Woolen yarn modification treatment process for preventing woolen yarns from being excessively hard

A treatment process and wool technology, applied in the field of wool modification treatment technology, can solve the problems of softener detachment, easy deformation of wool fabrics, and failure of cellulose to restore a soft state, so as to achieve difficult desorption, avoid irreversible deformation, and ensure resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

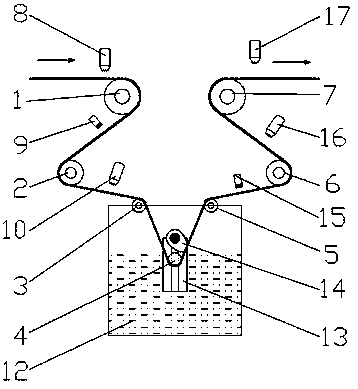

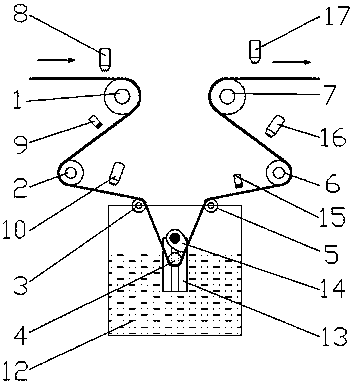

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0031] A wool modification treatment process to prevent the wool from being too hard, including the following process steps: 1) soaking the wool with hot steam, 2) rolling and brushing the wool with lye, 3) spraying urea to stick the wool, 4) soaking the wool in a softener solution, 5 ) Detergent roller brush wool, 6) acetic acid water spray wool, 7) dry hot air to dry.

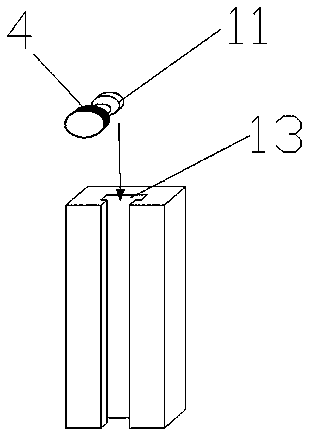

[0032] Wherein, the method of soaking the wool with the softener solution in step 4) is specifically, alternately soaking the wool from the liquid surface of the softener solution and under the liquid surface according to a certain frequency, and alternately soaking by snorkeling.

[0033] refer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com