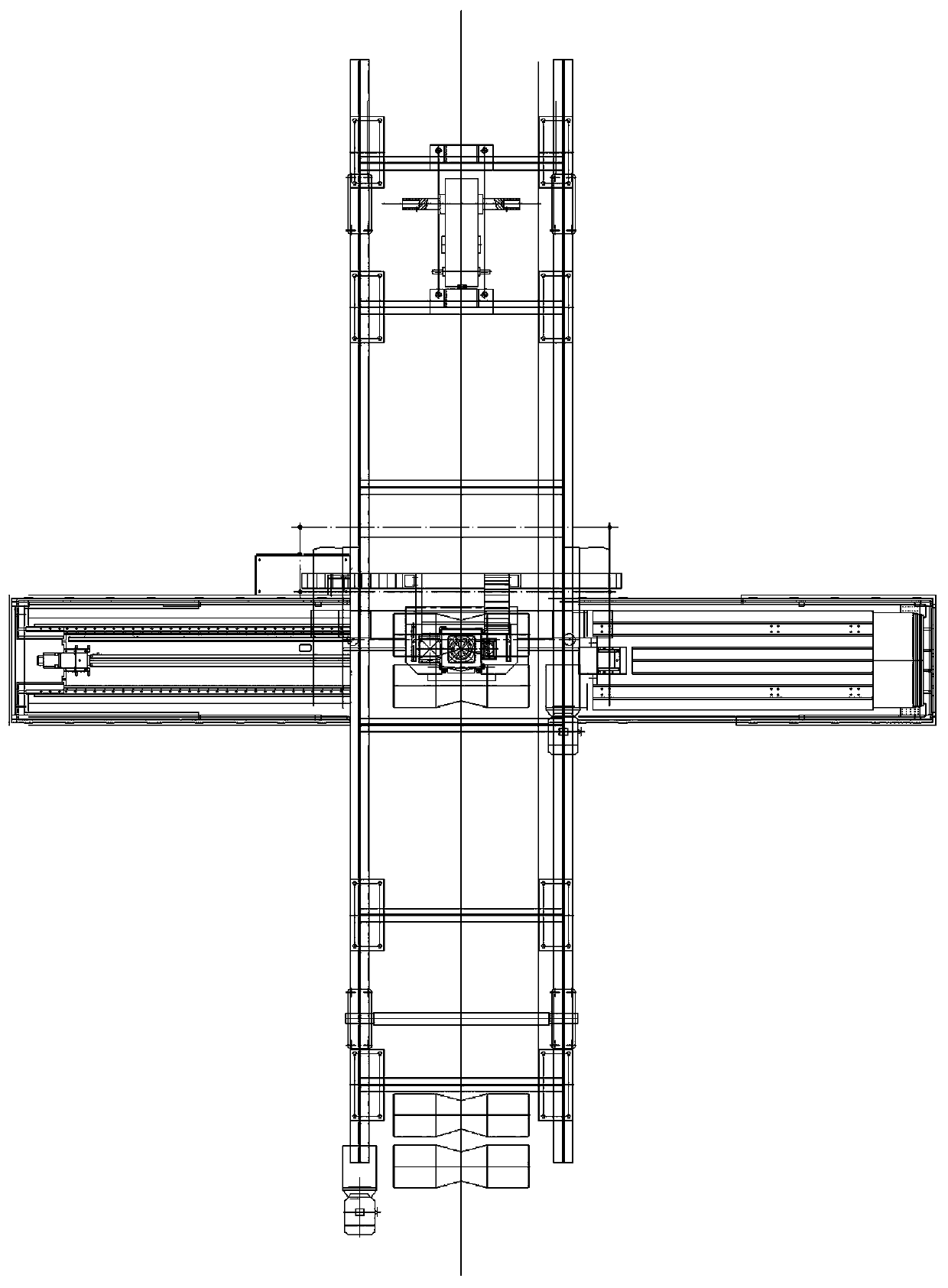

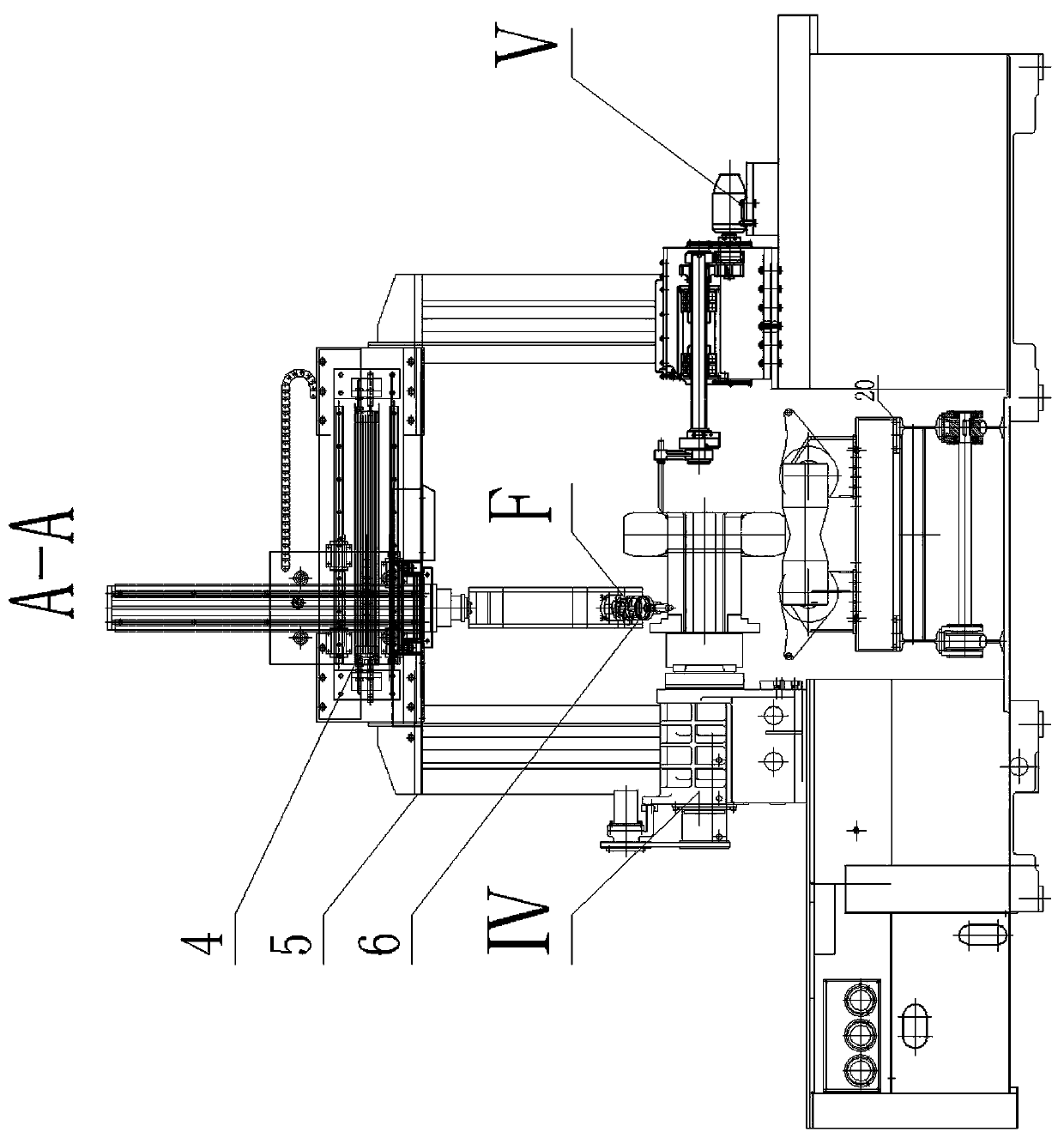

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the waste truck tire casing crushing robot separates the carcass and bead mechanism, which is characterized by: including the turnover track trolley Ⅰ, the carcass grabbing roller machine Ⅱ, the portal carcass cutting machine Ⅲ, and the three-jaw power card Disc table IV, boring and cutting feed box V.

[0028] The turnover track trolley Ⅰ includes a collection nip roller assembly 1, a track trolley 2, and a bow-shaped chain roller grinding machine 3. The turnover track trolley I reciprocates along a straight line of the track, and the track is designed with two stations , the distance between the two stations is equal to the distance between the processing center of the collection nip roller assembly 1 and the bow-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com