Adsorption resin for removing perfluorinated pollutants in water body as well as preparation and application of adsorption resin

A technology for adsorbing resin and pollutants, which is applied in the field of macroporous adsorbent resin and its preparation to achieve the effects of improving adsorption efficiency and capacity, increasing specific surface area, and improving use effect and application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

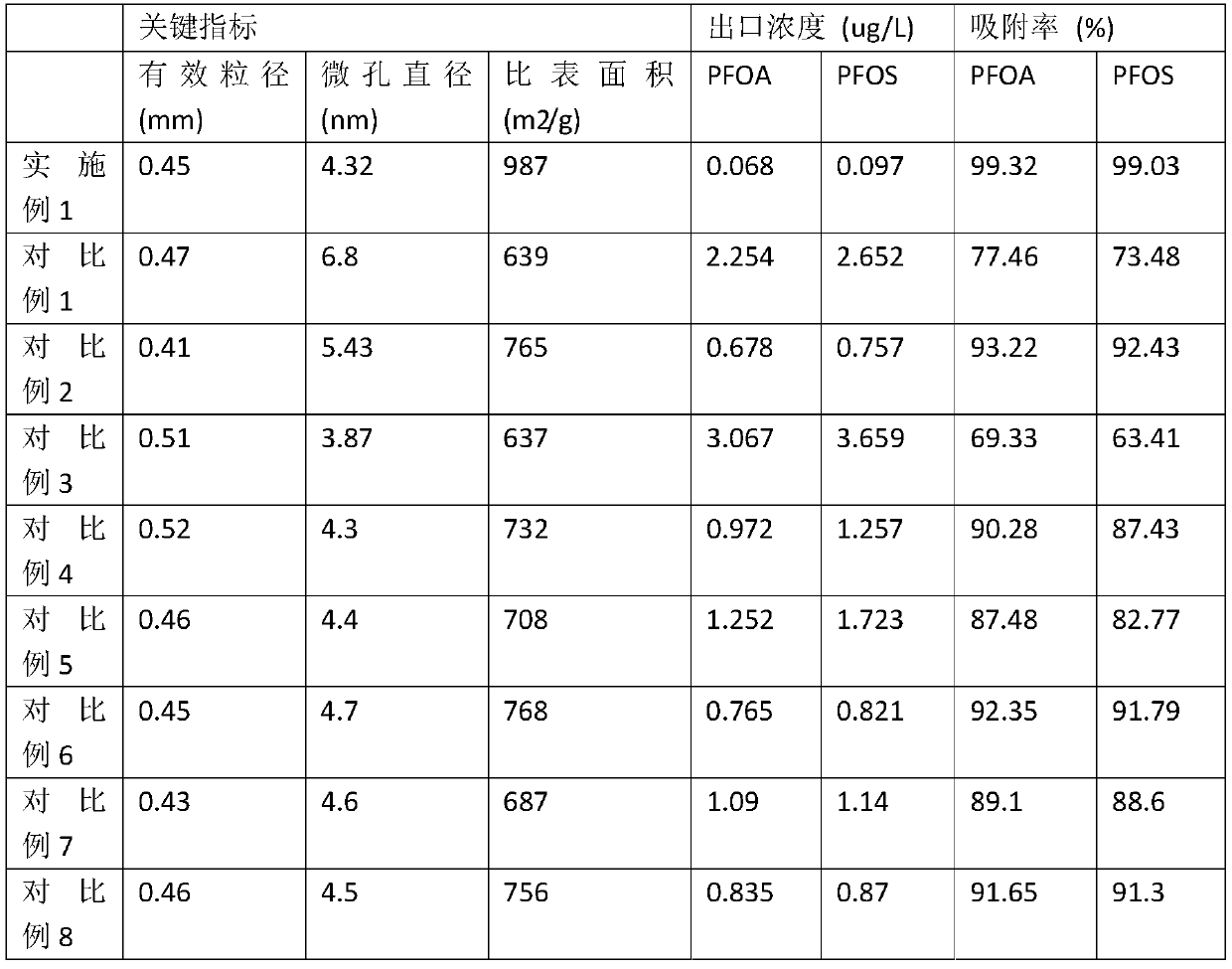

Examples

Embodiment 1

[0017] A preparation method for effectively removing perfluorinated pollutant adsorption resin in water bodies, the specific steps are as follows:

[0018] Step one suspension polymerization:

[0019] Accurately weigh 500 grams of deionized water and 4 grams of polyvinyl alcohol in the reactor according to the water phase formula, raise the temperature to 40-50 ° C, start stirring to mix all the raw materials evenly; accurately weigh in a beaker according to the oil phase formula: Divinylbenzene 100 grams, toluene 120 grams, benzoyl peroxide 1 gram, mix well;

[0020] After standing the water phase for 20 minutes, slowly add the oil phase; adjust the stirring speed so that the size of the oil droplets is distributed at 45-20 mesh; raise the temperature to 75°C, keep it warm for 3 hours, then raise the temperature to 82°C, keep it warm for 4 hours, then raise the temperature to 87°C, Keep warm for 4 hours, and the reaction is terminated;

[0021] After suction filtration, boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com