Twill woven cool-feeling fabric

A technology of cool-feeling fabrics and woven weaving, which is applied in textiles, fabrics, textiles, and papermaking, and can solve problems such as low efficiency, high elasticity of fabrics, and backward processing technology of cool-feeling fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

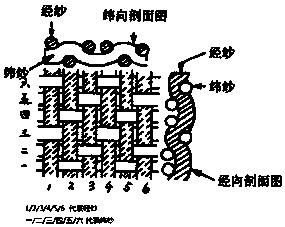

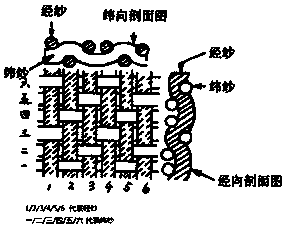

[0031] see figure 1 It can be seen that the processing method of twill woven cool feeling fabric is as follows:

[0032] Step 1: Prepare 75D / 72F superfine fiber polyester with good moisture absorption and perspiration function as the warp yarn, prepare two 70D / 48F modified nylon 6 filament double-sprayed yarns with good contact cooling performance and excellent hand feeling The thread is the weft yarn; 70D / 48F means that there are 48 fibers in the 70D thick and thin yarn; 100D / 144F means that there are 144 fibers in the 100D thick and thin yarn, and the 70D / 48F modified nylon 6 filament is spun through spinning;

[0033] Step 2: The cooling layer is made of 70D modified nylon 6 filament and 75D superfine fiber polyester through twill weaving, and the weaving equipment is two or more water jet looms;

[0034] Step 3: Woven acid dyeing technology, at low temperature, the cool silk is evenly colored and soft to the touch; during the dyeing process, the addition of color fixing a...

specific Embodiment 3

[0036] see figure 1 It can be seen that the product fabric produced by this technology has an instant cool feeling, the national standard is ≥0.17W / cm², and this product reaches more than 0.3W / cm². It adopts innovative woven acid dyeing technology. During the dyeing process of soft and cool-feeling woven fabrics, the addition of color-fixing agents improves the problem of non-standard color fastness and light fastness of nylon. Cool-feeling woven fabrics are characterized by instant contact with coolness (Qmax value) That is, the instantaneous heat flux of the fabric is expressed in Watt (W / cm²) per square centimeter.

[0037] Specific implementation 4:

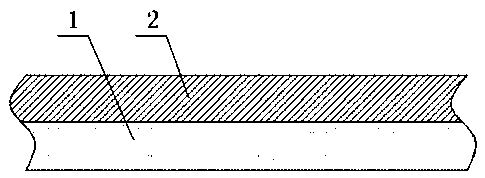

[0038] see figure 1 , figure 2 It can be seen that the woven cool fabric includes: 75D / 72F superfine fiber polyester warp yarn, two 70D / 48F modified nylon 6 filament double sprayed as the weft yarn, the cool fabric is made of warp and weft yarns interwoven through twill weave, modified The cool-feeling yarn is 70D modifi...

specific Embodiment 5

[0040] see figure 1 , figure 2 It can be seen that 70D / 48F means that there are 48 fibers in the 70D thick and thin yarn; 100D / 144F means that there are 144 fibers in the 100D thick and thin yarn. Woven cool fabrics such as figure 1 As shown, the cool feeling layer is formed by interweaving 70D cool feeling yarn and 75D polyester yarn through twill weaving, and the weaving equipment is two or more water jet looms. The present invention adopts water jet loom, twill weave, innovative The weaving method is used to improve the coolness of the fabric under the premise of ensuring the hand feeling of the fabric, and to avoid the lack of elasticity of the fabric and poor sewing. The cool yarn is composed of two 75D / 48F nylon 6 side by side. The warp yarn 75D / 72F superfine fiber polyester is an existing product. This yarn is selected because of the capillary action of the superfine fiber, which can play a good moisture absorption and quick-drying performance. At the same time, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com